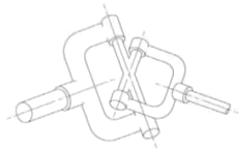

A single piece construction, zero backlash, constant velocity shaft coupling that simultaneously compensates for angular, parallel and skewed shaft misalignments. Available in Stainless Steel or Aluminium as standard with both metric and imperial bores sizes stocked ready to be delivered.

By varying the thickness of the coils, a Flexure can accommodate increasing amounts of torque and radial loads. The designer may specify torsional stiffness and compression spring rates independent of other factors.

The individual performance capability of each Flexure is detemined by: coil width, inside diameter, number of coils, number of starts and material. Altering any one of these factors changes the performance characteristics of the “Flexure”.

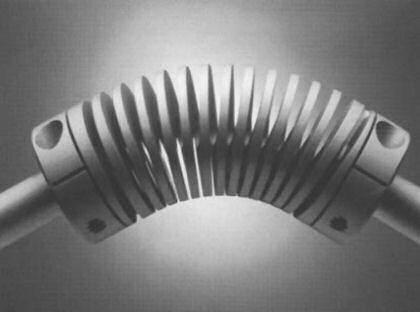

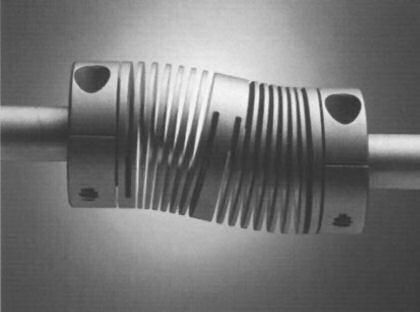

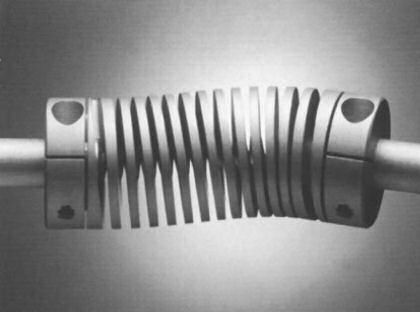

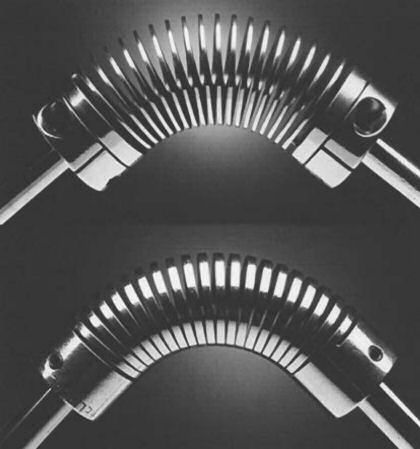

For example, the HELI-CAL Flexures illustrated display identical outside diameters and lengths. The effects of their variable characteristics- such as coil width, inside diameter, number of coils and starts are explained in the adjacent pictures.

As the coil width or inside diameter are changed sich aspects as torque...angular misalignment (bending moment)...parallel offset (radial load)... torsional stiffness... and compression spring rate, are altered.

As the number of coils is changed, all of the characteristics except the torque capacity are affected.

When the inside diameter changes, so does the torque capacity, torsional stiffness and axial spring rates.

When a multi-start helix is used (double or triple), the effect is to increase the torque capacity and torsional stiffness while reducing misalignment capabilities (angular and parallel).

The proper material used in the manufacture of any HELI-CAL Flexure affects much more that just torque capacity. Factors such as elasticity, fatique, corrosion resistance, mass, magnetic permeability, operating temperature, availability and cost also play important roles. High strength materials such as 17-4PH CRES*, 15-5PH, C300, BETA C Titanium and 7075-T6 Aluminium, are just a few of the common choices for meeting design and performance needs.

When the number of coils is changed the torque capability remains unaffected. All of the other characteristics change.

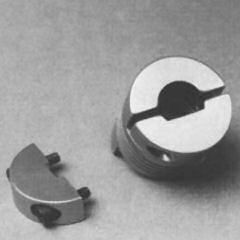

In addition to being able to alter the characteristics of the HELI-CAL Flexure, you may have your attachment method integrated into the final product.

Typical attachment options might include:

Multiple, (typically two) helical beams provide high torsional stiffness. Shown: single, double and triple start.

Helical Flexures may be engineered to include a variety of bore configurations. These variations include round, threaded, single or double-D, spline, keyway, tapered or ... your choice!

The HELI-CAL Flexure or flexible coil section of the coupling can be custom designed and manufactured to your specifications. Whether your considerations include high torque, angular or parallel misalignment, critical torsional stiffness, precise compression spring rates, or special end connections, chances are excellent that the HELI-CAL Flexure will meet or exceed your particular design requirements.

The HELI-CAL Flexure concept brings enormous design flexibility to your applications. Depending on your needs, the flexure can serve as a flexible shaft coupling, universal joint, machined spring or your own specialised component.

The Flexure's ability to accommodate various performance characteristics and its ability to integrate attachments directly enhances your freedom to design.

Not only does the Flexure integrate multiple functions and parts into a single compact unit - no moving parts, no maintenance and no backlash - it can incorporate complex attachments.

High quality performance is achieved with magnetic or non-magnetic corrosion-resistant stainless steel, as well as aluminium alloys. Flexures are also successfully manufactured using various materials such as Delrin™ and titanium.

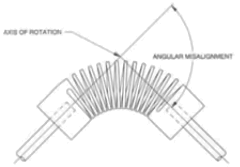

The flexing capactiy of the HELI-CAL Flexure can compensate for a variety of misalignments, including parallel, angular and skewed (three-dimensional) misalignment. The Flexure solutions for these misalignment situations are shown in the adjacent photographs.

Angular misalignment is the easiest form of misalignment for most couplings to accept, and thus one of the most practical applications of a flexible coupling. Allowing only enough space between coils to partially close the gap during bending, the HELI-CAL Flexure can accept an angular misalignment of 20 degrees or more (and even up to 90 degrees in special ujoint applications).

The basic requirement of a flexible coupling is to transmit torque loads without permanent distortion or damage and without imposing undue bending or radial loads upon the driver or driven components. Once the working torque rating of a HELI-CAL Flexure coupling is established - based on misalignment and design criteria, material specifications and service factors supplied during the design process - its operational life is virtually unlimited.

Every flexible shaft coupling has some torsional flexibility. Torsional flexibility reflects the amount of twist in a system; torsional stiffness the degress of resistance against twist. The HELI-CAL Flexure can be configured (with thicker coils, for example), to provide the exact amount of torsional flexibility required in an application.

Parallel misalignment is the most difficult form of misalignment for couplings to compensate for. It can also be the most damaging to shafts, bearings and motors. The HELI-CAL Flexure, through lateral displacement, transforms an application's parallel misalignment problems into angular displacement within the coupling. The centre coils of the HELI-CAL Flexure can become an intermediate shaft that can allow 10, 20 or 30 thousandths of an inch of parallel offset or more.

When shafts are not in the same plane (skewed), the HELICAL Flexure’s abilities to compensate are the same as with either parallel or angular misalignment - but in the third dimension. A Flexure designed with more coils in a series can compensate for as much threedimensional misalignment as your applications requires.

Bearing loads are primarily generated by a couplings natural resistance to bending, and can be very destructive forces to an apparatus and its rotational components. The HELICAL Flexure maintains a very constant radial and bending load at all points of rotation, providing exceptionally uniform bearing loads.

In a rotating system, constact velocity refers to the relative rotational speed of the input and output shafts. In a constant velocity system the driven end of the coupling turns exactly the same rate as the driver end. When operating under a uniform load the HELICAL Flexure design provides constant velocity and alleviates:

Universal Joints A New Angle on Universal Joints Flexured U-joints Provide Precision Operating Characteristics

A universal joint is a mechanical connection between two rotating shafts, which are generally not in parallel, but are intersecting. U-joints are used in a variety of applications, wherever handling significant angular misalignment is the main focus. Typical applications include: articulating mechanisms, food processing equipment, replacement for expensive gearboxes and drives where motor position must be moved angularly off centreline of the driven unit.

CARDAN U-JOINT

HELI-CAL FLEXURE

The HELI-CAL Flexure is an advanced and unique u-joint solution that generally exceeds the capabilities of common u-joint designs. A Helical u-joint may accommodate up to 90° of angular shaft misalignment in certain circum-stances. This type of u-joint will also compensate for axial and parallel misalignment simultaneously.

The Helical Flexure is an advanced and unique u-joint solution that generally exceeds the capabilities of common u-joint designs. A Helical u-joint is really a flexure capable of over 5° of angular misalignment. It may accommodate up to 90° of angular misalignment in certain circumstances.

This type of u-joint will also compensate for axial and parallel misalignment.

The performance capability of each HELICAL Flexure is determined by characteristics such as: flexure outside diameter, inside diameter, coil thickness, material, number of coils, and number of starts. By altering these, Helical flexured u-joints can be made to suit specific specifications and/or requirements. Characteristics, torque capacity, angular and parallel misalignment capabilities, torsional and lateral bending rates of flexured u-joints can be made to suit specific specifications and/or requirements.

By using a flexured u-joint, the customer benefits from:

An added bonus - flexured u-joints do not have:

Once the designer/customer provides Abssac with the performance requirements for his/her device, machine or equipment, a specific flexure design that will meet or exceed application requirements is developed. An attachment may also be specified to securely interface with adjacent components. The result is a flexured u-joint that works as an integral part of the customer's application. Since the nature of the product requires some in-depth calculations to specify the product, please contact our sales office, who will be more than happy to assist you with your application.

The ability to adapt to high - and low-speed applications is another inherent benefit of the HELI-CAL Flexure's design. The Flexure transmits motion throughout its length and cross section in a continuous helix from end to end. Torsional loading tends to make the Flexure draw toward its centreline, reducing the chance of whipping action normally associated with rotating components. Consequently, vibrations are kept to a minimum at all rotating points.

Axial movement is inherent in any rotating components, such as the rotor assembly in a motor. Through compression/extension, the HELI-CAL Flexure absorbs and compensates for axial movement or end play. The curvedbeam structure of the Flexure operates naturally in this axial compensation mode, and special designs can accommodate for even large displacement applications. No matter what its size or shape, the flexure design assures performance, reliability, quality and versatility, arguably unmatched in the coupling industry.