With over 40 years of application experience, our knowledgeable staff are always available. Please contact us on 01386 421 005

We will be more than happy to help, so please call today!

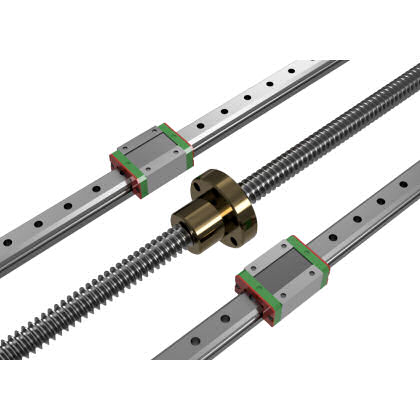

Precision lead screw ranges are available from 1mm to 25mm in diameter and can be combined with an incredibly diverse amount of nut options. Both screws and nuts are available in various materials and performance characteristics and utilizing a variety of machining methods delivers a technical solution that is within budget. Enhancements to the product can be through in-house machining of end journals to the application of dry lubricant technology.

ABSSAC excels in the development of tailored leadscrew and nut solutions for its customers. Set us the challenge !

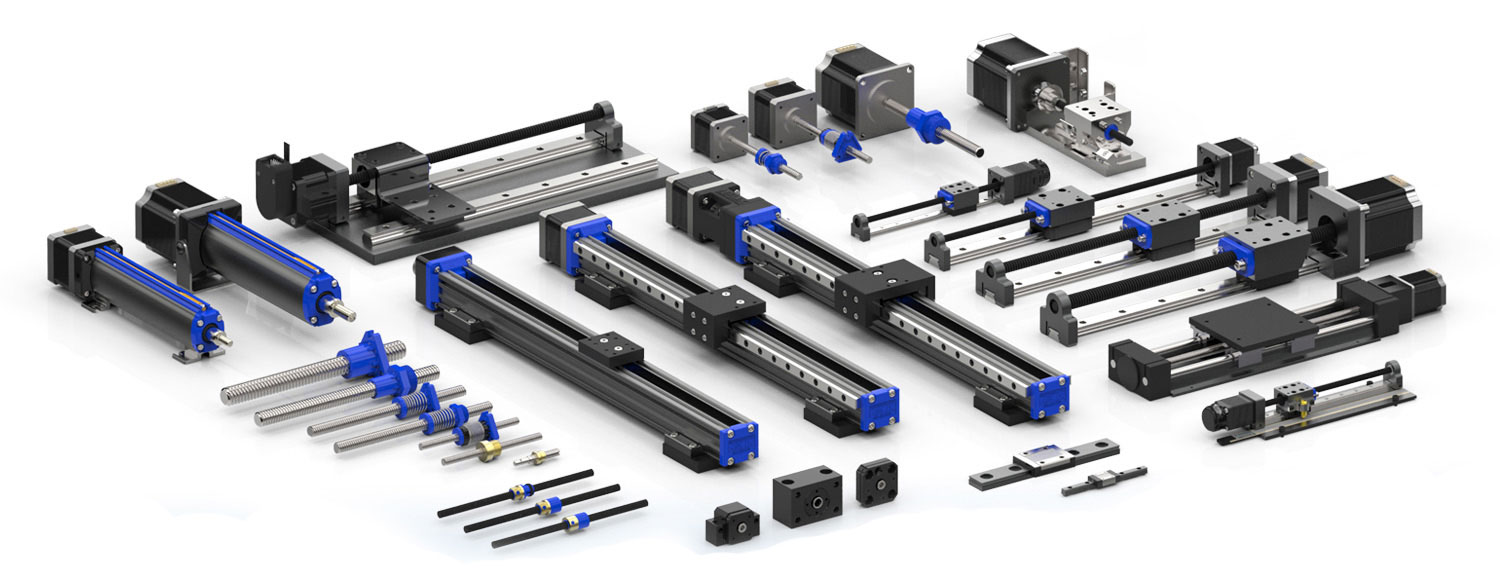

Working closely with our customers to supply a ready to fit machined product not only reduces their scrap rates, but also ensures that the lead screw and nut fit tolerance is maintained every time. With a machining capability that is enjoyed by numerous customers, an excellent journal concentricity product is delivered, regardless of diameter. Working directly from dimensional drawings, or if they do not exist, from physical examples that enable us to reverse engineer from. Combine the lead screw and nuts with a full range of linear guides and rails will provide load support to any linear mechanism. Offering excellent rigidity and parallelism during operation the guides can be used in both vertical and horizontal planes. The whole linear program allows the supply of complete mechanical systems, through knowledge staff.

Our latest machine, the ROMI GL250M, transforms our machining scope and capability. The ROMI GL250M CNC Turning Centre offers a unique integral C axis milling capability. The new machine is part of the long term vision of the company and its progressive UK manufacturing goals.

ROMI GL250M

A2-6” Spindle 65mm Bar Capacity

Fanuc 0i-TF HMI CNC Control with 15” Touchscreen display

C-Axis Milling Capabilities

Servo Driven Tailstock

The package also comes complete with a bespoke external bar support system for longer length screw stocks.

There are 3 basic ways to make the lead screw thread, those being, rolling, whirling and grinding. Each method has its advantages and disadvantages so let’s look at each method individually.

Lead screws can be found in many industries including Automation, Medical, Defence and Transport applications to name a few.

The thread form is squeezed into the bar of material using dies under high force. This method makes a thread with a really good sliding surface finish and the process is quick. As the rolling process compresses the material it also superficially hardens the working area of the thread.

The majority of our threads are rolled. The disadvantage to a rolled thread is at that very high precision isn’t possible. Most rolled threads are 2G, with care we can roll most sizes to 3G but 4G is too much for rolling.

The thread is machined rather than formed as it is in rolling. This means the thread is high accuracy but doesn’t have great surface finish nor is it hardened. This thread (with natural finish i.e. uncoated) is not suitable for use of plastic nuts due to surface finish.

Very precise thread can be created in hardened materials but you have limited choice of sizes and thread forms. The process is also labour intensive which makes them a higher price and longer delivery time than the other methods. A ground thread is normally used where accuracy is of upmost importance.

As standard, most rolled lead screws are made from 300 series Stainless Steel. These materials form well, give a great surface finish and have good corrosion resistance. For a ground screw, something like 440C or 17-4pH works well as it is a grade of stainless which can achieve sufficient hardness. But these types of Stainless doesn’t have the corrosion resistance of 300 series. Customers like the thought of 440C or 17-4pH because of its hardness but unless it’s a ground thread, it is difficult to machine and doesn’t leave a great surface finish.

Several types of material can be used for the lead screw nut. The material you choose for the nut depends on the application. Broadly speaking, you have 3 nut materials; Steel, Copper Alloy or Polymer (Plastic)

Used for high loads at low speed.

Bronze nuts are very popular for lead screws. There is a vast choice of bronzes to choose from, such as Leaded (Pb) Bronze, SAE660 or Sigma 7 Bronze are also popular choices. (The Pb in the material reduces the sliding friction between nut and screw).

Materials with higher strength include Tin Bronzes (PB102) and Alu Bronzes (CA104) but these have more friction than the Pb Bronze, less tolerant of lack of alignment, lubrication and shock loads.

The number of plastics suitable to make lead screw nuts is almost endless however, there are several that have become the industry norm.

Plastics are useful because in the main they are low friction and require little if any lubrication.

Various coatings can be applied to the screw to reduce friction of the mating part. PTFE based coatings can have very low coefficient of friction but can be quite soft and can be rubbed off by abrasion of even a plastic nut with bronze nuts wearing through it quickly.

Working closely with our customers to supply a finished ready to fit linear product, not only reduces their scrap rates, but also ensures that the lead screw and nut fit tolerances are maintained every time. Holding excellent journal concentricity, regardless of diameter, the manufacturing services deliver complete turn-key lead screw assemblies to specification

Linear guideways provide excellent load bearing linear motion by re-circulating rolling elements between a profiled rail and a bearing block. By primarily using a four ball path design, within the slide, delivers excellent rigidity and parallelism during operation. The guides can be used in both vertical and horizontal planes.

ABSSAC supplies both radial and thrust bearings, complete with housings, to compliment their expanding lead screw and ball screw ranges. All bearings include the bearing set, bearing housing, snap ring, lock nut, spacer ring and retaining cover. Available to suit all shaft sizes, the range delivers robust radial and thrust protection in any rotary or linear application. Let us help you with your selection.

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details.

ABSSAC welcomes reverse engineering applications. Over the years, many customers have sent damaged leadscrews and nuts for us to measure and replicate, often as a result that dimensional drawings do not exist. Please contact one of our knowledgable sales engineers for further details.

Thread Forms: Acme, Trapezoidal, High-Helix, Modified Acme, Buttress, Ball Screw

Nut Materials: Bronze, Acetal, Delrin, PEEK, Ultem, Vespel, Torlon and many more.

With well over 3 decades of application experience and knowledgeable staff that are always available, please call today!