The main difference between the ActiveCAM design and traditional compression spring assemblies is the way that they work. A conventional compression spring assembly forces the threads of the nut portions against the screw threads, thereby splitting the nuts apart to eliminate backlash. The ActiveCAM design uses a rigid stainless steel spacer, which looks like a sleeve, and performs the biasing. The biasing is produced by an internal torsion spring that rotates the sleeve. On the end of the sleeve there is a cam, which rotates and self-compensates for wear, or for play between members and the shaft. One of the main features of the ActiveCAM plastic nut assembly is the ability to be dropped into any application where precise motion and rigid strength is needed with loads up to 114 Kg, yet costs less than half the price of a traditional ballscrew. Inherent compounds that make up the plastic used in the design, means that these assemblies do not need to be lubricated making them ideal for applications with clean or arduous environments.

Material: Bearing grade Acetal

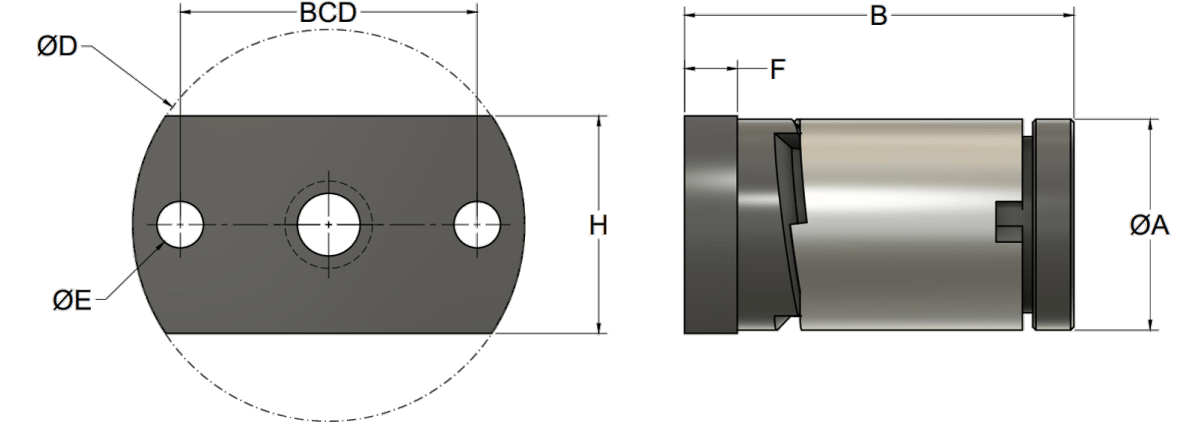

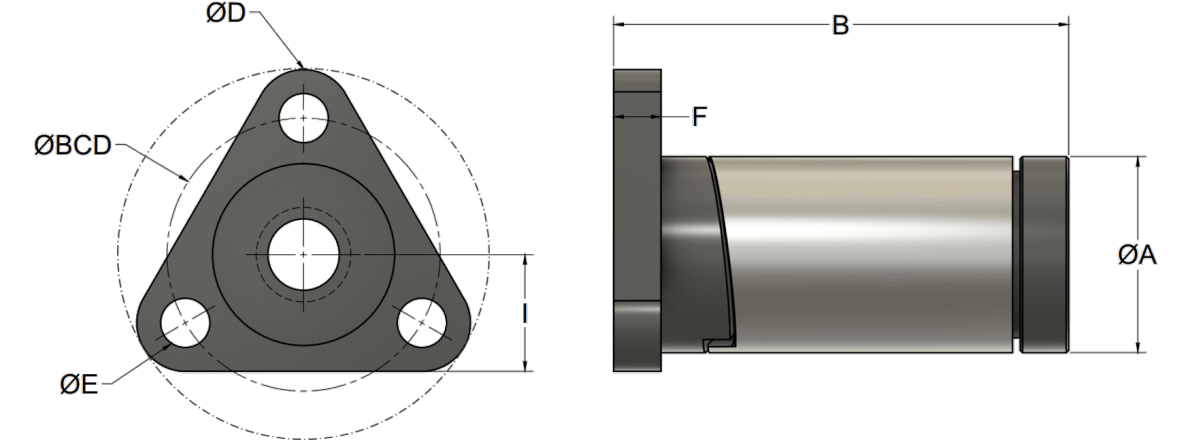

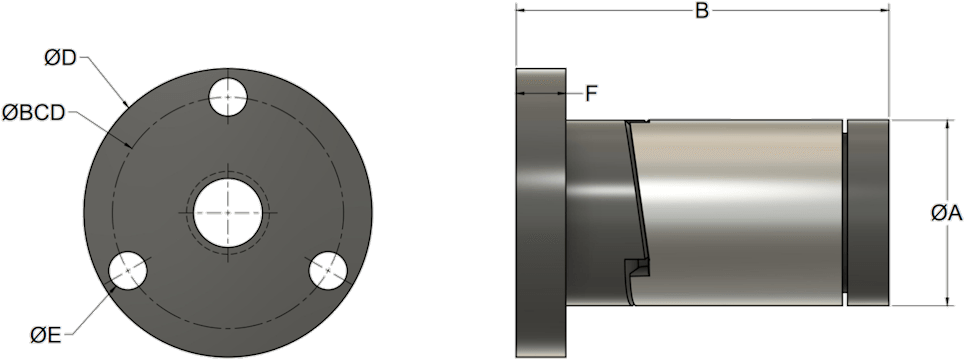

| Part No. | Max Dynamic Load (N) | Dia. (mm) | Lead (mm) | Dimensions | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A (mm) | B (mm) | D (mm) | E (mm) | F (mm) | H (mm) | I (mm) | BCD (mm) | |||||||||||||||

| Type A | XCF6X1M | 44 | 6 | 1 | 16.3 | 30 | 30.2 | 3.6 | 4.1 | 16.8 | x | 22.9 | ||||||||||

| Type A | XCF4-6X1.5M | 6 | ||||||||||||||||||||

| Type A | XCF8-6X1.5M | 12 | ||||||||||||||||||||

| Type B | XCF8X2M | 44 | 111 | 6 | 8 | 2 | 16.3 | 20.6 | 30 | 47.6 | 30.2 | 38.9 | 3.6 | 5 | 4.1 | 5.1 | 16.8 | x | x | 12.2 | 22.9 | 28.6 |

| Type B | XCF2-8X2M | 4 | ||||||||||||||||||||

| Type B | XCF4-8X2M | 8 | ||||||||||||||||||||

| Type B | XCF6-8X2M | 12 | ||||||||||||||||||||

| Type B | XCF10-8X2M | 20 | ||||||||||||||||||||

| Type B | XCF10X2M (L) | 10 | 44111 | 2 | ||||||||||||||||||

| Type B | XCF10X3M (L) | 10 | 3 | |||||||||||||||||||

| Type B | XCF2-10X2M | 10 | 4 | |||||||||||||||||||

| Type B | XCF2-10X2.5M | 10 | 5 | |||||||||||||||||||

| Type B | XCF4-10X1.5M | 10 | 6 | |||||||||||||||||||

| Type B | XCF5-10X2M | 10 | 10 | |||||||||||||||||||

| Type B | XCF5-10X2.4M | 10 | 12 | |||||||||||||||||||

| Type B | XCF6-10X3.3M | 10 | 20 | |||||||||||||||||||

| Type C | XCF12X2MV | 44111 | 556 | 68 | 12 | 2 | 16.320.6 | 28.5 | 3047.6 | 57.2 | 30.238.9 | 44.5 | 3.65 | 5.1 | 4.15.1 | 7.6 | 16.8x | x | x12.2 | 35.7 | ||

| Type C | XCF12X3M | 3 | ||||||||||||||||||||

| Type C | XCF2-12X2M | 4 | ||||||||||||||||||||

| Type C | XCF2-12X2.5M | 5 | ||||||||||||||||||||

| Type C | XCF3-12X2M | 6 | ||||||||||||||||||||

| Type C | XCF4-12X2.5M | 10 | ||||||||||||||||||||

| Type C | XCF6-12X2.5M | 15 | ||||||||||||||||||||

| Type C | XCF8-12X2M | 16 | ||||||||||||||||||||

| Type C | XCF10-12X2.5M | 25 | ||||||||||||||||||||

| Type C | XCF16X4M (L) | 778 | 44111556 | 16 | 6812 | 4 | 35.6 | 16.320.628.5 | 66 | 3047.657.2 | 54.1 | 30.238.944.5 | 5.6 | 3.655.1 | 12.7 | 4.15.17.6 | 42.9 | |||||

| Type C | XCF2-16X2.5M | 778 | 5 | |||||||||||||||||||

| Type C | XCF4-16X2M | 778 | 8 | |||||||||||||||||||

| Type C | XCF7-16X2.3M | 778 | 16 | |||||||||||||||||||

| Type C | XCF5-16X5M | 778 | 25 | |||||||||||||||||||

| Type C | XCF7-16X5M | 778 | 35 | |||||||||||||||||||

(L) = Left hand thread available