This cold rolled formed lead screw material has a smooth finish for reduced friction and a strong grain structure for driving high loads. As standard the maximum length of screw as is 144inch (365mm) on this imperially sized product. (Diameter 1.0inch)

Standard Features:

Precision rolled ACME threads have a 2G thread fit. The lead error over the length of the screw is 0.006" maximum per foot.

| Screws | Available Nuts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Name (inch) | Thread Diameter (inch) | Threads per Inch | Thread Starts | Thread Type | Thread Lead (inch) |  | .jpg) |  |  | .jpg) |  |  |  | |

| Matching AB Nut | Matching ABF Nut | Matching ABFT Nut | Matching SN Nut | Matching SNF Nut | Round Flange | Rectangle Flange | Large Triangle Flange | Small Triangle Flange | ||||||

| 1/4-16-1 | 1/4INCH | 16 | 1 | acme | 0.0625 | • | • | • | • | • | • | |||

| 1/4-16-2 | 1/4INCH | 16 | 2 | acme | 0.125 | • | • | • | • | • | • | |||

| 1/4-16-4 | 1/4INCH | 16 | 4 | acme | 0.25 | • | • | • | • | • | • | |||

| 1/4-20-1 | 1/4INCH | 20 | 1 | acme | 0.05 | • | • | • | • | • | • | |||

| 5/16-8-2 | 5/16INCH | 8 | 2 | stub acme | 0.25 | • | • | • | ||||||

| 5/16-8-4 | 5/16INCH | 8 | 4 | stub acme | 0.5 | • | • | • | ||||||

| 3/8-10-1 | 3/8 INCH | 10 | 1 | acme | 0.1 | • | • | • | • | • | ||||

| 3/8-10-2 | 3/8 INCH | 10 | 2 | acme | 0.2 | • | • | • | • | • | ||||

| 3/8-12-1 | 3/8 INCH | 12 | 1 | acme | 0.0833 | • | • | • | • | • | ||||

| 3/8-12-2 | 3/8 INCH | 12 | 2 | acme | 0.1667 | • | • | • | • | • | ||||

| 3/8-16-1 | 3/8 INCH | 16 | 1 | acme | 0.0625 | • | • | • | • | • | ||||

| 3/8-20-1 | 3/8 INCH | 20 | 1 | acme | 0.05 | • | • | • | • | • | ||||

| 3/8-4-5 | 3/8 INCH | 4 | 5 | stub acme | 1.25 | • | • | • | • | • | ||||

| 3/8-5-5 | 3/8 INCH | 5 | 5 | stub acme | 1 | • | • | • | • | • | ||||

| 3/8-8-1 | 3/8 INCH | 8 | 1 | stub acme | 0.125 | • | • | • | • | • | ||||

| 3/8-8-2 | 3/8 INCH | 8 | 2 | stub acme | 0.25 | • | • | • | • | • | ||||

| 3/8-8-3 | 3/8 INCH | 8 | 3 | stub acme | 0.375 | • | • | • | • | • | ||||

| 3/8-8-4 | 3/8 INCH | 8 | 4 | stub acme | 0.5 | • | • | • | • | • | ||||

| 7/16-8-2 | 7/16INCH | 8 | 2 | stub acme | 0.25 | • | • | • | • | • | ||||

| 7/16-8-4 | 7/16INCH | 8 | 4 | stub acme | 0.5 | • | • | • | • | • | ||||

| 1/2-10-1 | 1/2INCH | 10 | 1 | acme | 0.1 | • | • | • | • | |||||

| 1/2-10-2 | 1/2INCH | 10 | 2 | acme | 0.2 | • | • | • | • | |||||

| 5/8-10-1 | 5/8INCH | 10 | 1 | acme | 0.1 | • | • | • | • | |||||

| 5/8-10-2 | 5/8INCH | 10 | 2 | acme | 0.2 | • | • | • | • | |||||

| 5/8-8-1 | 5/8INCH | 8 | 1 | stub acme | 0.125 | • | • | • | • | |||||

| 5/8-8-2 | 5/8INCH | 8 | 2 | stub acme | 0.25 | • | • | • | • | |||||

| 5/8-8-4 | 5/8INCH | 8 | 4 | stub acme | 0.5 | • | • | • | • | |||||

| 3/4-10-1 | 3/4INCH | 10 | 1 | acme | 0.1 | • | • | • | • | |||||

| 3/4-8-1 | 3/4INCH | 8 | 1 | acme | 0.125 | • | • | • | • | |||||

| 3/4-6-1 | 3/4INCH | 6 | 1 | acme | 0.167 | • | • | • | • | |||||

| 3/4-5-1 | 3/4INCH | 5 | 1 | acme | 0.2 | • | • | • | • | |||||

| 3/4-10-5 | 3/4INCH | 10 | 5 | acme | 0.5 | • | • | • | • | |||||

| 3/4-8-8 | 3/4INCH | 8 | 8 | acme | 1 | • | • | • | • | |||||

| 3/4-5-10 | 3/4INCH | 5 | 10 | acme | 2 | • | • | • | • | |||||

| 1.0-10-1 | 1.0 INCH | 10 | 1 | acme | 0.1 | • | • | • | ||||||

| 1.0-8-1 | 1.0 INCH | 8 | 1 | acme | 0.125 | • | • | • | ||||||

| 1.0-5-1 | 1.0 INCH | 5 | 1 | acme | 0.2 | • | • | • | ||||||

| 1.0-4-1 | 1.0 INCH | 4 | 1 | acme | 0.25 | • | • | • | ||||||

| 1.0-10-5 | 1.0 INCH | 10 | 5 | ACME | 0.5 | • | • | • | ||||||

| 1.0-10-10 | 1.0 INCH | 10 | 10 | ACME | 1 | • | • | • | ||||||

If you are interested in the using the acme screw ranges, do not forget that we also supply the full range of linear guides and rails which can provide the load support in your linear mechanism. Offering excellent rigidity and parallelism during operation the guides can be used in both vertical and horizontal planes.

If you are interested in the using the acme screw ranges, do not forget that we also supply the full range of linear guides and rails which can provide the load support in your linear mechanism. Offering excellent rigidity and parallelism during operation the guides can be used in both vertical and horizontal planes.

Following the link to that product page Guides

.jpg)

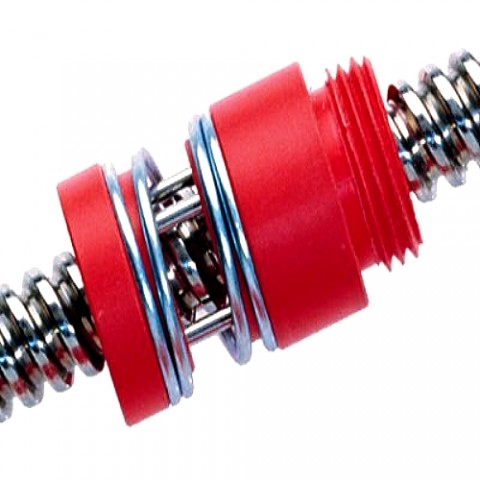

Please do not forget to ask for our competitive support bearing prices !

If you require further technical information, please do not hesitate to contact our sales engineers who will be more than happy to help you with your selection.

Greases and Lubricants

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details. Grease features include, Temperature range -30°C to 150°C, Revolutionary multi-complex soap technology, Greatly extended lubrication intervals typically 3 times longer than conventional soap thickened greases. Good corrosion resistance. Some greases are supplied blue in colour for high visibility.