With product names like ETP EXPRESS, ETP EXPRESS R, ETP POWER and ETP TECHNO, these products are, as it sounds, designed for a multitude of applications. In each case only a single screw is used for mounting and dismounting of the hub. This simple feature ensures an extremely quick and easy service interval time and incredibly easy adjustment or re-positioning of the hub. The single screw hubs are used in a variety of applications and industries such as packaging machinery, where finite adjustment o the hubs position can easily be carried out.

The standard ETP-TECHNO and ETP-EXPRESS are available for shafts 15mm to 130mm. ETP-EXPRESS R, Stainless steel versions, are available to suit shafts from 15mm to 80mm.One of the most innovative products on the market, the ETP product consist of a double-walled hardened steel (in some cases stainless steel) sleeve, which is filled with a pressure medium. The precision machine housing contains a threaded pressure screw, that when actuated, moves an internal piston that in turn provides the pressure adjustment. By tightening the pressure screw to a predetermined torque, an even and moderately high surface pressure is created against the shaft and hub, causing the locking effect.

The scientist Blaise Pascal formulated the principle of pressure propagation in liquids many years ago: Pascal's law or the principle of transmission of fluid-pressure states that , ”pressure exerted anywhere in a confined in-compressible fluid is transmitted equally in all directions throughout the fluid such that the pressure ratio (initial difference) remains the same”. The ETP product utilises the many positive qualities of this principle and has continued to develop it further so that it can be utilised reliably and accurately within industrial applications.Whether the hubs are to be removed or re-positioned, mounting and dismantling the process is done in less than a few minutes.

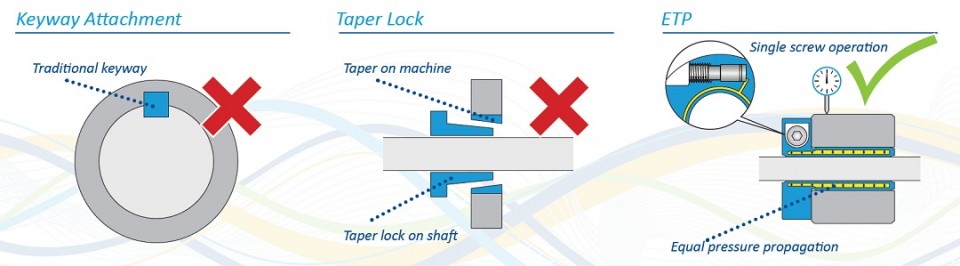

Keyways, will always have a legitimate place in power transmission, but when you need finite adjustment of the driven shaft, keyways are not ideal. The taper lock design allows the positional movement but they are time consuming to fit, release and then re fit. The design is also prone to corrode and become fixed to the shaft over time. Lastly, the taper lock design requires that there is taper on the inside diameter of the driven part, for the device to lock in position and also requires more space to fit because of the bolting circle.

The ETP product eliminates the requirement for keyways or taper locks.