Name | Tel | |||||

E-Mail | ||||||

Company | Fax | |||||

Address | ||||||

| Operating Information | ||||||

|---|---|---|---|---|---|---|

| 1. Drive* a or b. Direction c. Continuousd. Reversing e. Stop-Startcycles/sec f. RPMg. Manual 2. Service*a. Operating Torquelbin or Nm. b. Maximum Torquelbin or Nm. 3. Misalignments*a. Angular b. Parallel c. Axial Compression/Extensionsin. or mm d. Skew - please provide sketch | 4. Torsional Rate* deg/lb.in. or deg/Nm a. less thanb. equal toc. greater than 5. Inertial Limitations / Mass Moment of Inertiadeg/lb.in. or deg/Nm a. less thanb. equal toc. greater than 6. Weightoz. or gm a. less thanb. equal toc. greater than 7. Environmenta. Temperature°F or °C b. Corrosive c. Abrasive | |||||

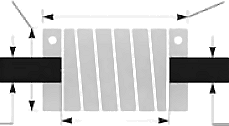

| Flexure and Component Layout | ||||||

8a.* Preferred Outside Diameterin. or mm Maximum Outside Diameterin. or mm | b.* Preferred Lengthin. or mm Maximum Lengthin. or mm | |||||

c. *Driver Description |  | d. *Driver Description | ||||

e.*Shaft Diameter in. or mm | g.*Shaft to Shaft in. or mm | f.*Shaft Diameter in. or mm | ||||

| 9. Bore Tolerance | ATTACHMENTS | 12.Material | ||||

a. Commercial +.002 in. -.000 in. or +.05 mm -.00mm b. Precision +.0005 in. -.0000 in. or +.015 mm -.000mm | 10. Driver* | 11. Driven* | 7075-T6 Aluminium Alloy 17-4 PH Stainless Steel Other | |||

| a | Integral Clamp | a | ||||

| b | 2 Set Screws at 120° | b | ||||

| c | 2 Set Screws at 90° | c | ||||

| d | 1 Set Screw | d | ||||

| e | Roll Pin in. or mm | e | 13.Production Quantity | |||

| f | Dowel Pin in. or mm | f | 1-24 25-100 100+ | * Items marked with an asterisk are essential for optimum design. | ||

| g | Keyway type size | g | ||||

| h | Other/describe below | h | ||||

Type of equpiment | ||||||

Comments | ||||||