Consider the Sure-Flex® flexible shaft coupling range available from Abssac, which was designed specifically with that industry in mind. With large stocks kept, we offer an excellent solution to your pump coupling requirements. The easy to fit Sure-Flex® elastomeric shaft couplings rely on a proven element produced from a elastic polymer, to absorb the shaft misalignments but also transmit torque whilst simultaneously dealing with shock and vibration. Sure-Flex® shaft couplings can be installed quickly and easily because there are no bolts, gaskets, covers or seals. Alignment can be checked with a straight edge placed across the outside of the precision machined flanges. No special tools are needed for installation, alignment or removal.

Mr. Phil Jones, from Abssac says“ The teeth of the sleeve lock into the teeth of the flanges without clamps or screws, tightening under torque to provide smooth transmission of power. Since there is no rubbing action of metal against rubber to cause wear, the couplings are not affected by abrasives, dirt or moisture. This eliminates the need for lubrication or maintenance, whilst providing clean dependable, quiet performance.”

The 4-way flexing action absorbs virtually all types of shock, misalignment and end float. With Sure-Flex couplings, the need for lubrication and maintenance is also eliminated. As a result, the couplings provide clean, dependable and quiet performance for a variety of applications.

Flexing action #1 -TORSIONAL Flexibility !

Sure-Flex coupling sleeves have an exceptional ability to absorb torsional shock and dampen torsional vibrations. The EPDM and Neoprene sleeves wind-up approximately 15° torsionally at their rated torque. Hytrel sleeves will wind-up about 7°.

Flexing action #2 - ANGULAR Flexibility !

The unique design of the Sure-Flex coupling's teeth allows for the absorption of angular misalignment without wear. These limits allow for the alignment of the coupling using only a scale and calipers.

Flexing action #3 - PARALLEL Flexibility !

Parallel misalignment is absorbed without wear or appreciable energy losses. The lateral flexibility of the coupling sleeve minimizes radial bearing loads normally associated with parallel misalignment. This feature also allows for easier installation by the use of components bored for slip fits without fretting corrosion occurring at the shaft. Only a straight-edge and feeler gage are required to obtain these limits.

Flexing action #4 - AXIAL Flexibility !

Sure-Flex couplings may be used in applications where there are limited axial shaft movements. The axial compressibility of the EPDM and Neoprene sleeves allows for shaft end-float without the absolute transfer of thrust loads.

With knowledgeable staff always available, we stock and supply the Sure-Flex® elastomeric shaft coupling. The basic coupling uses two cast hubs available prebored or pilot bored and a proven centre element produced from a elastic polymer, to compensate for ardous shaft misalignments. The proven product delivers reliable torque transmission whilst simultaneously dealing with shock and vibration. EPDM and Neoprene sleeves have excellent dampening properties where as the Hytrel sleeves are for higher torques and petrochemical resistance.

Sure-Flex® shaft couplings can be installed quickly and easily because there are no bolts, gaskets, covers or seals. Alignment can be checked with a straight edge placed across the outside of the precision machined flanges. No special tools are needed for installation, alignment or removal. Their 4-way flexing action absorbs virtually all types of shock, misalignment, and end float. With Sure-Flex couplings, the need for lubrication and maintenance is also eliminated. As a result, these couplings provide clean, dependable, and quiet performance for a variety of applications.

The Lubrication-free design provides quiet, reliable performance.

The uniquely designed teeth allow lateral flexibility whilst accepting both parallel and angular misalignment without wear.

If you require further technical information, please do not hesitate to contact our sales engineers who will be more than happy to help you with your selection.

| Sleeve Material | EPDM | NEOPRENE | HYTREL | URETHANE |

|---|---|---|---|---|

| Available Sleeve Styles | Style designator | |||

| 1 pc, unsplit | JE | JN | H | U |

| 1 pc, split | JES | JNS | - | - |

| 2 piece | E | N | HS | - |

| Typical Use | General Purpose | Oil Resist Non-flame | General Purpose | Stiffness |

| Torsional wind up | 15° | 15° | 7° | 3° |

| Angular Misalignment | 1° | 1° | 1/4° | 1/4° |

| Temperature (C°) | ||||

| Maximum | +135° | +94° | +122° | +94° |

| Minimum | -34° | -17° | -54° | -63° |

| Product No. | Product Description | Product No. | Product Description | Product No. | Product Description | ||

|---|---|---|---|---|---|---|---|

| 3J | 3JE EPDM | 4 | 4E EPDM | 6H | 6H Hytrel | ||

| 4J | 4JE EPDM | 5 | 5E EPDM | 7H | 7H Hytrel | ||

| 5J | 5JE EPDM | 6 | 6E EPDM | 8H | 8H Hytrel | ||

| 6J | 6JE EPDM | 7 | 7E EPDM | 9H | 9H Hytrel | ||

| 7J | 7JE EPDM | 8 | 8E EPDM | 10H | 10H Hytrel | ||

| 8J | 8JE EPDM | 9 | 9E EPDM | 11H | 11H Hytrel | ||

| 9J | 9JE EPDM | 10 | 10E EPDM | 12H | 12H Hytrel | ||

| 10J | 10JE EPDM | 11 | 11E EPDM | ||||

| 12 | 12E EPDM | 6HS | 6HS Split Hytrel | ||||

| 3JS | 3JES EPDM Split | 13 | 13E EPDM | 7HS | 7HS Split Hytrel | ||

| 4JS | 4JES EPDM Split | 14 | 14E EPDM | 8HS | 8HS Split Hytrel | ||

| 5JS | 5JES EPDM Split | 16 | 16E EPDM | 9HS | 9HS Split Hytrel | ||

| 6JS | 6JES EPDM Split | 10HS | 10HS Split Hytrel | ||||

| 7JS | 7JES EPDM Split | 4N | 4N Neoprene | 11HS | 11HS Split Hytrel | ||

| 8JS | 8JES EPDM Split | 5N | 5N Neoprene | 12HS | 12HS Split Hytrel | ||

| 9JS | 9JES EPDM Split | 6N | 6N Neoprene | 13HS | 13HS Split Hytrel | ||

| 10JS | 10JES EPDM Split | 7N | 7N Neoprene | 14HS | 14HS Split Hytrel | ||

| 8N | 8N Neoprene | ||||||

| 3JN | 3JN Neoprene | 9N | 9N Neoprene | 10U | 10U Urethane | ||

| 4JN | 4JN Neoprene | 10N | 10N Neoprene | 11U | 11U Urethane | ||

| 5JN | 5JN Neoprene | 11N | 11N Neoprene | 12U | 12U Urethane | ||

| 6JN | 6JN Neoprene | 12N | 12N Neoprene | ||||

| 7JN | 7JN Neoprene | 13N | 13N Neoprene | ||||

| 8JN | 8JN Neoprene | 14N | 14N Neoprene | ||||

| 3JNS | 3JNS Neoprene Split | ||||||

| 4JNS | 4JNS Neoprene Split | ||||||

| 5JNS | 5JNS Neoprene Split | ||||||

| 6JNS | 6JNS Neoprene Split | ||||||

| 7JNS | 7JNS Neoprene Split | ||||||

| 8JNS | 8JNS Neoprene Split | ||||||

| Size | EPDM Sleeves | Neoprene Sleeves | KW @ RPM | Torque (Nm) | Stiffness (Nm/rad) | Max RPM | |||

|---|---|---|---|---|---|---|---|---|---|

| 100 | 970 | 1450 | 3000 | ||||||

| 3 | JE,JES | JN,JNS | 0.07 | 0.69 | 1.03 | 2.13 | 6.8 | 26 | 9200 |

| 4 | E,JE,JES | N,JN,JNS | 0.14 | 1.38 | 2.06 | 4.26 | 13.6 | 52 | 7600 |

| 5 | E,JE,JES | N,JN,JNS | 0.28 | 2.75 | 4.12 | 8.52 | 27.1 | 104 | 7600 |

| 6 | E,JE,JES | N,JN,JNS | 0.53 | 5.16 | 7.72 | 15.97 | 50.8 | 194 | 6000 |

| 7 | E,JE,JES | N,JN,JNS | 0.86 | 8.32 | 12.44 | 25.73 | 82.0 | 313 | 5250 |

| 8 | E,JE,JES | N,JN,JNS | 1.34 | 13.03 | 19.47 | 40.29 | 128.2 | 490 | 4500 |

| 9 | E,JE,JES | N | 2.13 | 20.66 | 30.88 | 63.89 | 203.4 | 777 | 3750 |

| 10 | E,JE,JES | N | 3.40 | 33.00 | 49.32 | 102.05 | 324.8 | 1241 | 3600 |

| 11 | E | N | 5.36 | 51.99 | 77.72 | 160.79 | 511.8 | 1955 | 3600 |

| 12 | E | N | 8.52 | 82.63 | 123.52 | 255.57 | 813.5 | 3107 | 2800 |

| 13 | E | N | 13.43 | 130.26 | 194.72 | 402.87 | 1282.4 | 4898 | 2400 |

| 14 | E | N | 21.30 | 206.58 | 308.81 | 638.92 | 2033.7 | 7768 | 2200 |

| 16 | E | 55.91 | 542.28 | 810.63 | 1677.16 | 5338.5 | 20392 | 1500 | |

| Size | Hytrel Sleeves | Urethane Sleeves | KW @ RPM | Torque (Nm) | Stiffness (Nm/rad) | Max RPM | |||

|---|---|---|---|---|---|---|---|---|---|

| 100 | 970 | 1450 | 3000 | ||||||

| 6 | H,HS | 2.13 | 20.66 | 30.88 | 63.89 | 203.4 | 1130 | 6000 | |

| 7 | H,HS | 3.40 | 33.00 | 49.32 | 102.05 | 324.8 | 2260 | 5250 | |

| 8 | H,HS | 5.36 | 51.99 | 77.72 | 160.79 | 511.8 | 3390 | 4500 | |

| 9 | H,HS | 8.52 | 82.63 | 123.52 | 255.57 | 813.5 | 5367 | 3750 | |

| 10 | H,HS | U | 13.43 | 130.26 | 194.72 | 402.87 | 1282.4 | 11299* | 3600 |

| 11 | H,HS | U | 21.30 | 206.58 | 308.81 | 638.92 | 2033.7 | 14123* | 3600 |

| 12 | H,HS | U | 37.27 | 361.52 | 540.42 | 1118.11 | 3559.0 | 25422* | 2800 |

| 13 | HS | 55.93 | 542.49 | 810.94 | 1677.80 | 5340.6 | 41680 | 2400 | |

| 14 | HS | 85.76 | 831.84 | 1243.48 | 2572.71 | 8189.1 | 67028 | 2200 | |

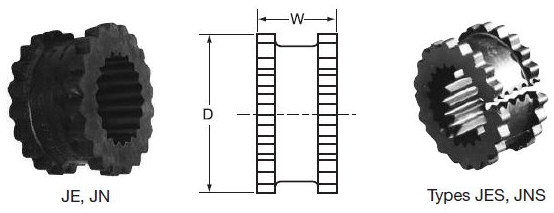

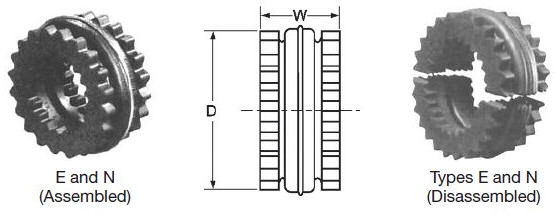

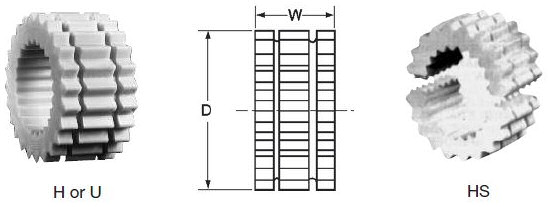

Flexible sleeves for Sure-Flex couplings are available in four materials (EPDM, Neoprene, Hytrel and Urethane) and in three basic constructions. The various types are shown and described here.

| JE-JES-JN-JNS |

|---|---|

J sleeves are molded EPDM rubber (E) or Neoprene (N). They are available in one-piece solid construction (JE, JN) or one-piece split construction (JES, JNS). These sleeves may be used in any Sure-Flex flange within a given size. | |

| E-N |

These sleeves are of two-piece design with a retaining ring. They are available in either EPDM (E) or Neoprene (N). They may be used with any flange within a given size. Sleeves are shown here assembled and disassembled. | |

| H-HS-U |

H (Hytrel) and U (Urethane) sleeves designed for high-torque applications, transmit four times as much power as an equivalent EPDM or Neoprene sleeve. Available in one-piece solid construction (H or U) or two-piece split construction (HS), these can be used only with S, C, and SC flanges. They cannot be used with J or B flanges or as direct replacements for EPDM or Neoprene sleeves. |