The basic process begins with a piece of aluminium stock or bar. Next the internal geometry of the electroform is machined into the aluminium to produce a mandrel. After inspection, nickel, copper, gold, silver or combinations there of are electrodeposited onto the mandrel to a precise wall thickness. Following a post plate inspection the plated mandrel is trimmed to produce the desire end configuration and dimensions. Finally, the aluminium mandrel is then dissolved in a caustic solution leaving behind the completed electroform. At this point special finishes or coatings may be applied.

The process begins with a piece of aluminium stock or bar

Next the internal geometry of the electroform or bellows is machined into the aluminium. This machined part is called a mandrel

After inspection, nickel, copper, gold, silver or combinations thereof are electrodeposited onto the mandrel to precise wall thickness

Following post-plate inspection, the plated mandrel is trimmed to produce the desired end configuration and dimensions

Finally, the aluminium mandrel is dissolved in caustic solution, leaving behind the completed electroform or bellows. At this point special finishes or coatings may be applied.

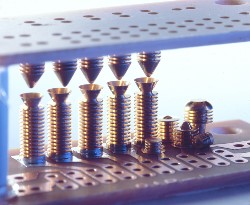

Here is an example where the internal geometry of the electroform is optimised to its full potential (Light baffle application)

The technology offered can and has been used on a hole range of applications in aerospace, medical equipment, electronic chip manufacture, microwave applications, cryogenic cooling and PCB automatic testing activity to name a few. The quality is of the best and where the miniature metal bellows are concerned there are none that compete with bellow diameters under 6mm and on request we can supply down to diameters of 0.07mm.

Some advantages of our electroforms:

SUB-ASSEMBLY SERVICES

We also offer a range of efficient precision assembly services that reduce component costs, lead-times, and sustain quality. We specialise in soldering, induction brazing, electron-beam welding and adhesive bonding. Evacuated assembly, hermetic sealing and back-fill operations routinely produce precision temperature and pressure sensitive devices.Our sub assembly capabilities, combined with necessary leading-edge technologies, will get your job done exactly right - on spec, on time, every time.

ADVANTAGES:

.jpg)

Custom electroforms can be used as extremely precise volume changing devices.

For example; as a volume compensator, the electroformed part can compensate for the changes in volume of a fluid in a sealed container. A bellows volume compensator is in effect a controlled precision bubble, which will change its volume to compensate for the changes in the fluid volume. Likewise, the same electroform can also be used as athermalization assembly - which accurately converts temperature change in to a predicted linear motion.

By filling a custom bellows assembly with an engineered fluid with a known coefficient of expansion, allows the expansion and or contraction, to compress or extend the bellows translating the motion into an accurate linear deflection.

For further details, why not contact our sales engineers who will be happy to discuss your application.

.jpg) The electroforming technology allows us to now supply solid gold electroforms. Electrodeposited products are formed by machining a precision mandrel to the shape of the desired form and then depositing the correct thickness of quality metal on to the mandrel. The mandrel is then dissolved away leaving the precision finished product behind.

The electroforming technology allows us to now supply solid gold electroforms. Electrodeposited products are formed by machining a precision mandrel to the shape of the desired form and then depositing the correct thickness of quality metal on to the mandrel. The mandrel is then dissolved away leaving the precision finished product behind.

Enabling the use of gold within applications has allowed some remarkable properties of the material to be exploited. For example, gold is the most non-reactive of all metals. It is benign in all natural and industrial environments. Gold does not react with oxygen, which means it will not oxidise or tarnish. Gold is among the most electrically conductive of all metals and is able to convey even a tiny electrical current in temperatures varying from -55° to +200° centigrade. Gold is also the most reflective and least absorptive material of infrared (or heat) energy. High purity gold reflects up to 99% of infrared rays but is it also an excellent conductor of thermal energy or heat. Lastly, Gold is ideal for invasive or implantable medical devices as it is one of the least rejected materials in the human body. This unique combination of properties makes gold a vital component in many medical, industrial, and electrical applications.

By refining the gold electroforming technique we can supply extremely intricate parts with unusual shapes, thin walls, deep crevices and other design features. The electroforming process is especially crafted for tolerance-critical miniature parts and makes them suitable for both flexible bellows and rigid electroformed components.The controlled electroforming process can also vary the wall thickness in different places on the same part for selective rigidity and flexibility allowing hollow parts with walls as thin as 0.0127mm (0.0005inch) for miniature applications including electrical bellows contacts and precision instrument applications.

Abssac has supplied bellows spring contacts where the connection cannot or should not be permanent, particularly when the parts are to be connected, separated and re-connected. The two types of spring contacts best suited for these applications are gold-plated wire mesh cylinders and gold-plated miniature metal bellows. Typical applications include: diodes, delay lines, waveguide components, and printed circuit boards.Our bellows type contact springs are manufactured from electrodeposited nickel alloy, and gold plated according to ASTM B 488-01 to enhance their conductivity. They are flexible and dynamic, and designed to provide a lifetime of reliable interconnection. Furthermore, they can help overcome tolerance buildup and thermal expansion problems in critical assemblies.

ADVANTAGES:

For high frequency applications, bellows contacts have low losses ranging from .20 dB to .45 dB at 6 GHz with a total bandwidth much higher. The above information gives you a concise overview of the product capabilities. If you require more detailed information please feel free to contact our sales engineers, who will be more than happy to help.