A traditional lead screw and nut combination requires the driven screw to change its direction of rotation to enable the nut to return to its original start position. However, in certain applications, it may be advantageous to maintain a single direction of rotation of the screw but still have the nut return to the start position.

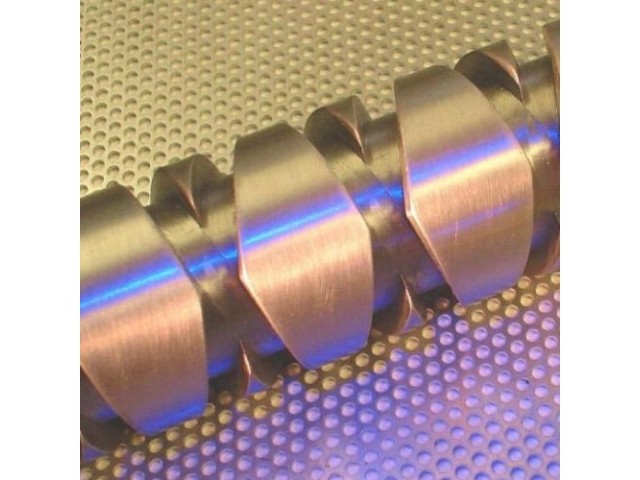

With the self-reversing screw product, only one direction of rotation is required to achieve reciprocated bi-directional lateral movement. The reciprocated bi-directional movement is achieved by using a follower blade in the nut, that is matched to the particular groove width and screw turn round on the screw. Please note that our self reversing screws, do not utilise ball bearings in their linear travel.

There is not a standard range of this screw type as all designs are manufactured to meet the customer's individual specification. Typically, the self reversing lead screws take about 5 - 7 weeks to be manufactured. They can be created in just about any mild steel, stainless steel, bronze or Aluminium. The nut can be supplied in a style and size according to your requirements. (Most small self reverser screws are 3/8" diameter with a nut block 30mx30mmx35mm, however, we go up to approx 250mm diameter with lengths up to many metres).

A great example of the self reversing screws placement was in the recent involvement of some confectionery machinery, where it used to produce a shaking motion. Using a screw pitch of 6mm and a 180 degree turnaround through 20mm of bi-directional stroke, the nut housing was made up of a steel follower blade housed in a brass mounting which itself was then housed in a rubber sleeve. All parts where manufactured to drawing and supplied ready to fit under one part number for future reference. Other typical applications include reliable winding of cable and hose to winch drums using gear ratios of either 4:1 or 2:1 where a reciprocating lateral movement is required.

To enable us to quote for this product, we need the data contained in the on line self reversing screw engineering form

Another excellent example of self reversing screw product placement can be seen within the video below, courtesy of Tethered Drone Systems Limited.

ABSSAC's self-reversing screw product does not require the driven screw to change its direction of rotation to enable the nut to return to its original start position.

The reciprocated bi-directional movement is achieved by using a follower blade in the nut, that is matched to the particular groove width and screw turn round on the screw. (Our self reversing screws, do not utilise ball bearings in their linear travel). The video shows the basic mechanics of the design we utilise.