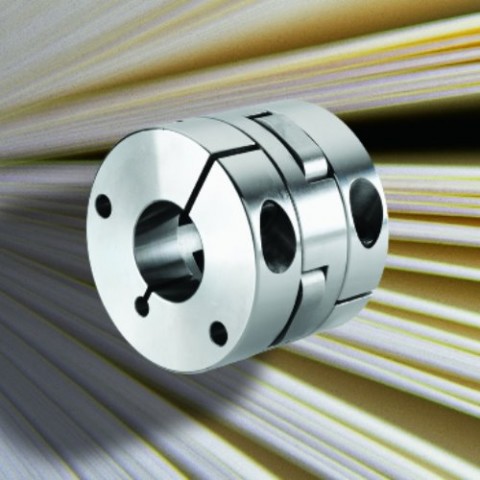

The compact precision coupling with high performance. Semiflex® is a torsionally stiff, precision coupling that is without radial restoring forces. Apart from compensating for axial and angular misalignment, the coupling offers high radial misalignment capacity in conjunction with a compact design. The torsionally stiff coupling compensates for misalignment without restoring forces by means of a unique system of two pairs of parallel links arranged at 90° to each other. The angular synchronisation of the connected shafts always remains constant regardless of the misalignment. Examples of use for the precision all-metal couplings are in printing machines, packaging machines and in material-handling equipment.

There are three models

Standard F series - A symbiosis of performance, compact design and generous misalignment capacity. Torque (TKN) 44 Nm to 7,040 Nm. Bore diameter up to 120 mm.

Compact Plus C series - Ideal for limited space. Torque (TKN) 69 Nm to 7,040 Nm. Bore diameter up to 100 mm.

Dynamic D series - The light-weight Aluminium series. Torque (TKN) 40 Nm to 180 Nm. Bore diameter up to 35 mm.

Semiflex is a torsionally-stiff, precise shaft coupling for transmitting torque from one shaft to another, in those cases where shaft alignment can not be guaranteed due to manufacturing tolerances, assembly procedures, wear, or operational specifics. All types of shaft misalignment are accommodated via the proven Semiflex design. The angular velocity of the connected shafts remains totally synchronised, regardless of the shaft misalignment. No restoring forces are induced.

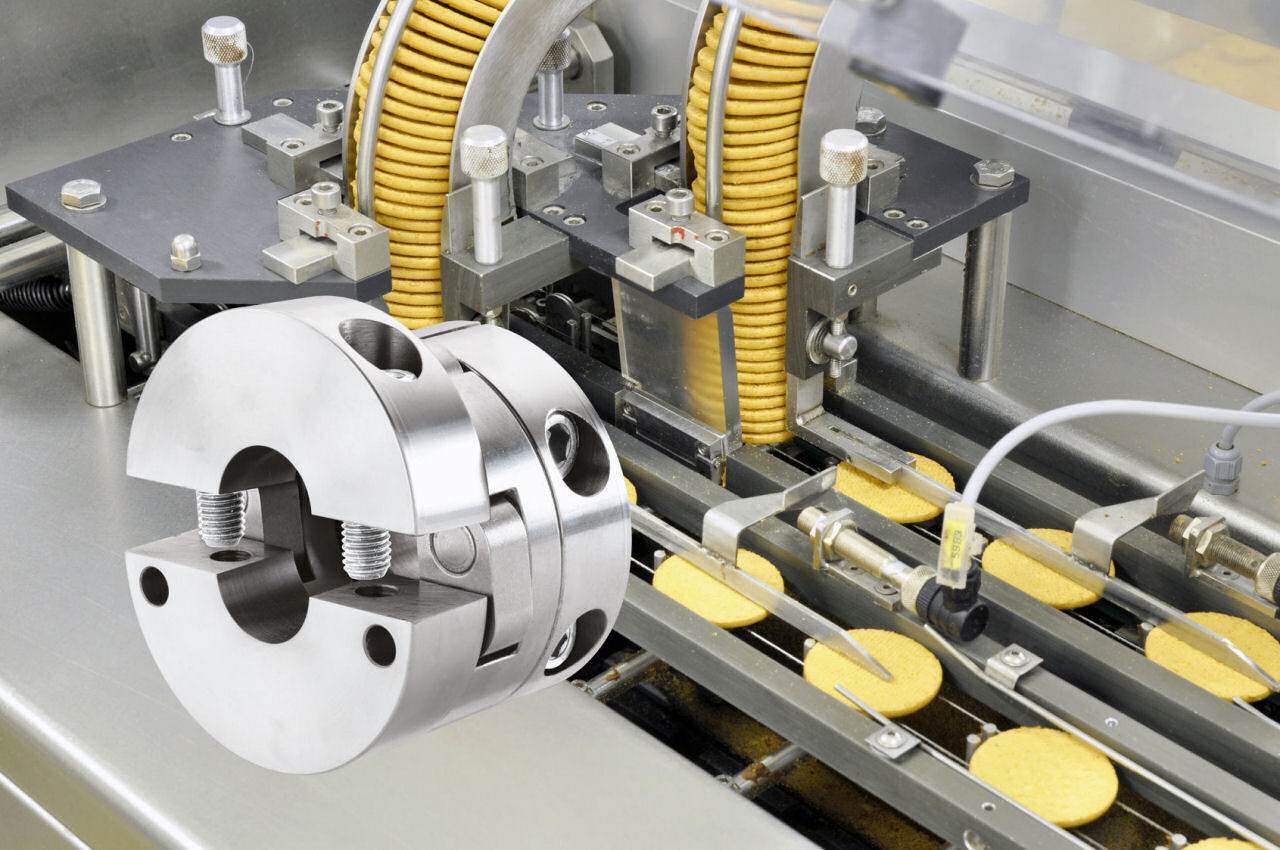

It is also worth mentioning that shaft couplings used within determined industries sometime call for customised materials to be compliant with special regulations and requirements. Examples of this include packaging machines for the food and pharmaceutical industries well as coating machinery under vacuum conditions. In such industries, the choice of high grade steel is adapted to the respective customer requirements. Many industries require the use of Stainless steel and the Schmidt-Kupplung product portfolio can meet this challenge across the majority of its product range. Precision, high displacement and compact design. For example, within the food-processing industry it is common to see shaft couplings being utilised in many areas of the driven part of the machine. The working axial area available for installation can often be very minimal. There can also be the case where the driven shaft coupling comes into direct contact with the food substrate. Mechanically, the shaft coupling must deliver reliable precision torque transmission, high torsional stiffness, axial shaft displacement and ease of fitting, these are typical application demands.

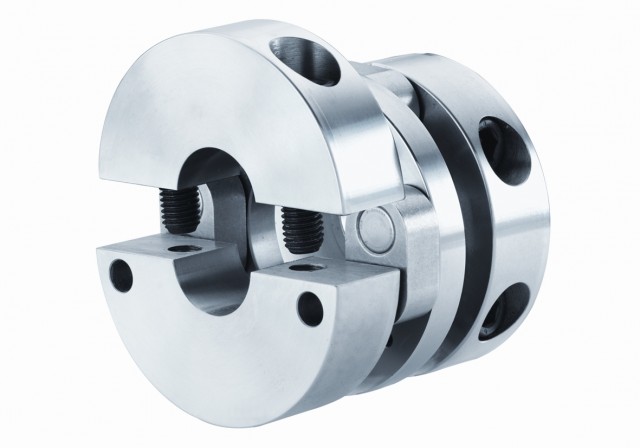

In this scenario the Schmidt-Kupplung range can offer a stainless steel solution called the Semiflex Compact Plus Type C320 with split clamp hubs. By using a split clamp hub solution there is no need to axially shift any bordering components of the machine during installation. Additionally, the specific hygiene requirements can be met by using a high grade 1.4301 stainless steel for its construction.

In this scenario the Schmidt-Kupplung range can offer a stainless steel solution called the Semiflex Compact Plus Type C320 with split clamp hubs. By using a split clamp hub solution there is no need to axially shift any bordering components of the machine during installation. Additionally, the specific hygiene requirements can be met by using a high grade 1.4301 stainless steel for its construction.

The torsionally stiff coupling, with an outer diameter of 120 mm, has a nominal torque of 316 Nm (maximum torque 330 Nm) and a radial displacement capacity of 3 mm, according to torque and displacement requirements. What makes the shaft coupling unique is the transmission of the rotary motion and torque takes place in the coupling through two pairs of parallel links arranged at 90° to each other. They connect the driving side and the power take-off with the centre disc. The lateral displacement compensation takes place through a swivelling movement of the needle bearing parallel link rods on the connecting bolts that are located in the internal discs.

Innovatively, synchronisation between driver and driven ends is therefore guaranteed despite the high displacement. Installation of the coupling, which is already designed to be very compact, is made easy with an overall length of only 88 mm.

To meet the stringent regulations for machines that come into contact with food fit for human consumption, the needle bearings are equipped with food-grade grease. In other cases food legislation compliant slide bearings can be used. Similar coupling solutions are also applicable to packaging machines for the pharmaceutical sector and bottling plants. To some extent it was these industries that pioneered the use of 1.4501 stainless steel. Likewise other Schmidt couplings or indeed coupling components such as coupling links are made out of 1.4541 and 1.4571 premium steel.

Some other Typical applications are:

The unique function system of the coupling compensates for misalignment without deformation and thus without restoring forces.

The coupling is characterised by a compact overall axial length that allows the user to realise a space-saving design.

In series production, Semiflex offers a radial misalignment capacity of up to 6.6 mm. Misalignment values up to 20 mm are realised for specific application requirements.

The compact coupling has a high torsional stiffness and has a performance-orientated design for high torque transmission.

We welcome the opportunity to adapt the standard design and optimise it for specific applications. Example:

The module design system allows the free combination of 6 different shaft mountings.