The benefits of the parallel slit design are not restricted to resonance dampening: The slotted coupling is also ideally suited to applications involving frequent load changes even during reversing duty.

Another standout feature of this coupling is its one-part compact design. The resulting high torsional stiffness and true running accuracy create excellent rotational characteristics that enable high speeds to be achieved.

Thanks to the simple assembly method which can be performed in a matter of seconds sing a single DIN 911 tool, couplings of this type can be incorporated into any drivetrain.

Slotted couplings from the standard range are suitable for shaft diameters ranging from 4mm to 60mm. However, we also offer a large number of special designs that allow you to chose from a wide range of fastening options.

Available fastening options. If our range does not cover a particular installation situation, please contact us and we will be happy to find the right solution to cater for your application.

Slotted coupling with groove for shafts with feather keys

Order example: 080 BB D=32H7/35H7 with groove according to DIN 6885 on both sides

Slotted coupling with quick clamping unit for extreme power transmission

Order example: 100 DD D=42H7/40H7

Slotted coupling with removable clamping hub, easy assembly

Order example: 040BBH D=15H7/18H7

Slotted coupling with special length for bridging large shaft distances

Order example: 070 SL D=32H7/38H7, e.g., L=560mm

Slotted coupling with spread hub for hollow shafts

Order example: 020BC D=6H7/8h6

Slotted coupling with grub screws

Order example: 018 AA D=5H7/5H7

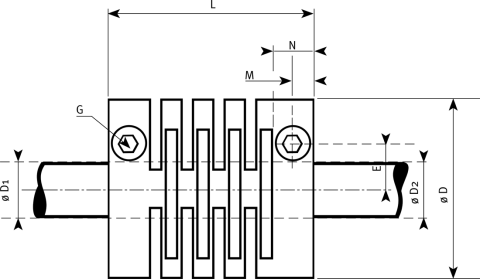

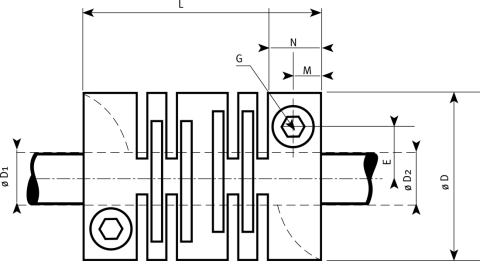

Key 018 BB-022

Key 020-100 BB

Order example: 025 BB D=10H7/10H7

Material: Aluminum alloy; rust-proof design; steel; all parts are also available with a feather key groove. PEEK or titanium also available on request

Speed: > > 6000 rpm; max. speeds of approx. 30,000 rpm on request.

High temperatures of up to 500°C possible.