With over 40 years of application experience, our knowledgeable staff are always available. Please contact us on 01386 421 005

We will be more than happy to help, so please call today!

For ultimate precision, repeatability and superb product quality ABSSAC only supplies KSS Ball screws manufactured in Japan. This superb product is manufactured by a grinding process and are used where acute linear accuracy is paramount within an application.

Offering a quality program of metric threaded screws, with a variety of standard and bespoke ball nut designs. Diameters from 1.8mm to 16mm and leads of 0.5mm to 30mm are available with accuracies of C0-0 to C5-10.

All ground ball screws can be supplied cut to length, with end journals machined ready to fit into an application.

Call Phil Jones, our ball screw specialist for further information. 01386 421 005

C3 accuracy = Zero-Backlash

C5 accuracy = 5 microns max backlash

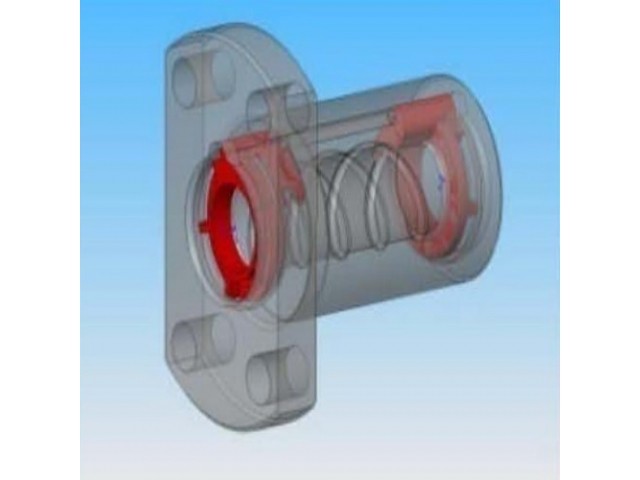

In March 2008 KSS launched a new end deflection series, which recirculates the ball bearings in the end plate of the ball nut. This design not only reduces the length of the ball nut but reduces the cost as well. The new FEB and FDB series are available in diameters of 6, 8, 10 and 12mm with leads ranging from 2.5 to 10mm. As standard this new series offers up to C3 lead accuracy and a full end machining capability.

Please also note that we offer the capability to supply custom designs to suit the application.

If you are interested in the using the transport ball screw ranges, do not forget that we also supply the full range of linear guides and rails which can provide the load support in your linear mechanism. Offering excellent rigidity and parallelism during operation the guides can be used in both vertical and horizontal planes.

If you are interested in the using the transport ball screw ranges, do not forget that we also supply the full range of linear guides and rails which can provide the load support in your linear mechanism. Offering excellent rigidity and parallelism during operation the guides can be used in both vertical and horizontal planes.

Following the link to that product page Guides

Our machining capability gives you a high journal concentricity product and can be applied to all screws regardless of diameter. Lets work together to reduce your scrap rates and supply ball solutions that fit your application every time. We can work directly from your dimensional drawings or if they do not exist, why not supply us with a physical sample for us to copy. Although all types of end machine detail can be supplied we offer a very cost effective basic end journal machining that fits our range of support bearings

.jpg) Please do not forget to ask for our competitive support bearing prices !

Please do not forget to ask for our competitive support bearing prices !

If you require further technical information, please do not hesitate to contact our sales engineers who will be more than happy to help you with your selection.

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details. Grease features include, Temperature range -30°C to 150°C, Revolutionary multi-complex soap technology, Greatly extended lubrication intervals typically 3 times longer than conventional soap thickened greases, Good corrosion resistance. Some greases are supplied blue in colour for high visibility.