The name TB Wood’s Sure-Flex® Product has long been associated with quality. TB Wood’sSure-Flex® couplings utilises a rubber (EPDM), Neoprene, or Hytrel sleeve between two cast hubs. The flexible element allows 4-way flexing action and absorbs virtually all types of shock, misalignment, and end float. The sleeves also exhibit exceptional torsional flexibility. The cast hubs can be supplied bored and keyed to suit motor shafts from 10mm to 140mm as standard . With Sure-Flex® couplings, the need for lubrication and maintenance is eliminated. As a result, these couplings provide clean, dependable, and quiet performance for a variety of applications.

Sure-Flex® shaft couplings can be installed quickly and easily because there are no bolts, gaskets, covers or seals. Alignment can be checked with a straight edge placed across the outside of the precision machined flanges. No special tools are needed for installation, alignment or removal. With Sure-Flex couplings, the need for lubrication and maintenance is also eliminated. The uniquely designed connecting teeth allow lateral flexibility whilst accepting both parallel and angular misalignment without wear.As a result, these couplings provide clean, dependable, and quiet performance for a variety of applications.

If you require further technical information, please do not hesitate to contact our sales engineers who will be more than happy to help you with your selection.

| Sleeve Material | EPDM | NEOPRENE | HYTREL | URETHANE | |||

|---|---|---|---|---|---|---|---|

| Available Sleeve Styles | Style designator | ||||||

| 1 pc, unsplit | JE | JN | H | U | |||

| 1 pc, split | JES | JNS | - | - | |||

| 2 piece | E | N | HS | - | |||

| Typical Use | General Purpose | Oil Resist Non-flame | General Purpose | Stiffness | |||

| Torsional wind up | 15° | 15° | 7° | 3° | |||

| Angular Misalignment | 1° | 1° | 1/4° | 1/4° | |||

| Temperature (C°) | |||||||

| Maximum | +135° | +94° | +122° | +94° | |||

| Minimum | -34° | -17° | -54° | -63° | |||

| Product No. | Product Description |

|---|---|

| 3J | 3JE EPDM |

| 4J | 4JE EPDM |

| 5J | 5JE EPDM |

| 6J | 6JE EPDM |

| 7J | 7JE EPDM |

| 8J | 8JE EPDM |

| 9J | 9JE EPDM |

| 10J | 10JE EPDM |

| 3JS | 3JES EPDM Split |

| 4JS | 4JES EPDM Split |

| 5JS | 5JES EPDM Split |

| 6JS | 6JES EPDM Split |

| 7JS | 7JES EPDM Split |

| 8JS | 8JES EPDM Split |

| 9JS | 9JES EPDM Split |

| 10JS | 10JES EPDM Split |

| 3JN | 3JN Neoprene |

| 4JN | 4JN Neoprene |

| 5JN | 5JN Neoprene |

| 6JN | 6JN Neoprene |

| 7JN | 7JN Neoprene |

| 8JN | 8JN Neoprene |

| 3JNS | 3JNS Neoprene Split |

| 4JNS | 4JNS Neoprene Split |

| 5JNS | 5JNS Neoprene Split |

| 6JNS | 6JNS Neoprene Split |

| 7JNS | 7JNS Neoprene Split |

| 8JNS | 8JNS Neoprene Split |

| Product No. | Product Description |

|---|---|

| 4 | 4E EPDM |

| 5 | 5E EPDM |

| 6 | 6E EPDM |

| 7 | 7E EPDM |

| 8 | 8E EPDM |

| 9 | 9E EPDM |

| 10 | 10E EPDM |

| 11 | 11E EPDM |

| 12 | 12E EPDM |

| 13 | 13E EPDM |

| 14 | 14E EPDM |

| 16 | 16E EPDM |

| 4N | 4N Neoprene |

| 5N | 5N Neoprene |

| 6N | 6N Neoprene |

| 7N | 7N Neoprene |

| 8N | 8N Neoprene |

| 9N | 9N Neoprene |

| 10N | 10N Neoprene |

| 11N | 11N Neoprene |

| 12N | 12N Neoprene |

| 13N | 13N Neoprene |

| 14N | 14N Neoprene |

| Product No. | Product Description |

|---|---|

| 6H | 6H Hytrel |

| 7H | 7H Hytrel |

| 8H | 8H Hytrel |

| 9H | 9H Hytrel |

| 10H | 10H Hytrel |

| 11H | 11H Hytrel |

| 12H | 12H Hytrel |

| 6HS | 6HS Split Hytrel |

| 7HS | 7HS Split Hytrel |

| 8HS | 8HS Split Hytrel |

| 9HS | 9HS Split Hytrel |

| 10HS | 10HS Split Hytrel |

| 11HS | 11HS Split Hytrel |

| 12HS | 12HS Split Hytrel |

| 13HS | 13HS Split Hytrel |

| 14HS | 14HS Split Hytrel |

| 10U | 10U Urethane |

| 11U | 11U Urethane |

| 12U | 12U Urethane |

| Size | EPDM Sleeves | Neoprene Sleeves | KW @ RPM | Torque (Nm) | Stiffness (Nm/rad) | Max RPM | |||

|---|---|---|---|---|---|---|---|---|---|

| 100 | 970 | 1450 | 3000 | ||||||

| 3 | JE,JES | JN,JNS | 0.07 | 0.69 | 1.03 | 2.13 | 6.8 | 26 | 9200 |

| 4 | E,JE,JES | N,JN,JNS | 0.14 | 1.38 | 2.06 | 4.26 | 13.6 | 52 | 7600 |

| 5 | E,JE,JES | N,JN,JNS | 0.28 | 2.75 | 4.12 | 8.52 | 27.1 | 104 | 7600 |

| 6 | E,JE,JES | N,JN,JNS | 0.53 | 5.16 | 7.72 | 15.97 | 50.8 | 194 | 6000 |

| 7 | E,JE,JES | N,JN,JNS | 0.86 | 8.32 | 12.44 | 25.73 | 82.0 | 313 | 5250 |

| 8 | E,JE,JES | N,JN,JNS | 1.34 | 13.03 | 19.47 | 40.29 | 128.2 | 490 | 4500 |

| 9 | E,JE,JES | N | 2.13 | 20.66 | 30.88 | 63.89 | 203.4 | 777 | 3750 |

| 10 | E,JE,JES | N | 3.40 | 33.00 | 49.32 | 102.05 | 324.8 | 1241 | 3600 |

| 11 | E | N | 5.36 | 51.99 | 77.72 | 160.79 | 511.8 | 1955 | 3600 |

| 12 | E | N | 8.52 | 82.63 | 123.52 | 255.57 | 813.5 | 3107 | 2800 |

| 13 | E | N | 13.43 | 130.26 | 194.72 | 402.87 | 1282.4 | 4898 | 2400 |

| 14 | E | N | 21.30 | 206.58 | 308.81 | 638.92 | 2033.7 | 7768 | 2200 |

| 16 | E | 55.91 | 542.28 | 810.63 | 1677.16 | 5338.5 | 20392 | 1500 | |

| Size | Hytrel Sleeves | Urethane Sleeves | KW @ RPM | Torque (Nm) | Stiffness (Nm/rad) | Max RPM | |||

|---|---|---|---|---|---|---|---|---|---|

| 100 | 970 | 1450 | 3000 | ||||||

| 6 | H,HS | 2.13 | 20.66 | 30.88 | 63.89 | 203.4 | 1130 | 6000 | |

| 7 | H,HS | 3.40 | 33.00 | 49.32 | 102.05 | 324.8 | 2260 | 5250 | |

| 8 | H,HS | 5.36 | 51.99 | 77.72 | 160.79 | 511.8 | 3390 | 4500 | |

| 9 | H,HS | 8.52 | 82.63 | 123.52 | 255.57 | 813.5 | 5367 | 3750 | |

| 10 | H,HS | U | 13.43 | 130.26 | 194.72 | 402.87 | 1282.4 | 11299* | 3600 |

| 11 | H,HS | U | 21.30 | 206.58 | 308.81 | 638.92 | 2033.7 | 14123* | 3600 |

| 12 | H,HS | U | 37.27 | 361.52 | 540.42 | 1118.11 | 3559.0 | 25422* | 2800 |

| 13 | HS | 55.93 | 542.49 | 810.94 | 1677.80 | 5340.6 | 41680 | 2400 | |

| 14 | HS | 85.76 | 831.84 | 1243.48 | 2572.71 | 8189.1 | 67028 | 2200 | |

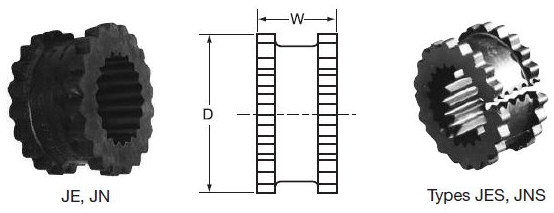

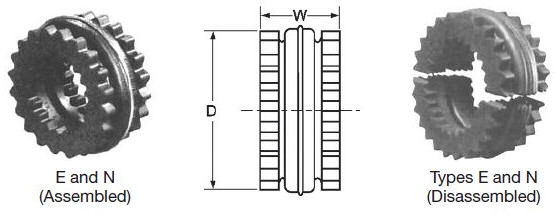

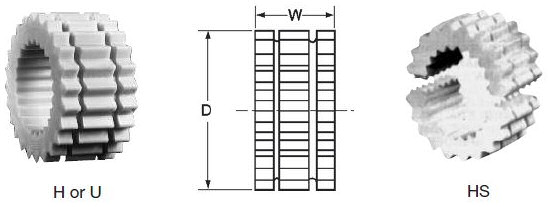

Flexible sleeves for Sure-Flex couplings are available in four materials (EPDM, Neoprene, Hytrel and Urethane) and in three basic constructions. The various types are shown and described here.

JE-JES-JN-JNS

JE-JES-JN-JNSJ sleeves are molded EPDM rubber (E) or Neoprene (N). They are available in one-piece solid construction (JE, JN) or one-piece split construction (JES, JNS). These sleeves may be used in any Sure-Flex flange within a given size.

E-N

E-NThese sleeves are of two-piece design with a retaining ring. They are available in either EPDM (E) or Neoprene (N). They may be used with any flange within a given size. Sleeves are shown here assembled and disassembled.

H-HS-U

H-HS-UH (Hytrel) and U (Urethane) sleeves designed for high-torque applications, transmit four times as much power as an equivalent EPDM or Neoprene sleeve. Available in one-piece solid construction (H or U) or two-piece split construction (HS), these can be used only with S, C, and SC flanges. They cannot be used with J or B flanges or as direct replacements for EPDM or Neoprene sleeves.

A full range of hubs and flanges are available to suit all the sleeves. All details can be found on the on line catalogue or call our knowledgeable sales team to help with your specification on 01386 421005.

Type SC Spacer component hub

Type J flanges sizes 3 4 and 5 are manufactured of sintered carbon steel

Type B flanges for use with Wood's Sure-Grip Bushings

Type C Clamp Hub flanges

Type S flanges sizes 6 through 16 are manufactured of high strengthcast iron