With over 40 years of application experience, our knowledgeable staff are always available. Please contact us on 01386 421 005

We will be more than happy to help, so please call today!

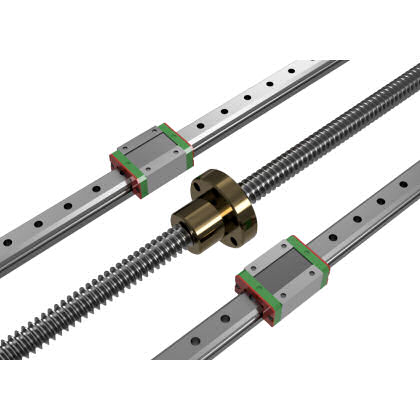

The Transport Industrial ball screw range effectively converts high torque rotary input into precise high load linear movement for the more arduous applications. All transport ball screws can be delivered cut to length and if required, machined ready to fit into the required support bearing mounts.

Utilising the recirculating ball bearing nut technology as the base of the product, the Industrial class ball screws encompass screw diameters from 12mm up to 80mm as standard with C7 accuracy. Leads of 1mm to 50mm are available through a large range of ball nut designs which in many cases utilise multiple ball circuits to achieve greater load capacities. Making the product suitable for many types of application.

Typically the Transport ball screws are rated for millions of mm’s of travel at the rated dynamic load. This is the load at which 90% of a group of identical ball screws will run without flaking for their lifetime. However, they will travel farther than this at lower limits.

As the name suggests, the range is aimed at the more industrial type application with dynamic load capacities from 900 to 13449 kgf being catered for. Whatever the load, it will be delivered with both high efficiency and low drive torque. Stocked screw lengths of up to 4500mm are available up to 32mm diameter and screw lengths up to 5600mm long for screws above 40mm in diameter.

ABSSAC is often asked about the life expectancy of the ball screw products it supplies within applications. Whilst this can sometimes be a difficult thing to accurately calculate, as parameters within an application can change during its life, it can nevertheless be achieved. During a recent design brief with one of our packaging machinery customers, a new range of machines were being designed with exceptionally long MTBS. (mean time between service). In fact, the machines unique selling point was to be its reliability and long service intervals. The ball screw to be used would also provide the primary linear movement required within the design, so was a critical part of the design guarantee.

Typically our Transport ball screws are rated for millions of mm’s of travel at the rated dynamic load. This is the load at which 90% of a group of identical ball screws will run without flaking for their lifetime. However, they will travel farther than this at lower limits. These load-life relationships are analogous to the B10 rating common in the ball bearing industry. The relationship of load to life is an inverse cube relation. For example, by reducing the customers load by half would increase the life by eight times. (Conversely doubling the load would decrease life by 1/8). Armed with this information ABSSAC’s customer then made every attempt to reduce the load within the design, which after a great deal of design change was finally achieved. The end result was a ball screw assembly with the life expectancy required by the customer.

ABSSAC can supply Transport Ball Screws in the following sizes. Ball Screw shaft lengths are available at the maximum lengths listed below

Our machining capability gives you a high journal concentricity product and can be applied to all screws regardless of diameter. Let us work together to reduce your scrap rates and supply ball solutions that fit your application every time. We can work directly from your dimensional drawings or if they do not exist, why not supply us with a physical sample for us to copy. Although all types of end machine detail can be supplied we offer a very cost effective basic end journal machining that fits our range of support bearings (see example diagrams below)

Linear guideways provide excellent load bearing linear motion by re-circulating rolling elements between a profiled rail and a bearing block. By primarily using a four ball path design, within the slide, delivers excellent rigidity and parallelism during operation. The guides can be used in both vertical and horizontal planes.

ABSSAC supplies both radial and thrust bearings, complete with housings, to compliment their expanding lead screw and ball screw ranges. All bearings include the bearing set, bearing housing, snap ring, lock nut, spacer ring and retaining cover. Available to suit all shaft sizes, the range delivers robust radial and thrust protection in any rotary or linear application. Let us help you with your selection.

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details.