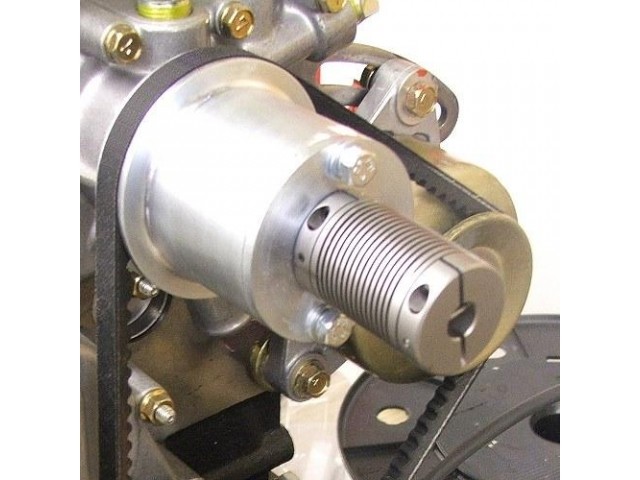

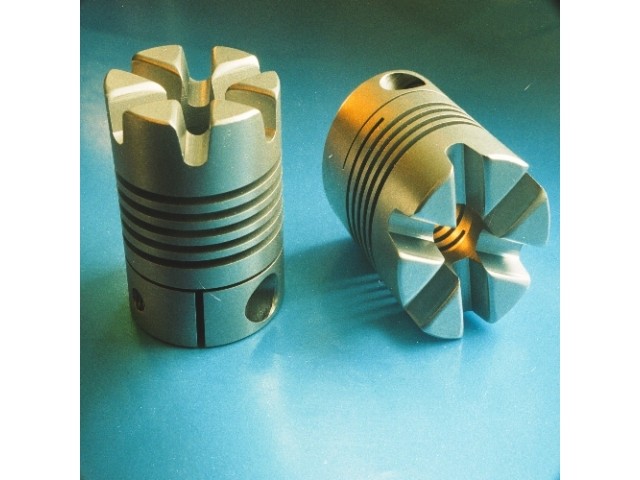

Heli-Cal Shaft couplings are an essential part of any rotary device where you need to connect a driven part without loss of registration.

Abssac supplies a single piece construction, zero backlash, constant velocity shaft coupling that simultaneously compensates for angular, parallel and skewed shaft misalignments. Available in Stainless Steel (or Aluminium) as standard with both metric and imperial bores sizes stocked ready to be delivered.

The Helical beam coupling range can also offer ways of integrating the design engineers own end attachment into the standard shaft coupling, but maintaining its one piece construction. We have had considerable success in supplying a ready to fit single construction part that can sometimes be comprised of three or more individual parts in the original design. This way our customers have saved money, time and hassle.... which is what we all want

Abssac is so confident that the award winning shaft coupling product can have an operational advantage over other styles of shaft coupling, that it is offering a free coupling to test, to prove the point.

If you require further technical information, please do not hesitate to contact our sales engineers on 01386 421005 who will be more than happy to help you with your selection.

| A Series | H Series | DS Series | MCA Series | MC7 Series | W Series | W Series |

| Aluminum 7075-T6 | Stainless Steel 17-4PH | Aluminum 7075-T6 | Aluminum 7075-T6 | Stainless Steel 17-4PH | Aluminum 7075-T6 | Stainless Steel 17-4PH |

|  |  |  |  |  |  |

| Description | ||||||

| General purpose, light to medium duty. An economical, maintenance free coupling, used in a variety of appli- cations. Helical's most popular coupling/coupler | Stainless steel version of “A” series, with higher torque capacity and torsional stiffness. Increased fatigue resistance. | Low inertia, high performance, aluminum coupling, using Helical double start technology. Torsionally stiffer and higher torque capacity than the “A“ series. Lighter with lower inertia than the “H” series. | A general purpose aluminum coupling, used where more parallel misalign- ment is required. Has a large range of shaft sizes, with optional keyways. | Stainless steel version of “MCA(C)” series, with higher torque capacity and torsional stiffness. Increased fatigue resistance. | Metric dimensions with metric fasteners. A light to medium duty coupling for those preferring to work strictly in the metric system. A general purpose coupling. | Stainless steel version of the “WA(C)“ series, with higher torque capacity and torsional stiffness. Increased fatigue resistance with all metric dimensions and fasteners. |

| Typical Applications | ||||||

| Used for encoder/ resolver applications, low torque pump, lead screw and various other applications. | For situations requiring a heavy duty coupling such as pumps, lead screws, and positioning systems; also for process equipment in industrial situations. Anywhere a rugged, tough, long-lasting coupling is needed. | For high speed motion control systems, where fast response time is important. E.g., lead and ball screws, encoders/ resolvers, and anywhere high torsional stiffness is required. | Good for encoder/resolver applications, moderate torque pump, lead screw, and various other applications. | Good for pump, conveyor systems, and industrial processing equipment, where absolute reliability is required. Anywhere a rugged, tough, long-lasting coupling is needed. | Used for encoder/resolver applications, low torque pump, lead screw and various other applications. | For situations requiring a heavy duty coupling, for pump, lead screws, and positioning systems. Also for process equipment in industrial situations. Anywhere a rugged, tough, long-lasting coupling is needed. |

| Misalignment Compensation | ||||||

| 5° angular, .010 inch parallel offset, .010 inch axial motion | 5° angular, . 010 inch parallel offset, .010 inch axial motion | 3° angular, .010 inch parallel offset, .008 inch axial motion | 5° angular, .030 inch parallel offset, .010 inch axial motion | 5° angular, .030 inch parallel offset, .010 inch axial motion | 5° angular, .25mm parallel offset, 25mm axial motion | 5° angular, .25mm parallel offset, .25mm axial motion |

| Torque Range | ||||||

| 1.2-51 lbin | 2.4-100 lbin | 12-234 lbin | 20-286 lbin | 40-556 lbin | .59-20 Nm | 1.2-39 Nm |

| Standard Bores (inch and or metric bores available in all couplings) | ||||||

| 0.059-0.750 inch 1.5-19.05mm | 0.059-0.750 inch 1.5-19.05mm | 0.188-0.750 inch 4.78-19.05mm | 0.250-.875 inch 6.35-22.23mm | 0.250-1.000 inch 6.35-25.40mm | 3mm-38.1mm | 3mm-38.1mm |

| Attachment | ||||||

| Clamp or set screw | Clamp or set screw | Clamp | Clamp or set screw Keyways optional | Clamp or set screw Keyways optional | Clamp or set screw | Clamp or set screw |

| Operating temperatures | ||||||

| Up to 200°F | Up to 600°F | Up to 200°F | Up to 200°F | Up to 600°F | Up to 100°F | Up to 300°F |

| Speed (in the wind up direction) | ||||||

| 10,000 rpm | 10,000 rpm | 10,000 rpm | 3,600 rpm | 3,600 rpm | 10,000 rpm | 10,000 rpm |