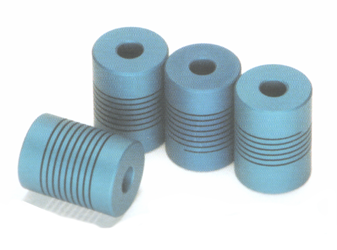

One of the greatest advantages of the Helical beam shaft coupling product is the ease in which it can be adapted from a standard and into a cost effective, multi-functional bespoke design. It is the perfect solution where flexibility is required for critical applications. Shown below is the simple way that by changing the geometry of the coils affects performance of the beam coil shaft coupling.

|  |

| The Coil Width - By varying the thickness of the coils a beam coupling can accommodate increasing amounts of torque and radial loads. | The Number of Coils - When the number of beam coils are added or removed, the torque capability remains unchanged but the angular, parallel and skewed offset capability increases. |

|  |

| The Inside Diameter - When the inside diameter changes, so does the torque capacity, torsional stiffness and axial spring rate. | The Number of Coil Starts - One, two or three helical beams coils within the single piece construction delivers higher torsional stiffness. |

A single piece construction, zero backlash, constant velocity shaft coupling that simultaneously compensates for angular, parallel and skewed shaft misalignments. Available in Stainless Steel or Aluminium as standard with both metric and imperial bores sizes. ABSSAC offers a variety of customisation options that can change the torque capacity, misalignment compensation and torsional stiffness to meet the needs of your application.A wide range of materials are also available. Factors such as torque capacity, elasticity, fatigue, corrosion resistance, mass, magnetic permeability, operating temperature, availability and cost also play important roles in material selection. 17-4PH CRES*, 15-5PH, C300, BETA C Titanium and 7075-T6 Aluminium, are just a few of the common choices for meeting design and performance needs.

Various attachment methods are available. For custom beam couplings we can offer standard integral clamp or set screw attachment methods, or we can offer less standard options if it is required for your design. This can include things like pins, gears, slotted hubs, flanges and flats. ABSSAC Beam Couplings can also be engineered to accommodate a variety of custom bore options. These include standard and non standard keyways, threaded bores, square bores, tapered bores, splines or any other bore of your choice.

To find you solution please complete our Rotary Proposal Form and one of our engineers will be happy to assist you.

Our series of Form-Flex Industrial Disc Couplings are ideal for transmitting very high levels of torque with moderate levels of angular, parallel and axial misalignment. For applications where there is a larger distance between the driver and the driven components, a floating shaft can be used. Floating shafts can come in customer specified lengths, and depending on coupling size, lengths of up to 4300mm can be achieved.

Industrial Disc Couplings are available in a variety of specialised materials on request. ABSSAC have recently supplied an incredibly light weight industrial disc coupling with a total length of over 3 metres long, to be used to drive a large industrial fan. Despite it’s size, it was required to operate at speeds of up to 1800RPM. To meet this specification the floating shaft was entirely custom made out of a carbon fibre/glass composite, and was meticulously balanced to ensure maximum performance at high speed. The hubs were made out of high grade stainless steel. This is a perfect example of no matter what the requirement is, ABSSAC will explore every avenue of customisation possible to make your specification. To find you solution please complete our Rotary Proposal Form and one of our engineers will be happy to assist you.

The Flexure is an advanced and unique u-joint solution that generally exceeds the capabilities of common u-joint designs. A Flexured U-Joint may accommodate up to 90° of angular shaft misalignment in certain circumstances. Which is something not easily achieved by a conventional U-Joint. U-joints are used in a variety of applications, wherever handling significant angular misalignment is the main focus. Typical applications include articulating mechanisms, food processing equipment, replacement for expensive gearboxes and drives where motor position must be moved angularly of the centreline of the driven unit. The performance capability of each flexure is determined by characteristics such as: flexure outside diameter, inside diameter, coil thickness, material, number of coils, and number of starts. By altering these parameters, Flexured U-joints can be made to suit specific specifications and/or requirements.

Key product advantages include:

To find you solution please complete our Rotary Proposal Form and one of our engineers will be happy to assist you.

All ETP products consist of a double-walled hardened steel (in some cases stainless steel) sleeve, filled with a pressure medium. When the pressure screw is tightened a high surface pressure is created against the shaft and hub, causing the locking effect. Whether the hubs are to be removed or repositioned, the mounting and dismantling process can be done in a few seconds. Standard ETP products can be adapted, or when necessary, completely engineered to provide bespoke designs.

Ideal for those high torque, high parallel shaft offset applications. The proven Schmidt shaft coupling program delivers high performance torque transmission. Through a full customisation program the product can offer unique technical advantages to the user.

Universal Joints are particularly efficient at transmitting torque through greater shaft offset angles than a standard shaft coupling design can. We can offer full customization of the standard product with full application certification.

Although the range of standard clutches and brakes on offer will suit 99% of applications, we have also developed innovative solutions to suit individual applications. This can be as simple as a bespoke attachment design on a standard part through to a complete tailored clutch of brake solution. If the demand is there, we are happy to explore new designs that can give your application leading edge technology in braking and clutch control. Why not call one of our engineers to discuss further.

By simply allowing the development of innovative connection solutions from the standard beam shaft coupling design, has opened up a plethora of opportunities to the design engineer. The hidden potential of expanding how a shaft coupling physically connects within an application, which is often left to standard grub screw or locking clamp, can enhance the overall efficiency of an application. With Abssac’s beam coupling product, customers have been able to take their standard coupling designs to the next level, by incorporating features into the original shaft coupling design. In many cases, the final shaft coupling design is an amalgamation of separate parts that include such items as external gears, splines, threads and tangs. However, most importantly, it enables the design engineer to achieve far greater usage from one item in the total machine which inevitably leads to greater efficiency. How the standard shaft coupling connectability is enhanced, is really up to the designer.

By simply allowing the development of innovative connection solutions from the standard beam shaft coupling design, has opened up a plethora of opportunities to the design engineer. The hidden potential of expanding how a shaft coupling physically connects within an application, which is often left to standard grub screw or locking clamp, can enhance the overall efficiency of an application. With Abssac’s beam coupling product, customers have been able to take their standard coupling designs to the next level, by incorporating features into the original shaft coupling design. In many cases, the final shaft coupling design is an amalgamation of separate parts that include such items as external gears, splines, threads and tangs. However, most importantly, it enables the design engineer to achieve far greater usage from one item in the total machine which inevitably leads to greater efficiency. How the standard shaft coupling connectability is enhanced, is really up to the designer.

Abssac’s customer had an application where a precision encoder was being connected to a carpet manufacturing machine output shaft. The machines are used to manufacture man-made fibre twisted loop pile carpets for domestic use. If the vibration and movement present at the output shaft was transmitted to the encoder, it would cause signal errors and ultimately prematurely destroy the encoder. Ultimately this would lead to below standard carpet being produced due to loom operational irregularities. Whilst very little torque was required in the application, torsional stiffness and zero backlash were important design parameters. The customer also wanted a low maintenance solution.

Abssac’s customer had an application where a precision encoder was being connected to a carpet manufacturing machine output shaft. The machines are used to manufacture man-made fibre twisted loop pile carpets for domestic use. If the vibration and movement present at the output shaft was transmitted to the encoder, it would cause signal errors and ultimately prematurely destroy the encoder. Ultimately this would lead to below standard carpet being produced due to loom operational irregularities. Whilst very little torque was required in the application, torsional stiffness and zero backlash were important design parameters. The customer also wanted a low maintenance solution.

From a coupling design aspect, the application required large axial motion and parallel misalignment because of the assembly tolerances. The customer was originally using a multi-part bellows shaft coupling, but the required angular and axial movements lead to premature failure. Additionally, under certain operating conditions, the bellows coupling allowed too much vibration to reach the encoder.

The solution was found using an adapted flexible beam shaft coupling. A low inertia Aluminium part was created using two flexible beam elements in the single piece design. Two integral clamps held the shafts, each flexible element allowed for the maximum angular and axial offsets set by the customer but also maintained a high degree of torsional stiffness. A working sample was then sent for test and evaluation. Testing proved very successful and verified the new coupling design provided better isolation of the encoder from the motor and better performance. Subsequent machines are now being fitted with the low cost, long term solution.

Abssac recently enhanced the operation of a medical orthodontic machine by replacing a universal joint, plastic shaft coupling and a piece of shafting with just a one piece flexured drive shaft unit. Abssac's customer had initially been using a traditional universal joint to connect a hand control, via a piece of shaft and through another plastic flexible shaft coupling, to a small gear box. The universal joint was expensive and was being utilised at the limit of its angular capability, which was causing cyclic torque variants on operation. A separate piece of bar stock was then used to span the drive mechanism to the gear box, which again required 3 degree shaft misalignment, which was accommodated by a small plastic multipart shaft coupling. The old design was inefficient, time consuming to build and had suffered from reliability issues. Abssac's solution was to take 400mm of Aluminium bar stock, 15mm in diameter, which would provide the length requirement of the drive shaft.

Abssac recently enhanced the operation of a medical orthodontic machine by replacing a universal joint, plastic shaft coupling and a piece of shafting with just a one piece flexured drive shaft unit. Abssac's customer had initially been using a traditional universal joint to connect a hand control, via a piece of shaft and through another plastic flexible shaft coupling, to a small gear box. The universal joint was expensive and was being utilised at the limit of its angular capability, which was causing cyclic torque variants on operation. A separate piece of bar stock was then used to span the drive mechanism to the gear box, which again required 3 degree shaft misalignment, which was accommodated by a small plastic multipart shaft coupling. The old design was inefficient, time consuming to build and had suffered from reliability issues. Abssac's solution was to take 400mm of Aluminium bar stock, 15mm in diameter, which would provide the length requirement of the drive shaft.

Then using the unique ability to adapt the "flexure" or beam part of the shaft coupling, they could provide the two angular misalignments required in the system, but all within the single part. Utilising a double start coil flexure at each end to give the superior torsional stiffness, the drive shaft could accept angular misalignment up to 30 degrees at one end, whilst the other end would accept up to 5 degrees. The final design incorporated a split clamp design to lock the drive shaft into position onto the driven and drive ends. The new design was then used in 4 other machines using different lengths as the single part provided a zero-blacklash drive solution, which did not require lubrication, maintenance or suffered from operational issues.

.jpg)

Miniature designs are a growing part of our business as components become smaller and demand more function. A fully functional 3.1mm diameter shaft coupling was recently supplied for a medical application. Using a left and right handed thread shaft for attachment the coupling could accept up to 1mm of angular offset rotating up to 10,000 rpm. The same customer is now looking at a double start flexure with a 1.5mm outside diameter produced in titanium.

With any flexible beam coupling design it is imperative that the start and finish of the coil slit is finished smoothly and without scarring or swarf residue, as this will shorten the working life of the shaft coupling dramatically. The way in which other similar designs are manufactured results in a relatively sharp edge that may act as a stress riser during operation. In certain cases this stress riser is where a crack will form and most likely lead to a complete failure of the part. Apart from superior manufacturing techniques , as standard, all shaft couplings are shot peened and hard anodised to further reduce the stress raisers within the coupling to make a more reliable part. For the more arduous of applications we have invested in the technology to incorporate a stress relief hole that reduces the stress concentration the coil finish to the solid hubs. Incorporating a stress relief hole reduces the stress concentration by taking the existing sharp edge and modifying it to be a smooth transition from the coil end to the solid hubs. A stress relief can drastically increase the life of the shaft coupling.

With any flexible beam coupling design it is imperative that the start and finish of the coil slit is finished smoothly and without scarring or swarf residue, as this will shorten the working life of the shaft coupling dramatically. The way in which other similar designs are manufactured results in a relatively sharp edge that may act as a stress riser during operation. In certain cases this stress riser is where a crack will form and most likely lead to a complete failure of the part. Apart from superior manufacturing techniques , as standard, all shaft couplings are shot peened and hard anodised to further reduce the stress raisers within the coupling to make a more reliable part. For the more arduous of applications we have invested in the technology to incorporate a stress relief hole that reduces the stress concentration the coil finish to the solid hubs. Incorporating a stress relief hole reduces the stress concentration by taking the existing sharp edge and modifying it to be a smooth transition from the coil end to the solid hubs. A stress relief can drastically increase the life of the shaft coupling.