Choosing the correct nut for the lead screw, need not be a headache. We have standard nut designs to suit most applications and when you want a nut to incorporate some special form of attachment or load we can also help.

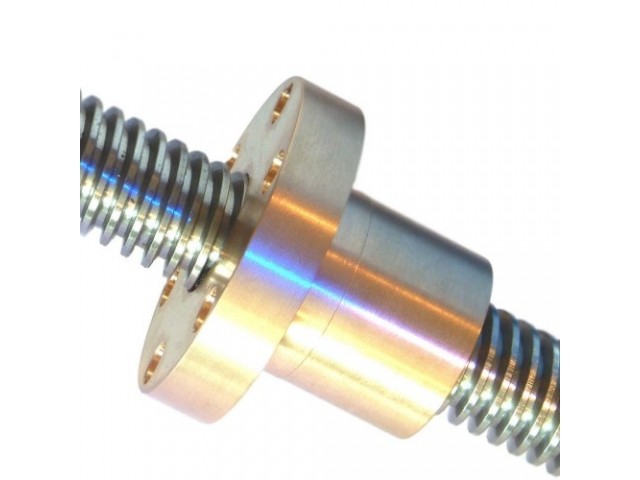

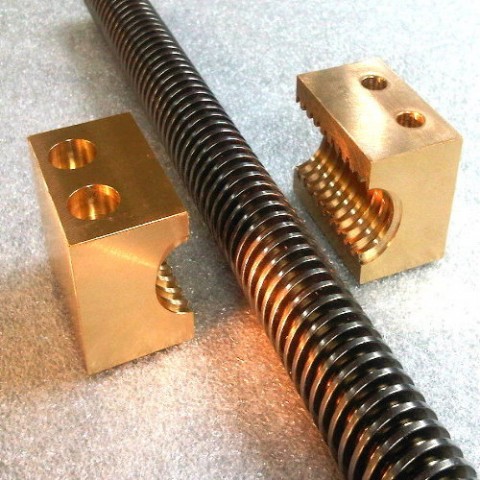

Primarily we use Delrin as our base material for the plastic nuts. Delrin is an acetal resin engineering plastic and is often used as a metal substitute. Delrin is lightweight, has a low coefficient of friction, is extremely wear-resistant and capable of operating in temperatures in excess of 90 degrees Celsius (approx 200 degrees Fahrenheit). Other plastic materials we use are: polyoxymethylene (POM), acetal resin, polytrioxane and polyformaldehyde. Bronze nuts are normally machined from SAE660 bronze but we have also machined in aluminium bronze hybrids for certain applications.

The ability to supply a professionally tapped nut, matched to the thread form of the supplied lead screw is the key to supplying quality linear application products. In many cases screw stock and specialised nut designs are purchased from different sources which can lead to poor fitting of the nut, excessive wear, backlash and low efficiency to the whole linear package. When the engineer requires a more sophisticated nut design the chances are, the part has more importance in the workings of the machine. By supplying both items from the one source, Abssac Limited eliminates this area of potential trouble. The designer can also utilise the experience of its engineers to incorporate many features into the nut design in complete confidence.

To date many bespoke nut designs have been successfully supplied by Abssac, including optical mounts, cams, external threads, mounting holes, pulley grooves, tangs and linear guides to name a few. Abssac offers a vast range of lead screw sizes range from 4mm diameter up to 200mm with a wide range of both metric and imperial leads per diameter. Abssac supplies, cold rolled, whirled, machined and ground style lead screw formats in stainless steel, low carbon steel and exotic materials if required. Nuts can be manufactured from advanced engineering plastics such as Delrin, PTFE or Turcite or in Bronze, Aluminium Bronze and steels as standard.

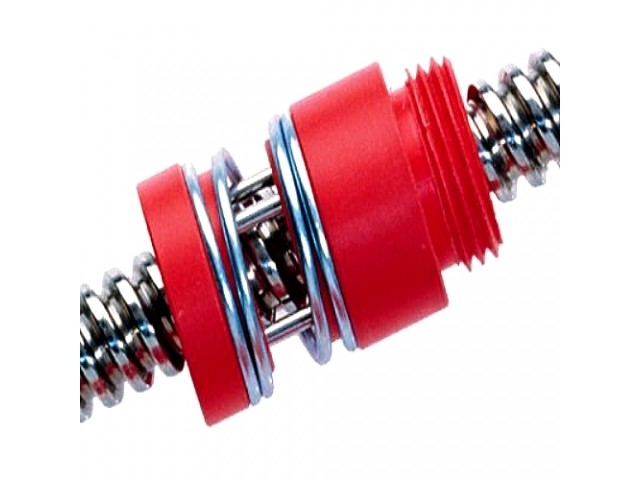

One new nut design utilises a revolutionary cam collar, which will eliminate the backlash, maintain a high axial stiffness and simultaneously reduce drag friction. Other designs enable lighter loads (up to 4.5kg) smooth movement and low drag torque for very little cost. Some nut designs utilise the latest technology in injection moulding techniques to produce the precision form complete with an integral three holed attachment flange for ease of connection to the application. This particular nut has an external spring and collar arrangement which creates the axial preload to eliminate the backlash when on the screw. (Please also note that our antibacklash nut designs compliment the complete range of lead screws and in some cases can be tapped to run on ball screw threads.)

If you require further technical information, please do not hesitate to contact our sales engineers who will be more than happy to help you with your selection.