As with its wire wound brother, all types of spring format such as, compression, extension, torsion, lateral translation and lateral bending springs are available in the machined format. However, from this point the similarities between wound and machined springs stop. Machined springs can provide very precise, linear deflection rates because virtually all residual stresses are eliminated. As a result, there are no internal stresses to overcome before deflection occurs, which can be the case in the wire wound spring. In addition to this we can offer multiple start spring coil configurations.

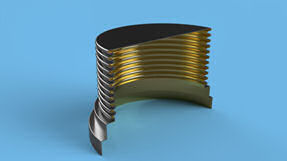

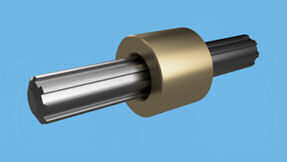

The most common configuration is the single start, which consists of a single continuous coil element, which starts at one end and terminates at the other end, much like its wire wound counterpart. However, we can uniquely offer a double start or indeed triple start spring which has two or three intertwined continuous coil elements.

The advantages of Multiple start spring elements are beneficial because they not only provide redundant elastic elements should a failure occur, but a failed element (coil) will be physically trapped by the remaining one and in many cases will allow the albeit reduced function of the spring design to still operate. Another multi-start benefit applies to compression and tension springs, as when compressed (or extended), single start springs provide a reaction force plus a moment. On multiple start flexures, all internal moments are resolved within the spring itself, which translates into excellent compression or extension parallelism.

There is no tendency for the spring to squirm when deflected, and no restraint is necessary to resolve the free moment. Double and triple start variants make the loading points irrelevant on the radius of the spring but increase the accuracy of parallelism.

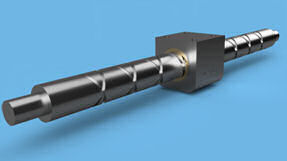

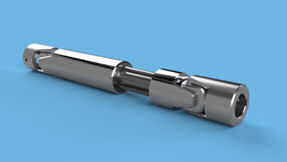

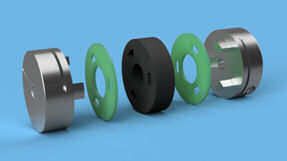

Once the working dynamics of the spring are calculated and agreed we can then look at the method of attachment. In many cases the machined spring incorporates other parts of the working mechanism into the single part, such as flanges, gears, splines etc., making the final item more reliable. If you require more detailed information on the above product, such as physical dimensions, performance data or just to see the full range of products available, please feel free to contact one of our technical sales engineers who will be more than happy to help you.

When considering the dynamics of the machined spring we look at the 6 possible Cartesian co ordinates, those being X,Y,Z and then the rotation ROTX, ROTY & ROTZ. A wound spring tries to deliver all 6 axis potentials when it is asked to move. A machined spring can be a single degree of freedom system, delivering motion in only one of the possible six axis and the double start machined spring is the closest single Cartesian co-ordinate defection part available with todays technology.

Finite Element Analysis (FEA) is employed to verify the feasibility and performance of the machined spring. For example, the stress in compression and extension machined springs is dominantly torsional shear, where as the stress in torsional machined springs is dominantly pure bending stress.

The advantages of the machined spring product are numerous having proven itself in medical, aerospace, semiconductor and motorsport industries to name a few.

Where ever a wound spring is not able to meet your performance criteria or a new spring design requires ultimate accuracy and repeatability, the machined spring is the ideal partner.

Wound

Machined

3 piece to 1 piece design

6 piece to 1 piece design

3 piece to 1 piece design

Single start machined springs can satisfy most applications but in some cases we also consider double start or indeed triple spring configurations which have two or three intertwined continuous coil elements, still within the same single part construction. In effect, this puts multiple independent helixes in the same cylindrical plane, which provides totally enhanced spring performance. With the machined spring, perpendicularity, parallelism, lateral bending, axial and torsional rates can be guaranteed.

We like to think of it as.... PRECISION ELASTICITY.

Multi-start springs have many advantages. When applied to compression and extension springs, a single start spring provides a reaction force plus a moment. On multiple start flexures, all internal moments are resolved within the spring itself, which translates into excellent compression or extension parallelism. Set us the challenge !

ABSSAC Ltd, E1A The Enterprise Centre, Enterprise Way,

Evesham, Worcestershire. United Kingdom. WR11 1GS

Call: 01386 421 005

Email: sales@abssac.co.uk

Visit: www.abssac.co.uk