ETP-MINI is available as standard for shafts 6-14 mm, with imperial sizes also available. Run out ≤ 0,02 mm. Number of mountings 100 (size dependent). The ETP MINI has an extremely compact design with low weight and inertia.

This is a simple mechanical connection consisting of two partly slotted, conical sleeves and cap head clamping screws.

By tightening the cap head screws,cuases the inner sleeve to be pressed against the shaft and the outer sleeve against the hub. This forms the rigid clamped joint. To unclamp the unit simply remove all the cap head screws and use the two threaded dismantling holes on the hub to reverse the clamping process.

![]()

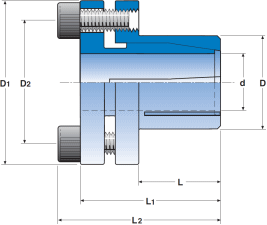

| ETP-Mini® | Dimensions | Transmittable | Screws** DIN 912, 12.9 | Polar moment of inertia J kgm2 • 10-6 | Weight kg | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| torque or axial force | ||||||||||||||

| d mm | D mm | D1 mm | D2 mm | L mm | L1* mm | L2* mm | T Nm | FA kN | No. | Dim. | Tt Nm | |||

| 6 | 6 | 14 | 25 | 18 | 10 | 19 | 22 | 7 | 2,5 | 2 | M3 | 2 | 2,1 | 0,03 |

| 1/4” | 6,35 | 14 | 25 | 18 | 10 | 19 | 22 | 8 | 2,5 | 2 | M3 | 2 | 2,1 | 0,03 |

| 8 | 8 | 15 | 27 | 20 | 12 | 21,5 | 25,5 | 20 | 5 | 2 | M4 | 4 | 3,3 | 0,04 |

| 9 | 9 | 16 | 28 | 21 | 14 | 24 | 28 | 28 | 6,5 | 2 | M4 | 4 | 4,4 | 0,05 |

| 3/8” | 9,525 | 16 | 28 | 21 | 14 | 24 | 28 | 30 | 6,5 | 2 | M4 | 4 | 4,4 | 0,05 |

| 10 | 10 | 16 | 28 | 21 | 14 | 24 | 28 | 34 | 6,5 | 2 | M4 | 4 | 4,3 | 0,05 |

| 11 | 11 | 18 | 30 | 23 | 14 | 25,5 | 29,5 | 36 | 6,5 | 2 | M4 | 4 | 6,2 | 0,06 |

| 12 | 12 | 18 | 30 | 23 | 14 | 25,5 | 29,5 | 40 | 6,5 | 2 | M4 | 4 | 6,1 | 0,06 |

| 1/2” | 12,7 | 18 | 30 | 23 | 14 | 25,5 | 29,5 | 42 | 6,5 | 2 | M4 | 4 | 6,0 | 0,06 |

| 14 | 14 | 22 | 35 | 27 | 15 | 27,5 | 31,5 | 66 | 9,5 | 3 | M4 | 4 | 13,2 | 0,08 |

| T= Transmittable torque when axial force is 0. | } When the screw is tightened to Tt. | * The dimensions are valid before mounting. Dimensions subject to alterations without notice. | ||||||||||||

| FA=Transmittable axial force when torque is 0. | ||||||||||||||

| Tt= Recommended tightening torque for the screws. | ||||||||||||||

![]()

| ETP-Mini® | Dimensions | Transmittable | Screws** DIN 912, A4 | Polar moment of inertia J kgm2 • 10-6 | Weight kg | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| torque or axial force | ||||||||||||||

| d mm | D mm | D1 mm | D2 mm | L mm | L1* mm | L2* mm | T Nm | FA kN | No. | Dim. | Tt Nm | |||

| R-6 | 6 | 14 | 25 | 18 | 10 | 19 | 22 | 5 | 1,7 | 3 | M3 | 1,2 | 2,1 | 0,03 |

| R-8 | 8 | 15 | 27 | 20 | 12 | 21,5 | 25,5 | 17 | 4,4 | 3 | M4 | 2,7 | 3,3 | 0,04 |

| R-9 | 9 | 16 | 28 | 21 | 14 | 24 | 28 | 20 | 4,4 | 3 | M4 | 2,7 | 4,4 | 0,05 |

| R-10 | 10 | 16 | 28 | 21 | 14 | 24 | 28 | 23 | 4,4 | 3 | M4 | 2,7 | 4,3 | 0,05 |

| R-11 | 11 | 18 | 30 | 23 | 14 | 25,5 | 29,5 | 25 | 4,4 | 3 | M4 | 2,7 | 6,2 | 0,06 |

| R-12 | 12 | 18 | 30 | 23 | 14 | 25,5 | 29,5 | 27 | 4,4 | 3 | M4 | 2,7 | 6,1 | 0,06 |

| R-14 | 14 | 22 | 35 | 27 | 15 | 27,5 | 31,5 | 48 | 6,5 | 4 | M4 | 2,7 | 13,2 | 0,08 |

| T= Transmittable torque when axial force is 0. | } When the screw is tightened to Tt. | * The dimensions are valid before mounting. Dimensions subject to alterations without notice. | ||||||||||||

| FA=Transmittable axial force when torque is 0. | ||||||||||||||

| Tt= Recommended tightening torque for the screws. | ||||||||||||||

Shaft k6-h10

Hub H8.

Euronorm 1.4305, stainless steel, X10CrNiS18-9.

** Screws: surface coated for a low and even friction in the threads.

Make sure the screw threads for type R are well lubricated before each mounting. We recommend the use of Omega 58.