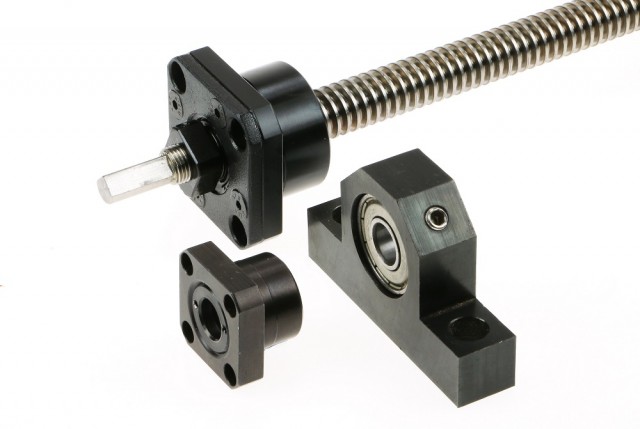

How the ball screw, lead screw or satellite roller screw is fixed to the application has a direct influence on the efficiency, longevity and performance of the linear system. ABSSAC stocks a complete range of bearing sets manufactured specifically for use with linear applications. These bearing designs primarily consist of either thrust or radial bearings that are housed in a pillow block or flange mount. Bearing styles are grouped, for convenience, into the following prefixes of BK Type for thrust pillow block fixed, BF Type for radial simple support, FF Type for flange mount simple support and the FK Type which is a flange mount thrust bearing.

ABSSAC bearing sets are interchangeable with leading brands and are available to suit shaft sizes from 2mm up to 40mm. When choosing bearing sets, it is paramount to consider the type of fixing design against the speed of rotation and column loading of the screw. This information is graphically displayed in the catalogue which can be downloaded from the link above. Shown below are some examples of bearing set ups that cater for most critical speed and column loading scenarios. However, ABSSAC's sales engineers will be more than happy to help you with your selection. PDF and Step file downloads are available for each style of bearing from the table below.

Fixed Free - BK or FK style to nothing

Simple Simple - BF to BF or FF to FF

Fixed Simple - BK or FK to BF or FF

Fixed Fixed - BK or FK to BK or FK

Other bearing styles are available on request.

Fixed Free

Simple Simple

Fixed Simple

Fixed Fixed

Supplying ball and lead screws ready to fit into applications often requires ABSSAC to supply product to a customer drawing specification. Employing turning, grinding, milling and straightening techniques optimises the final product. ABSSAC's machining capability gives you a high journal concentricity product which can be applied to all screws regardless of diameter. Working together can reduce customer scrap rates and enable linear solutions that fit into applications every time. Working directly from dimensional drawings, or if they do not exist, customer owned samples to reverse engineer. Although all types of end machine detail can be supplied, ABSSAC offers a cost effective basic end journal machining that directly matches the range of support bearings (see example diagrams below).

BK Machining

| Model No. | D | D1 | B | E | F | M | S |

| BK-10 | 12/14/15 | 10 | 8 | 36 | 15 | M10x1 | 12 |

| BK-12 | 14/15/16 | 12 | 10 | 36 | 15 | M12x1 | 12 |

| BK-15 | 18/20 | 15 | 12 | 40 | 20 | M15x1 | 12 |

| BK-17 | 20/25 | 17 | 15 | 53 | 23 | M17x1 | 17 |

| BK-20 | 25/28 | 20 | 17 | 53 | 25 | M20x1 | 15 |

| BK-25 | 32/36 | 25 | 20 | 56 | 30 | M25x1.5 | 20 |

| BK-30 | 36/40 | 30 | 25 | 73 | 38 | M30x1.5 | 25 |

| BK-35 | 45 | 35 | 30 | 82 | 45 | M30x1.5 | 26 |

| BK-40 | 50 | 40 | 35 | 84 | 50 | M40x1.5 | 30 |

Optional Keyway

| Model No. | N | P |

|---|---|---|

| BK-10 | 2 | 12 |

| BK-12 | 3 | 12 |

| BK-15 | 4 | 15 |

| BK-17 | 5 | 20 |

| BK-20 | 5 | 20 |

| BK-25 | 6 | 30 |

| BK-30 | 8 | 32 |

| BK-35 | 8 | 40 |

| BK-40 | 10 | 60 |

BF Machining

| Model No. | D | D1 | E | A | B | C |

|---|---|---|---|---|---|---|

| BF-10 | 12/14/15 | 8 | 10 | 7.6 | 0.9 | 7.9 |

| BF-12 | 14/15/16 | 10 | 11 | 9.6 | 1.15 | 9.15 |

| BF-15 | 18/20 | 15 | 13 | 14.3 | 1.15 | 10.15 |

| BF-17 | 20/25 | 17 | 16 | 16.2 | 1.15 | 13.15 |

| BF-20 | 25/28/30 | 20 | 16 | 19 | 1.35 | 13.35 |

| BF-25 | 30/32/36 | 25 | 20 | 23.9 | 1.35 | 16.35 |

| BF-30 | 36/40 | 30 | 21 | 18.6 | 1.75 | 17.75 |

| BF-35 | 40/45 | 35 | 22 | 33 | 1.75 | 18.75 |

| BF-40 | 50 | 40 | 23 | 38 | 1.95 | 19.95 |

FK Machining

| Model No. | D | D1 | E | F | M | S |

|---|---|---|---|---|---|---|

| FK05 | 8 | 5 | 23 | 6 | M5x0.5 | 7 |

| FK08 | 10/12 | 8 | 32 | 9 | M8x1 | 10 |

| FK10 | 12/14/15 | 10 | 36 | 15 | M10x1 | 12 |

| FK12 | 14/15/16 | 12 | 36 | 15 | M12x1 | 12 |

| FK15 | 18/20 | 15 | 48 | 20 | M15x1 | 13 |

| FK17 | 20/25 | 17 | 59 | 23 | M17x1 | 17 |

| FK20 | 25/28/30 | 20 | 64 | 25 | M20x1 | 16 |

| FK25 | 30/32/36 | 25 | 76 | 30 | M25x1.5 | 20 |

| FK30 | 36/40 | 30 | 73 | 38 | M30x1.5 | 25 |

Optional Keyway

| Model No. | N | P |

|---|---|---|

| BK-10 | 2 | 12 |

| BK-12 | 3 | 12 |

| BK-15 | 4 | 15 |

| BK-17 | 5 | 20 |

| BK-20 | 5 | 20 |

| BK-25 | 6 | 30 |

| BK-30 | 8 | 32 |

| BK-35 | 8 | 40 |

| BK-40 | 10 | 60 |

BF Machining

| Model No. | D | D1 | E | A | B | C |

|---|---|---|---|---|---|---|

| FF-10 | 12/14/15 | 8 | 10 | 7.6 | 0.9 | 7.9 |

| FF-12 | 14/15/16 | 10 | 11 | 9.6 | 1.15 | 9.15 |

| FF-15 | 18/20 | 15 | 13 | 14.3 | 1.15 | 10.15 |

| FF-17 | 20/25 | 17 | 16 | 16.2 | 1.15 | 13.15 |

| FF-20 | 25/28/30 | 20 | 16 | 19 | 1.35 | 13.35 |

| FF-25 | 30/32/36 | 25 | 20 | 23.9 | 1.35 | 16.35 |

| FF-30 | 36/40 | 30 | 21 | 18.6 | 1.75 | 17.75 |

| FF-35 | 40/45 | 35 | 22 | 33 | 1.75 | 18.75 |

| FF-40 | 50 | 40 | 23 | 38 | 1.95 | 19.95 |

Drawings in PDF and STP:

Other Abssac services and products

To compliment our product ranges we offer a large range of support products. For example we have had great success in producing copies of lead and ball screws where no formal drawing exists. Customers have shipped the parts for us to dimensionally check and copy into a new physical part. Ancillary products can also include the ranges of lubricants we supply, including our low vapour pressure greases for clean room and vacuum applications. The new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Other services available from Abssac are listed below