Using a comprehensive range of screw diameters from 8mm through to 36mm, and combining these with two standard types of nut, (Flanged preloaded or simple flanged) results in a high integrity lead screw and nut product that is ready to be fitted directly into the application and perform.

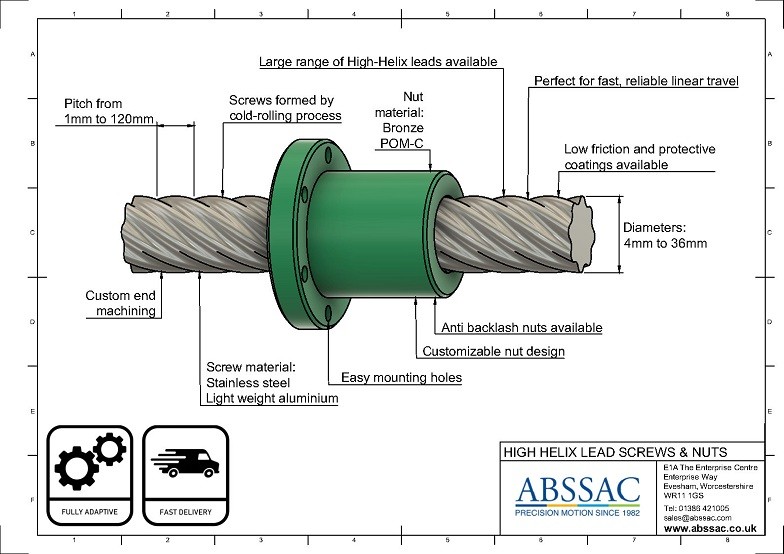

The screws can be manufactured from Steel, Stainless Steel and Aluminium whilst the associated nuts are available in wear resistant thermoplastic (Plastic Polymer Nuts: - 40 deg C to + 60 deg C) or Bronze (Bronze Nuts: - 40 deg C to + 200 deg C) for higher loads or temperature. When choosing a High helix lead screw for your application you should consider that we can offer a standard Lead Accuracy 0.21mm / 300mm or a precision Lead Accuracy of 0.10mm / 300mm.

We offer a full end journal machining service with this product, so that the product can fit suitable radial and thrust bearings.

Non-preloaded:

SFM - POM-C, Black

SBM - Bronze

Axial-preloaded, if p0 > d0:

SFV - POM-C, Black

Axial-preloaded, if p0 ≤ d0

SFT - EX100, white

| Nominal size | Dimensions | Load Rates for POM- C/EX100 (N)* | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw | Nut | |||||||||||||||||||||||||

| d0 / p0 (mm) | d1 | d2 | p | g | D1 (h8) | D2 ±0.05 | D4 | D5 | D6 | D7 | LnF | LnB | LvF | L1 | L7 | |||||||||||

| 4 / 10 | 4.0 | 3.0 | 10.0 | 8.0 | 12.0 | 11.5 | 18.0 | 3.2 | 28.0 | x | 20.0 | 15.0 | x | 3.0 | 4.0 | 150.0 | ||||||||||

| 5 / 5 | 5.4 | 3.6 | 5.0 | 4.0 | 21.0 | 20.5 | 29.0 | 4.2 | 38.0 | 18.5 | 25.0 | 18.0 | 38.0 | 3.0 | 5.0 | 300 | ||||||||||

| 5 / 20 (L) | 6.0 | 5.0 | 20.0 | 16.0 | 21.0 | 300 | ||||||||||||||||||||

| 6 / 25 | 7.4 | 6.3 | 25.0 | 20.0 | 21.0 | 400 | ||||||||||||||||||||

| 7.5 / 7.5 | 7.7 | 5.9 | 7.5 | 6.0 | 21.0 | 450 | ||||||||||||||||||||

| 8 / 4 | 7.9 | 5.5 | 4.0 | 2.0 | 24.0 | 20.5 | 23.5 | 29.0 | 32.0 | 4.2 | 42.0 | 38.0 | x | 18.5 | 950 | |||||||||||

| 8 / 10 (L) | 8.2 | 5.5 | 10.0 | 4.0 | 24.0 | 21.5 | 20.523.5 | 800 | ||||||||||||||||||

| 8 / 12 | 8.0 | 5.9 | 12.0 | 5.0 | 24.021.5 | 800 | ||||||||||||||||||||

| 8 / 15 | 8.0 | 5.9 | 15.0 | 6.0 | 24.021.5 | 850 | ||||||||||||||||||||

| 8 / 30 (L) | 8.6 | 7.5 | 30.0 | 24.0 | 21.0 | 20.523.5 | 20.5 | 29.032.0 | 29.0 | 4.242.0 | 38.0 | 38.0 | 18.5 | 18.5 | 500 | |||||||||||

| 8 / 38 | 8.0 | 5.7 | 38.0 | 8.0 | 24.0 | 20.523.5 | 23.5 | 29.032.0 | 32.0 | 4.242.0 | 42.0 | 38.0 | 21.5 | 18.5 | 1000 | |||||||||||

| 9 / 20 | 8.9 | 5.8 | 20.0 | 5.0 | 24.0 | 850 | ||||||||||||||||||||

| 10 / 10 | 10.0 | 8.2 | 10.0 | 8.0 | 24.0 | 600 | ||||||||||||||||||||

| 10 / 12 (L) | 10.0 | 7.1 | 12.0 | 4.0 | 24.0 | 1200 | ||||||||||||||||||||

| 10 / 15 | 10.0 | 7.4 | 15.0 | 5.0 | 24.0 | 1200 | ||||||||||||||||||||

| 10 / 35 (L) | 10.1 | 8.9 | 35.0 | 28.0 | 24.0 | 600 | ||||||||||||||||||||

| 10 / 50 (L) | 10.0 | 7.4 | 50.0 | 10.0 | 26.0 | 20.523.523.5 | 25.5 | 29.032.032.0 | 36.0 | 4.242.042.0 | 5.1 | 38.021.5 | 46.0 | 23.5 | 25.0 | 42.0 | 18.0 | 30.0 | 38.0 | 58.0 | 3.0 | 3.0 | 5.0 | 7.0 | 1250 | |

| 11 / 40 | 11.5 | 10.2 | 40.0 | 32.0 | 24.0 | 20.523.523.5 | 23.5 | 29.032.032.0 | 32.0 | 4.242.042.0 | 4.2 | 38.021.5 | 42.0 | 21.5 | 25.0 | 25.0 | 18.0 | 18.0 | 38.0 | 38.0 | 3.0 | 3.0 | 5.0 | 5.0 | 700 | |

| 11 / 60 | 11.7 | 9.1 | 60.0 | 12.0 | 26.0 | 20.523.523.5 | 25.5 | 29.032.032.0 | 36.0 | 4.242.042.0 | 5.1 | 38.021.5 | 46.0 | 23.5 | 25.0 | 42.0 | 18.0 | 30.0 | 38.0 | 58.0 | 3.0 | 3.0 | 5.0 | 7.0 | 1500 | |

| 12 / 15 (L) | 12.2 | 9.2 | 15.0 | 5.0 | 24.0 | 20.523.523.5 | 23.5 | 29.032.032.0 | 32.0 | 4.242.042.0 | 4.2 | 38.021.5 | 42.0 | 21.5 | 25.0 | 25.0 | 18.0 | 18.0 | 38.0 | 38.0 | 3.0 | 3.0 | 5.0 | 5.0 | 1400 | |

| 12 / 25 (L) | 11.9 | 8.0 | 25.0 | 5.0 | 24.0 | 1500 | ||||||||||||||||||||

| 12 / 45 (L) | 12.8 | 11.4 | 45.0 | 36.0 | 24.0 | 800 | ||||||||||||||||||||

| 13 / 20 | 13.3 | 8.8 | 20.0 | 4.0 | 26.0 | 20.523.523.523.5 | 25.5 | 29.032.032.032.0 | 36.0 | 4.242.042.04.2 | 5.1 | 38.021.542.0 | 46.0 | 21.5 | 23.5 | 25.025.0 | 42.0 | 18.018.0 | 30.0 | 38.038.0 | 58.0 | 3.03.0 | 3.0 | 5.05.0 | 7.0 | 1300 |

| 13 / 70 (L) | 13.5 | 10.9 | 70.0 | 14.0 | 26.0 | 1750 | ||||||||||||||||||||

| 14 / 8 | 14.0 | 9.8 | 8.0 | 2.0 | 26.0 | x | 20.523.523.523.525.5 | 900 | ||||||||||||||||||

| 14 / 18 (L) | 14.3 | 11.4 | 18.0 | 6.0 | 26.0 | 23.5 | 20.523.523.523.525.5 | 1600 | ||||||||||||||||||

| 14 / 30 (L) | 13.9 | 10.1 | 30.0 | 6.0 | 26.023.5 | 1750 | ||||||||||||||||||||

| 14 / 40 | 14.0 | 10.9 | 40.0 | 5.0 | 26.023.5 | 1800 | ||||||||||||||||||||

| 15 / 20 (L) | 15.2 | 12.5 | 20.0 | 8.0 | 30.0 | 20.523.523.523.525.5 | 29.5 | 29.032.032.032.036.0 | 39.0 | 4.242.042.04.25.1 | 49.0 | 38.021.542.046.0 | 27.0 | 21.523.5 | 1600 | |||||||||||

| 15 / 80 (L) | 15.2 | 12.6 | 80.0 | 16.0 | 30.0 | 2000 | ||||||||||||||||||||

| 16 / 21 (L) | 16.5 | 13.6 | 21.0 | 7.0 | 30.0 | 1800 | ||||||||||||||||||||

| 16 / 25 | 16.0 | 11.5 | 25.0 | 5.0 | 30.0 | 1550 | ||||||||||||||||||||

| 16 / 35 | 15.9 | 12.1 | 35.0 | 7.0 | 30.0 | 2000 | ||||||||||||||||||||

| 16 / 90 (L) | 17.0 | 14.3 | 90.0 | 18.0 | 30.0 | 2250 | ||||||||||||||||||||

| 18 / 16 | 18.0 | 14.3 | 16.0 | 4.0 | 30.0 | x | 20.523.523.523.525.529.5 | 1100 | ||||||||||||||||||

| 18 / 24 (L) | 18.7 | 15.7 | 24.0 | 8.0 | 30.0 | 27 | 20.523.523.523.525.529.5 | 2000 | ||||||||||||||||||

| 18 / 40 (L) | 17.9 | 14.1 | 40.0 | 8.0 | 30.027 | 2250 | ||||||||||||||||||||

| 18 / 100 (L) | 18.8 | 16.2 | 100.0 | 20.0 | 30.027 | 2500 | ||||||||||||||||||||

| 19 / 30 | 18.8 | 14.2 | 30.0 | 6.0 | 30.027 | 1800 | ||||||||||||||||||||

| 20 / 12 | 20.0 | 15.8 | 12.0 | 3.0 | 36.0 | 20.523.523.523.525.529.5 | 35.5 | 29.032.032.032.036.039.0 | 47.0 | 4.242.042.04.25.149.0 | 6.2 | 38.021.542.046.027.0 | 59.0 | x | 25.025.042.0 | 46.0 | 18.018.030.0 | 32.0 | 38.038.058.0 | 64.0 | 3.03.03.0 | 5.0 | 5.05.07.0 | 8.0 | 1200 | |

| 20 / 45 | 20.0 | 16.1 | 45.0 | 9.0 | 36.0 | 33 | 20.523.523.523.525.529.535.5 | 2500 | ||||||||||||||||||

| 21 / 27 | 20.8 | 17.9 | 27.0 | 9.0 | 36.033 | 2200 | ||||||||||||||||||||

| 22 / 20 | 22.0 | 18.3 | 20.0 | 5.0 | x | 20.523.523.523.525.529.535.5 | 2050 | |||||||||||||||||||

| 22 / 50 | 22.0 | 18.1 | 50.0 | 10.0 | 33 | 20.523.523.523.525.529.535.5 | 1400 | |||||||||||||||||||

| 22 / 120 | 22.5 | 19.8 | 120.0 | 24.0 | 33 | 2750 | ||||||||||||||||||||

| 23 / 30 (L) | 23.0 | 20.0 | 30.0 | 10.0 | 33 | 3000 | ||||||||||||||||||||

| 24 / 55 | 24.0 | 20.1 | 55 | 11.0 | 33 | 2800 | ||||||||||||||||||||

| 26 / 24 | 26.0 | 22.3 | 24.0 | 6.0 | 42.0 | 20.523.523.523.525.529.535.5 | 41.5 | 29.032.032.032.036.039.047.0 | 53.0 | 4.242.042.04.25.149.06.2 | 64.0 | 38.021.542.046.027.059.0 | x | 50.0 | 25.025.042.046.0 | 35.0 | 18.018.030.032.0 | 71.0 | 38.038.058.064.0 | 5.0 | 3.03.03.05.0 | 8.0 | 5.05.07.08.0 | 2000 | ||

| 26 / 60 | 26.0 | 22.2 | 60.0 | 12.0 | 42.0 | 39 | 20.523.523.523.525.529.535.541.5 | 3250 | ||||||||||||||||||

| 30 / 28 | 30.0 | 26.5 | 28.0 | 7.0 | 42.0 | x | 20.523.523.523.525.529.535.541.5 | 2000 | ||||||||||||||||||

| 30 / 50 | 29.8 | 25.3 | 50.0 | 10.0 | 42.0 | 39 | 20.523.523.523.525.529.535.541.5 | 2800 | ||||||||||||||||||

| 30 / 70 | 30.0 | 26.2 | 70.0 | 14.0 | 42.039 | 3750 | ||||||||||||||||||||

| 34 / 80 | 34.0 | 30.2 | 80.0 | 16.0 | 50.0 | 20.523.523.523.525.529.535.541.5 | 49.5 | 29.032.032.032.036.039.047.053.0 | 65.0 | 4.242.042.04.25.149.06.264.0 | 9.0 | 38.021.542.046.027.059.0 | 80.0 | 50.0 | x | 25.025.042.046.035.0 | 70.0 | 18.018.030.032.071.0 | 50.0 | 38.038.058.064.05.0 | x | 3.03.03.05.08.0 | 10.0 | 5.05.07.08.0 | 12.0 | 4250 |

| 36 / 200 | 36.0 | 33.4 | 200.0 | 40.0 | 50.0 | 4500 | ||||||||||||||||||||

d0 = Nominal Screw diameter (mm)

d1 = Outer Screw Diamter (mm)

d2 = Screw Root Diameter (mm)

p0 = Nominal Pitch

p = Effective Pitch

g = Number of Starts

LnF = Length of nut body (type SFM)

LnB = Length of nut body (type SBM)

LvF = Length of nut body (Type SFV and SFT)

(L) = Left hand thread available

*Load rate for bronze nut = 1.3 x the value

Now also available in Aluminium. For each screw type we offer a preloaded, anti backlash nut or standard single nut designs, complete with flange for ease of connection.

Special designs of nuts can be supplied via our speedy engineering department.

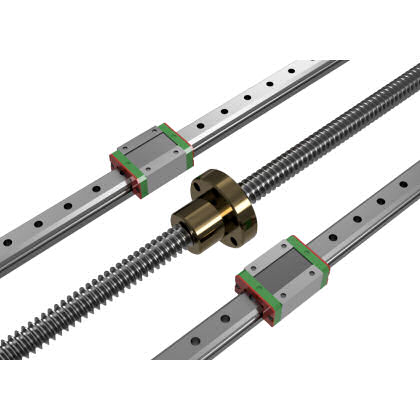

Linear guideways provide excellent load bearing linear motion by re-circulating rolling elements between a profiled rail and a bearing block. By primarily using a four ball path design, within the slide, delivers excellent rigidity and parallelism during operation. The guides can be used in both vertical and horizontal planes.

ABSSAC supplies both radial and thrust bearings, complete with housings, to compliment their expanding lead screw and ball screw ranges. All bearings include the bearing set, bearing housing, snap ring, lock nut, spacer ring and retaining cover. Available to suit all shaft sizes, the range delivers robust radial and thrust protection in any rotary or linear application. Let us help you with your selection.

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details.

ABSSAC welcomes reverse engineering applications. Over the years, many customers have sent damaged leadscrews and nuts for us to measure and replicate, often as a result that dimensional drawings do not exist. Please contact one of our knowledgable sales engineers for further details.