With one of the most diverse and capable ball screw ranges on the market, ABSSAC is considered for a large breadth of linear challenges by its customers. The choice empowers the capability to meet most linear challenges head on, but most importantly, within budget.

For many decades our preferred supplier, KSS Co of Japan has been chosen for the precision rolled and ground ball screws for diameters from 1.8mm to 16mm. KSS Co offer second to none manufacturing techniques, unmatched quality assurance and reliability. Any precision linear application would benefit from the quality assured product range, giving peace of mind at a competitive price.

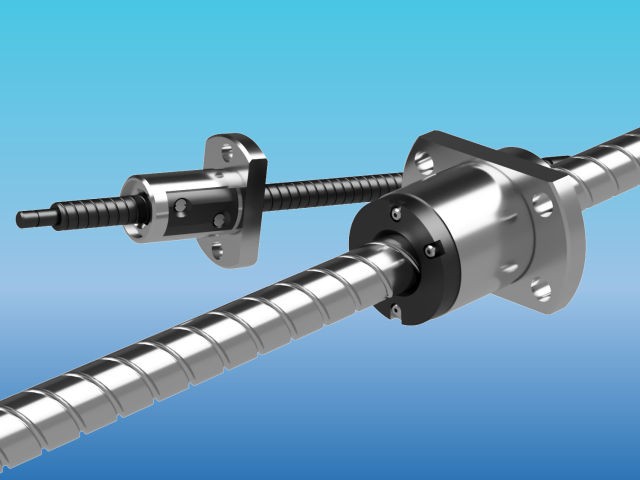

For large diameters ball screws, ABSSAC offers an excellent range of Industrial class ball screws encompassing screw diameters from 12mm up to 80mm as standard with C7 accuracy. As the product name suggests, Transport ball screw points at the more industrial type applications with dynamic load capacities from 900 to 13449 kgf being catered for, without loss of accuracy and efficiency or high drive torque. Stocked screw lengths of Transport ball screws of up to 4500mm are available up to 32mm in outside diameter and screw lengths up to 5600mm long for screws above 40mm in outside diameter.

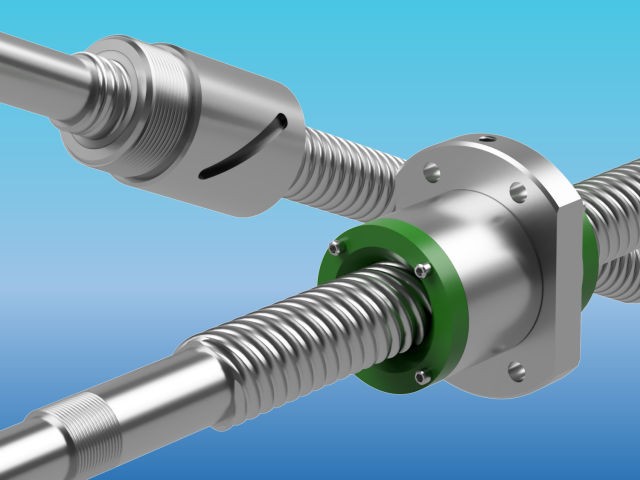

Lastly, in the portfolio, is the capability to produce unique, application specific ball nuts. By looking at how the actual nut fits within the application or other functions that the nut could achieve during operation has often lead to a reduction in parts with the linear design.

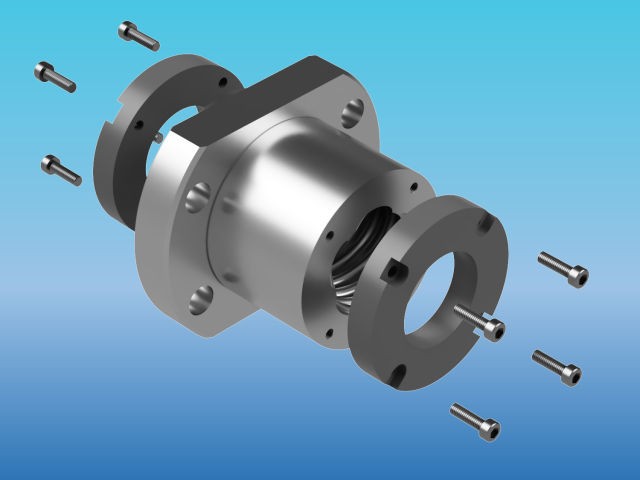

As an established supplier of ball screws, including support bearings and other related ancillary products and provides the expertise in assuring engineers that they are specifying the correct linear products for their applications. All ball screws supplied from ABSSAC can be delivered with the journal ends of the screws machined to print, so that the parts are ready to fit into the suitable bearing or application. This eliminates potential scrap rates for the customer but also ensures that the assemblies are supplied and certified to the accuracy tolerances required.

Precision, reliability, quality, value for money and on time delivery, are all things ABSSAC put at the heart of the ball screw ranges they supply and with existing customers enjoying a 98% satisfaction in a recent survey, they are rightly proud of their track record.

To make life simple ABSSAC separates the ball screw ranges into the following distinct ranges.

Ball screws that have been cold rolled formed are ideal for applications that do not require the finite accuracy of the ground ball screw equivalents, but are still required to reliably transmit a linear load with a high degree of repeatable accuracy. Utilising a wide range of ball nut designs, diameters from 4mm to 80mm and leads of 1mm to 50mm are available with accuracies of C7 to C10. All rolled ball screws can be supplied cut to length, with end journals machined ready to fit into an application.

ABSSAC offers an Industrial ball screw range that effectively converts high torque rotary input into precise high load linear movement. All industrial ball screws can be delivered cut to length and if required, machined ready to fit into the required support bearing mounts. Utilising the recirculating ball bearing nut technology as the base of the product, the Industrial class ball screws encompass screw diameters from 10mm up to 80mm as standard with C7 accuracy. Leads of 1mm to 50mm are available through a large range of ball nut designs which in many cases utilise multiple ball circuits to achieve greater load capacities

Ball screws that have been formed by a grinding process are used where acute linear accuracy is paramount within an application. We offer a quality program of metric threaded screws, with a variety of standard and bespoke ball nut designs. Diameters from 1.8mm to 16mm and leads of 0.5mm to 30mm are available with accuracies of C0 to C5. All ground ball screws can be supplied cut to length, with end journals machined ready to fit into an application.

The nut in any ball screw application is essentially a device that constrains relative motion to a desired motion, and does so with minimal friction between the moving parts. Therefore the match between the screw thread and the nut thread is critical and ABSSAC only supplies ballscrew and nut threads that are matched to give optimum performance. ABSSAC have standard nut designs to suit most linear applications, but when a nut design requires additional attachment or function ABSSAC’s linear engineers can also help find a solution.

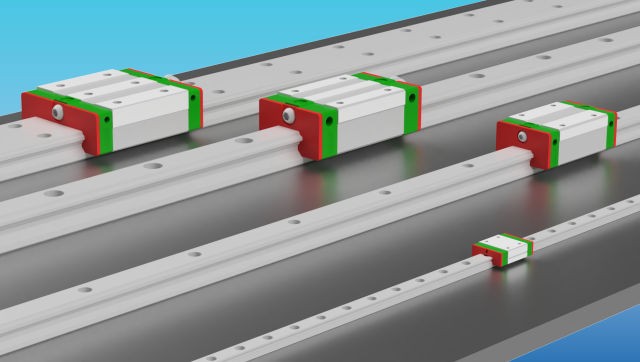

Concentrating on the flanged mount and square mount versions of linear guides, has proven to be the best linear guide solution when teamed up with any of ABSSAC’s ball screw products. By primarily using a four ball path design, within the slide, allows the guides to accept up to 30% more load and be up to 30% stiffer than similar products in the market. The designs have the ball bearings retained within the housing so that should the guides come off the end of the rail, the customer will not be faced with all the ball bearings falling out. This advantage can also significantly aid in the final assembly. A recent application utilised a Stainless Steel set up within a food processing plant. A standard linear rail of 30mm wide and 2 metres long along with a slightly preloaded Stainless Steel narrow type block carriage enabled a 20kN dynamic load to be accurately moved. Supplied with pre-drilled mounting holes both price and delivery secured the order.

Supplying ball and lead screws ready to fit into applications often requires ABSSAC to supply product to a customer drawing specification. Employing turning, grinding, milling and straightening techniques optimises the final product. Reverse engineering projects are also welcomed.

Precision thrust and radial bearing units are stocked and have proven to be an ideal partner for our range of lead, ball, satellite roller and self reversing screws. The complete thrust bearing kits contain the bearing housing, bearing set, cover, spacer, seal, locknut and set screw. By investing in large stocks gives ABSSAC the advantage to supply, at very competitive prices, pillow block and flange mounted bearing types that are interchangeable with leading brands. Available in both flanged and pillow block versions that cater for shaft sizes from 2mm up to 40mm. Other sizes are available on request.

A recent application for ABSSAC specified a precision ball screw within an electronic microscope that placed a precision guillotine against test pharmaceutical materials. Extremely fine slithers of test material are then cut off the material in rapid succession for microscopic investigation. A small variance in the sliced materials overall thickness would have had a detrimental effect on the accuracy of the microscopes results.The low friction within ball screw designs means that a high mechanical efficiency is delivered compared to that of lead screw designs. A typical ball screw may be 90 percent efficient, versus 50 percent efficiency of a lead screw of equal size. Ball screw specification is often a result of an applications requirement to have smooth, accurate and repeatable linear movement.

The application demanded a high degree of repeatable accuracy and a precision ball screw could also satisfy the other design prerequisites for it to be compact, quiet and cost effective. By using precision ground ball nuts and then pairing them with precision cold rolled ball screw threads, ABSSAC will provide a ball screw with lead accuracies of less than 52 microns of error for 300mm of linear travel. By utilising both ground nuts and rolled screws formats enabled large cost savings, when compared against a completely ground ball screw equivalent.

ABSSAC is often asked about the life expectancy of the ball screw products it supplies within applications. Whilst this can sometimes be a difficult thing to accurately calculate, as parameters within an application can change during its life, it can nevertheless be achieved. During a recent design brief with one of our packaging machinery customers, a new range of machines were being designed with exceptionally long MTBS. (mean time between service). In fact, the machines unique selling point was to be its reliability and long service intervals. The ball screw to be used would also provide the primary linear movement required within the design, so was a critical part of the design guarantee.

Typically our ball screws are rated for millions of mm’s of travel at the rated dynamic load. This is the load at which 90% of a group of identical ball screws will run without flaking for their lifetime. However, they will travel farther than this at lower limits. These load-life relationships are analogous to the B10 rating common in the ball bearing industry. The relationship of load to life is an inverse cube relation. For example, by reducing the customers load by half would increase the life by eight times. (Conversely doubling the load would decrease life by 1/8).