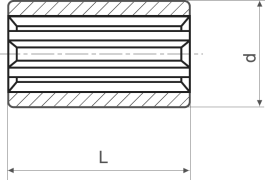

Machined from high grade EN8 steel in diameters of 14mm to 54mm as standard and supplied in lengths up to 3 metres enables us to supply into the most high load and long life expectancy linear applications.

Abssac has recently supplied one of the largest splined shafts to date. Measuring a massive 150mm in diameter, with 8 splines along its 2 metres length and weighing in at 250kg !. Manufactured from EN24T steel the customer did not have any technical drawings from which we could quote from. The only information available was to be gathered from the broken and distorted sample sent to us after a catastrophic failure at the paper mill. Abssac was successful in being able to replicate the part and deliver the new part ready to fit into the repaired machine.

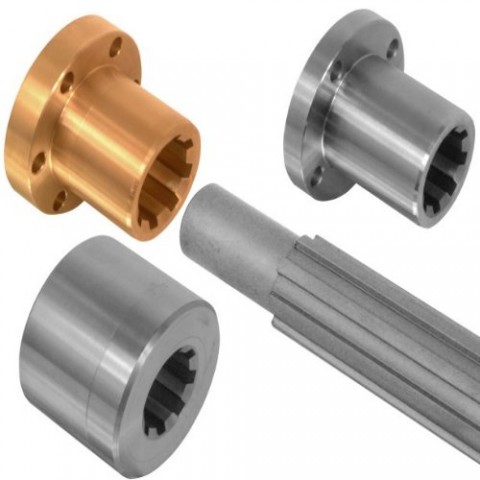

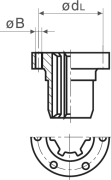

As standard splined shaft are available from 14mm to 54mm in diameter with either 6 or 8 spline formats. A full range of flanged steel or bronze sleeves are available to compliment the splines. Standard lengths of 250,500,1000,2000 and 3000mm are available from stock. The splined shafts can also be complimented by a range of matched phosphor bronze flange nuts’ which are supplied complete with PCD arranged attachment holes.

The product has a keen market price, fast delivery and ISO9001 assurance to give the product a competitive edge. Call us for a competitive quotation on 01386 421005

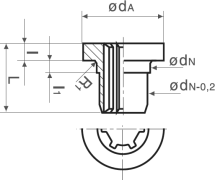

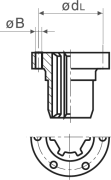

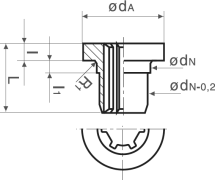

a*: Number of Keys

a*: Number of Keys

a*: Number of Keys

a*: Number of Keys

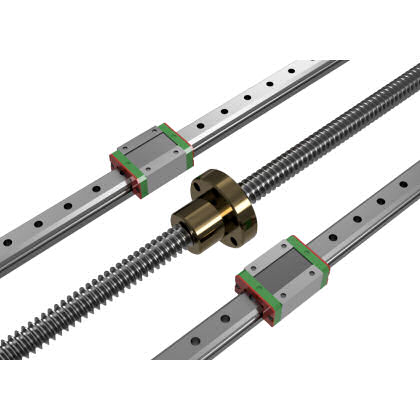

Linear guideways provide excellent load bearing linear motion by re-circulating rolling elements between a profiled rail and a bearing block. By primarily using a four ball path design, within the slide, delivers excellent rigidity and parallelism during operation. The guides can be used in both vertical and horizontal planes.

ABSSAC supplies both radial and thrust bearings, complete with housings, to compliment their expanding lead screw and ball screw ranges. All bearings include the bearing set, bearing housing, snap ring, lock nut, spacer ring and retaining cover. Available to suit all shaft sizes, the range delivers robust radial and thrust protection in any rotary or linear application. Let us help you with your selection.

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details.

ABSSAC welcomes reverse engineering applications. Over the years, many customers have sent damaged leadscrews and nuts for us to measure and replicate, often as a result that dimensional drawings do not exist. Please contact one of our knowledgable sales engineers for further details.