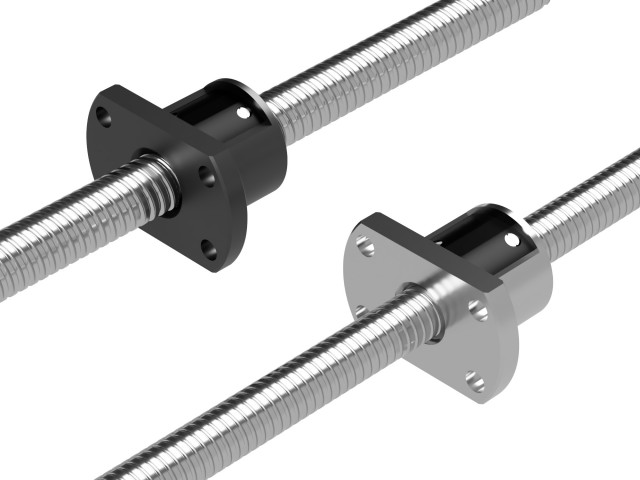

ABSSAC is understood to be the first in the UK to supply a single piece, rolled ball screw that has a thread form right up to the end journal and a diameter that is equal or greater than that of the screw thread diameter. In the past, this format of screw and larger journal has only been possible by using a machined or ground screw thread form or by bonding a section of screw to a separate journal which would inevitably increase the unit cost.

At first glance this innovation seems simple, but when you start to consider the limitations in thread rolling processes and take into account that previously it has been impossible to roll a thread on anything other than a single diameter bar stock, for the entire length of the screw, you start to see the great technological advance. A rolled ball screw will always be more competitively priced than a ground screw equivalent and this has always caused the immiscible dilemma to the design engineer. Use a machined or ground screw to get the larger journal for greater axial thrust attachment security and available bearing choice or sacrifice the larger journal advantage for the less cost rolled screw.

The new SRT ball screw series provides a high linear accuracy allowing the customer to replace expensive ground ball screws with a rolled screw alternative at less cost and with operational confidence. As standard, two precision tolerances are available ; C7-20 (0.05mm/300mm, 20 microns axial play) or C10-50 (0.2mm/300mm, 50 microns axial play). For more performance data, as well as further screw and nut dimensions please feel free to contact us.

| Part Number | Nominal Shaft Diameter (mm) | Lead (mm) | Linear Travel (mm) | Dynamic Load Rating (N) | Static Load Rating (N) |

|---|---|---|---|---|---|

| SRT0401-096R155C7 | 4.0 | 1.00 | 75 | 560 | 790 |

| SRT0401-216R275C7 | 4.0 | 1.00 | 195 | 560 | 790 |

| SRT0401-096R155C10 | 4.0 | 1.00 | 75 | 560 | 790 |

| SRT0401-216R275C10 | 4.0 | 1.00 | 195 | 560 | 790 |

| SRT0402-096R155C7 | 4.0 | 2.00 | 75 | 420 | 570 |

| SRT0402-216R275C7 | 4.0 | 2.00 | 195 | 420 | 570 |

| SRT0402-096R155C10 | 4.0 | 2.00 | 75 | 420 | 570 |

| SRT0402-216R275C10 | 4.0 | 2.00 | 195 | 420 | 570 |

| SRT0504-096R155C7 | 5.0 | 4.00 | 70 | 470 | 720 |

| SRT0504-216R275C7 | 5.0 | 4.00 | 190 | 470 | 720 |

| SRT0504-096R155C10 | 5.0 | 4.00 | 70 | 470 | 720 |

| SRT0504-216R275C10 | 5.0 | 4.00 | 190 | 470 | 720 |

| SRT0601-146R220C7 | 6.0 | 1.00 | 125 | 680 | 1200 |

| SRT0601-261R335C7 | 6.0 | 1.00 | 240 | 680 | 1200 |

| SRT0601-146R220C10 | 6.0 | 1.00 | 125 | 680 | 1200 |

| SRT0601-261R335C10 | 6.0 | 1.00 | 240 | 680 | 1200 |

| SRT0602-146R220C7 | 6.0 | 2.00 | 125 | 750 | 1200 |

| SRT0602-261R335C7 | 6.0 | 2.00 | 240 | 750 | 1200 |

| SRT0602-146R220C10 | 6.0 | 2.00 | 125 | 750 | 1200 |

| SRT0602-261R335C10 | 6.0 | 2.00 | 240 | 750 | 1200 |

| SRT0606-146R220C7 | 6.0 | 6.00 | 125 | 870 | 1450 |

| SRT0606-261R335C7 | 6.0 | 6.00 | 240 | 870 | 1450 |

| SRT0606-146R220C10 | 6.0 | 6.00 | 125 | 870 | 1450 |

| SRT0606-261R335C10 | 6.0 | 6.00 | 240 | 870 | 1450 |

| SRT0610-146R220C7 | 6.0 | 10.00 | 120 | 950 | 1600 |

| SRT0610-261R335C7 | 6.0 | 10.00 | 235 | 950 | 1600 |

| SRT0610-146R220C10 | 6.0 | 10.00 | 120 | 950 | 1600 |

| SRT0610-261R335C10 | 6.0 | 10.00 | 235 | 950 | 1600 |

| SRT0801-196R270C7 | 8.0 | 1.00 | 175 | 780 | 1650 |

| SRT0801-356R430C7 | 8.0 | 1.00 | 335 | 780 | 1650 |

| SRT0801-196R270C10 | 8.0 | 1.00 | 175 | 780 | 1650 |

| SRT0801-356R430C10 | 8.0 | 1.00 | 335 | 780 | 1650 |

| SRT0802-196R270C7 | 8.0 | 2.00 | 170 | 2400 | 4100 |

| SRT0802-356R430C7 | 8.0 | 2.00 | 330 | 2400 | 4100 |

| SRT0802-196R270C10 | 8.0 | 2.00 | 170 | 2400 | 4100 |

| SRT0802-356R430C10 | 8.0 | 2.00 | 330 | 2400 | 4100 |

| SRT0802.5-196R270C7 | 8.0 | 2.50 | 180 | 1850 | 3000 |

| SRT0802.5-356R430C7 | 8.0 | 2.50 | 340 | 1850 | 3000 |

| SRT0802.5-196R270C10 | 8.0 | 2.50 | 180 | 1850 | 3000 |

| SRT0802.5-356R430C10 | 8.0 | 2.50 | 340 | 1850 | 3000 |

| SRT0805-196R270C7 | 8.0 | 5.00 | 165 | 1850 | 3000 |

| SRT0805-356R430C7 | 8.0 | 5.00 | 325 | 1850 | 3000 |

| SRT0805-196R270C10 | 8.0 | 5.00 | 165 | 1850 | 3000 |

| SRT0805-356R430C10 | 8.0 | 5.00 | 325 | 1850 | 3000 |

| SRT0808-196R270C7 | 8.0 | 8.00 | 175 | 2200 | 3800 |

| SRT0808-356R430C7 | 8.0 | 8.00 | 335 | 2200 | 3800 |

| SRT0808-196R270C10 | 8.0 | 8.00 | 175 | 2200 | 3800 |

| SRT0808-356R430C10 | 8.0 | 8.00 | 335 | 2200 | 3800 |

| SRT0812-196R270C7 | 8.0 | 12.00 | 165 | 2200 | 4000 |

| SRT0812-356R430C7 | 8.0 | 12.00 | 325 | 2200 | 4000 |

| SRT0812-196R270C10 | 8.0 | 12.00 | 165 | 2200 | 4000 |

| SRT0812-356R430C10 | 8.0 | 12.00 | 325 | 2200 | 4000 |

| SRT1002-196R270C7 | 10.0 | 2.00 | 170 | 2700 | 5300 |

| SRT1002-396R470C7 | 10.0 | 2.00 | 370 | 2700 | 5300 |

| SRT1002-196R270C10 | 10.0 | 2.00 | 170 | 2700 | 5300 |

| SRT1002-396R470C10 | 10.0 | 2.00 | 370 | 2700 | 5300 |

| SRT1005-196R270C7 | 10.0 | 5.00 | 170 | 3000 | 5200 |

| SRT1005-396R470C7 | 10.0 | 5.00 | 370 | 3000 | 5200 |

| SRT1005-196R270C10 | 10.0 | 5.00 | 170 | 3000 | 5200 |

| SRT1005-396R470C10 | 10.0 | 5.00 | 370 | 3000 | 5200 |

| SRT1010-196R270C7 | 10.0 | 10.00 | 170 | 3300 | 5900 |

| SRT1010-396R470C7 | 10.0 | 10.00 | 370 | 3300 | 5900 |

| SRT1010-196R270C10 | 10.0 | 10.00 | 170 | 3300 | 5900 |

| SRT1010-396R470C10 | 10.0 | 10.00 | 370 | 3300 | 5900 |

| SRT1015-196R270C7 | 10.0 | 15.00 | 160 | 3300 | 6400 |

| SRT1015-396R470C7 | 10.0 | 15.00 | 360 | 3300 | 6400 |

| SRT1015-196R270C10 | 10.0 | 15.00 | 160 | 3300 | 6400 |

| SRT1015-396R470C10 | 10.0 | 15.00 | 360 | 3300 | 6400 |

| SRT1020-196R270C7 | 10.0 | 20.00 | 170 | 2100 | 4000 |

| SRT1020-396R470C7 | 10.0 | 20.00 | 370 | 2100 | 4000 |

| SRT1020-196R270C10 | 10.0 | 20.00 | 170 | 2100 | 4000 |

| SRT1020-396R470C10 | 10.0 | 20.00 | 370 | 2100 | 4000 |

| SRT1202-196R270C7 | 12.0 | 2.00 | 170 | 3000 | 6400 |

| SRT1202-396R470C7 | 12.0 | 2.00 | 370 | 3000 | 6400 |

| SRT1202-196R270C10 | 12.0 | 2.00 | 170 | 3000 | 6400 |

| SRT1202-396R470C10 | 12.0 | 2.00 | 370 | 3000 | 6400 |

| SRT1210-196R270C7 | 12.0 | 10.00 | 165 | 5100 | 9800 |

| SRT1210-396R470C7 | 12.0 | 10.00 | 365 | 5100 | 9800 |

| SRT1210-196R270C10 | 12.0 | 10.00 | 165 | 5100 | 9800 |

| SRT1210-396R470C10 | 12.0 | 10.00 | 365 | 5100 | 9800 |

| SSRT0601-146R220C7 | 6.0 | 1.00 | 125 | 560 | 900 |

| SSRT0601-261R335C7 | 6.0 | 1.00 | 240 | 560 | 900 |

| SSRT0601-146R220C10 | 6.0 | 1.00 | 125 | 560 | 900 |

| SSRT0601-261R335C10 | 6.0 | 1.00 | 240 | 560 | 900 |

| SSRT0801-196R270C7 | 8.0 | 1.00 | 175 | 630 | 1250 |

| SSRT0801-356R430C7 | 8.0 | 1.00 | 335 | 630 | 1250 |

| SSRT0801-196R270C10 | 8.0 | 1.00 | 175 | 630 | 1250 |

| SSRT0801-356R430C10 | 8.0 | 1.00 | 335 | 630 | 1250 |

| SSRT0802-196R270C7 | 8.0 | 2.00 | 170 | 1950 | 3100 |

| SSRT0802-356R430C7 | 8.0 | 2.00 | 330 | 1950 | 3100 |

| SSRT0802-196R270C10 | 8.0 | 2.00 | 170 | 1950 | 3100 |

| SSRT0802-356R430C10 | 8.0 | 2.00 | 330 | 1950 | 3100 |

| SSRT1002-196R270C7 | 10.0 | 2.00 | 170 | 2200 | 4000 |

| SSRT1002-396R470C7 | 10.0 | 2.00 | 370 | 2200 | 4000 |

| SSRT1002-196R270C10 | 10.0 | 2.00 | 170 | 2200 | 4000 |

| SSRT1002-396R470C10 | 10.0 | 2.00 | 370 | 2200 | 4000 |

Fixed side, end-journal is set up bigger than shaft nominal diameter and is unfinished. This allows more design flexibility compared to current rolled ball screws. It is possible to design end-journal configuration compatible with SG series. There are also Integrated rolled ball screws made of stainless steel (SSRT series) available for quick delivery.

If you are interested in the using the ball screw ranges, do not forget that we also supply the full range of linear guides and rails which can provide the load support in your linear mechanism. Offering excellent rigidity and parallelism during operation the guides can be used in both vertical and horizontal planes.

If you are interested in the using the ball screw ranges, do not forget that we also supply the full range of linear guides and rails which can provide the load support in your linear mechanism. Offering excellent rigidity and parallelism during operation the guides can be used in both vertical and horizontal planes.

Following the link to that product page Guides

.jpg)

Please do not forget to ask for our competitive support bearing prices !

If you require further technical information, please do not hesitate to contact our sales engineers who will be more than happy to help you with your selection.

Greases and Lubricants

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details. Grease features include, Temperature range -30°C to 150°C, Revolutionary multi-complex soap technology, Greatly extended lubrication intervals typically 3 times longer than conventional soap thickened greases. Good corrosion resistance. Some greases are supplied blue in colour for high visibility.