Clutches for industrial use are available in three basic designs, giving optimum performance.

The Rota-Cam Clutch utilises the easily installed Roto-Cam®, which completely eliminates external, separately mounted fulcrums, yokes, levers or trunnions and permits a simple, clean compact control system for direct or remote, manual or powered actuation. Roto-Cam provides smooth easy engagement typical of a spring loaded clutch plus a positive, over-centre 'lock-in'. The clutch can be 'inched' or 'Jogged' for complete operator control.

The NLS® centrifugal clutch reduces motor acceleration time and power requirements in a variety of power transmission applications. Offering a low initial starting torque, the NLS clutch provides soft starts and reduced starting current. Because motors achieve running speed almost immediately, motor current and motor heating are reduced.

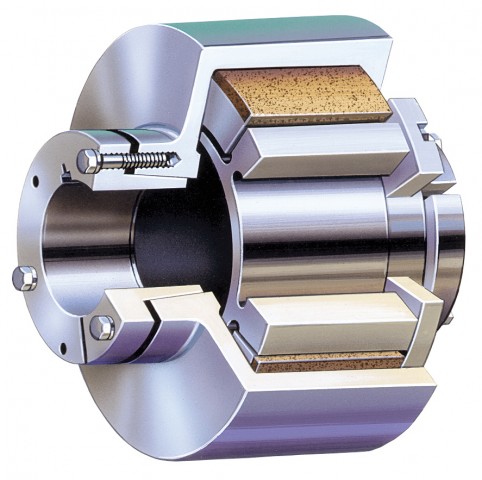

The Disc-o-Torque® Hydraulic clutch are self-contained and require no linkages, levers or adjusting devices. The D5(HTH), D3(STH) and D2(STD) models require no rotating unions, glands, or rifle drilling. Wave springs provide fast, positive disc separation for minimum idling resistance and provide uniform torque capacity during their predictable long life.

If you require further technical information, please do not hesitate to contact our sales engineers who will be more than happy to help you with your selection.