A recent example of ABSSAC's product placement was in a Glass Coating plant which was aided by the Semiflex shaft coupling. With an ever increasing demand for Low-E demand glass worldwide, high vacuum applications of continuous substrate flow, which can adapt the pressure to process conditions, has meant a huge improvement in glass stability, optical appearance, scratch resistance and standard solar control coatings. With these increasing demands a reliable drive shaft coupling that delivers high torque, reliability and above all contact velocity is required. The Semiflex shaft couplings are preferred in the connection of the rotary vane pumps and root blowers for exactly this reason. Within the sputtering machines the Semiflex shaft coupling is both compact and extremely torsionally stiff. However the Semiflex shaft coupling is also very efficient during operation with no restoring forces required to keep shaft alignment. This is an advantage as the machines can have as many as 10 stages all requiring accurate drive connection.

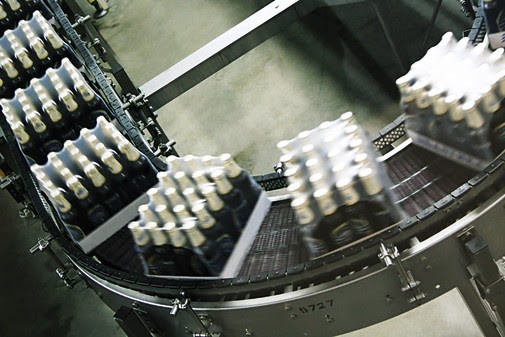

Most of us probably don’t think too much about how that bottle of celebratory bubbly or interesting new micro-brew actually came to be outside of the fermentation process itself; but a lot goes into keeping the beverage industry flowing. Automation of bottling is critical to keeping us all well hydrated. Everything from beer to ketchup, sparkling wine to perfume, and water to soft drinks, come off automated production lines. Machinery includes anything from filling, labelling, and packing bottles and cans, to then taking back plastic bottles (PET) and processing them for reuse. How to improve productivity in a rotary PET bottle stretch blow mould machine? Production of PET bottles is a highly competitive business and the bottle quality has to be excellent. Would the consumer trust the bottled content if the bottle was deficient? The stretch blow moulding machine is the first member in the production chain and the result must be perfect. If there are no bottles – nothing can be bottled, labelled, palletised and sold. The filling and packaging technology market is growing and the goal is to meet the demands of a global market for increased productivity through a maximum machine automation.

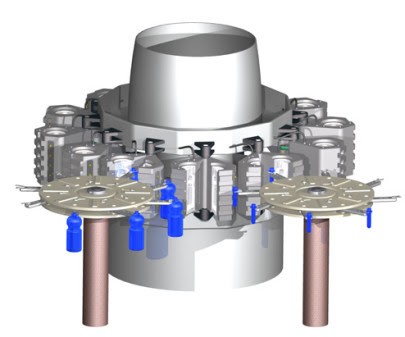

So called preforms of the bottles are inserted into the blow moulding machine via a conveying system. The machine consists of a linear heating module for preform heating and a blow-moulding module in which the heated preforms are blow-moulded into bottles. The preforms initially pass through the heater to achieve elasticity. Next step is the transfer of the preforms into the blow moulds. To fasten and centre the transfer wheel ETP-EXPRESS is used. With the single screw design quick and easy mounting and adjustment is of course a key benefit.

The components of the mould – the two halves and the base – are made largely of aluminium. This allow the mechanical speed potential of the machine to be considerably increased.Depending of machine type the number of individual blow moulds may vary, from 4 up to 36, thus the output of bottles can range from 8 000 up to 72 000 bottles per hour. Stretch blow-moulding machines are often part of a larger production plant, for example a converter line for bottle manufacture or a filling and packaging line. Alongside are machines for filling,labelling, packing and palletising, often controlled via a intelligent conveying and control systems, which ensure a continuous and efficient production process.

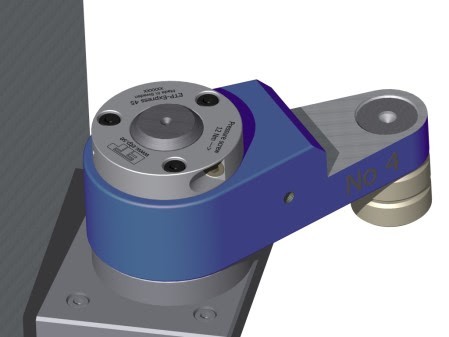

The lever arm of the individual blow mould, for opening and closing of the mould, is a critical application area. In case of a stuck preform or bottle the mould should partially slip against the shaft to avoid further machine damage. Previously traditional mechanical clamping elements have been used leading to extensive downtime when readjusting the moulds. With the use of ETP-EXPRESS operators can quick and easily readjust the blow mould by the single screw feature. Depending on the tolerances and tightening torque a defined slip toque interval will be achieved, also after several slippages. Thus a maximised machine up time and output can be reached.

The worldwide market for PET packaging has now been marked by high growth rates for many years. Beverages such as mineral water and carbonated soft drinks make up the highest percentage of packed products, with the filling of juice,milk and beer in PET increasing more and more. All in all, one cannot place a high enough value on the importance of PET as a material for the food and beverage packaging of the future. The rotary blow mould machines are often recognised within the filling and packaging industry for their unmatched efficiency and the ETP product is a vital part of the design.