Precision lead screws and nuts are integral to numerous mechanical processes around the world. Offering a high mechanical advantage they are utilised to efficiently convert an applied torque, to either the nut or screw, into a precise repeatable linear movement. Thread forms such as Acme, Trapezoidal and Vee thread have all been employed over the years, each of which have their definitive advantages over the other. However choosing the correct lead screw assembly for the application can be a challenge. At Abssac we like to look at the basics of the application and understand the speed, load and repeatable accuracy, which can often quickly determine the screw format for the application. For example, the torque required to move a load can be calculated by "unwrapping" one revolution of a thread. Mechanical efficiencies for lead screws range from 20% - 40% depending upon the lead angle and the coefficient of friction of the nut material. For example, Plastic acme nuts offer approximately 10% - 20% better efficiency than bronze acme nuts. The product program delivers an unparalleled quality product supported by many years of application knowledge, experience and range of thread forms.

Acme Lead Screws

Precision rolled ACME threads have a 2G & 3G thread fit. The lead accuracy over the length of the rod is 0.006inch per foot. (0.15mm per 300mm) Please contact us for further details and sizes.

Trapezoidal Lead Screws

Precision rolled TRAPEZOIDAL threads have a 7E thread fit. The lead accuracy over the length of the rod is 0.08mm per 30cm.

Unified National Lead Screws

Precision rolled UN V threads have a 2A and 3A thread fit. The lead accuracy over the length of the rod is 0.003inch per foot (0.07mm per 300mm) Please contact us for further details and sizes.

Metric M Lead Screws

Precision rolled METRIC M threads have a 4G thread fit. The lead accuracy over the length of the rod is 0.08mm per 30cm.

Dry lubrication coatings is an option on all of the precision produced screws. The application of dry lubrication to lead screws is an effective way of reducing friction, noise, particularly on coarse pitches at high speeds, aswell as enhancing the performance of Turcite X polymer nuts. We can offer a number of surface treatments to ensure wear resistance, even under extreme conditions. Basic dry lubricant enhancement is weather resistant against sunlight, saltwater and cetain chemicals. (Operating temperature range from -250 to +285 C)

Abssac is in the unique position of being able to research and develop special types of thread forms that meet your exact requirements. We are capable of making tooling if a special thread form with a specific lead (or pitch) if required. We are also capable of assisting you with a leadscrew assembly design and provide first article inspection for your approval. Abssac’s engineering staff will provide you with important concepts to optimise the design phase of your product. We offer a Precision thread rolling service. If our standard thread styles and forms do not quite fit what you are looking for, we can provide a thread form that exactly fits your specification. Most common thread forms are the acme or trapezoidal but Abssac can also supply multi-start or special thread profile requirements. The engineering department welcomes enquiries for special and exotic thread forms can provide first article inspection certification if required.

When you want a more sophisticated nut design the chances are the part has more importance in the workings of the machine. By supplying both the screw and nut from the one source, Abssac Limited can eliminate this area of potential trouble. The designer can also utilise the experience of Abssac's engineers to incorporate many features into the nut design in complete confidence. To date many bespoke nut designs have been supplied, including optical mounts, cams, external threads, mounting holes, pulley grooves, tangs and linear guides to name a few. Lead screw sizes range from 1mm diameter up to 100mm with a wide range of both metric and imperial leads per diameter. Nuts can be manufactured in just about any machinable material including Bronze, steels and advanced plastics such as Delrin, PTFE or Turcite. We have recently supplied a bespoke nut design for an engraving machine manufacturer who required a Turcite nut design to incorporate a square rigid body, 6 locating holes of differing diameter and a linear guide slot on the traversing head.

ABSSAC is well known for its quality power screws ranging from about 16mm up to 200mm in diameter, but an often little known side of the company is its capability to supply precision miniature cold rolled formed lead screws and nuts. When dealing with screw diameters from 2mm up to 6mm the key is in the manufacturing technique to ensure thread integrity and lead accuracy. Applications are numerous and Abssac has found its products being supplied to different markets such as medical, defence and robotics around the world. In each case, whether it is a single start or multi helix thread form, linear run out and concentricity of the thread is maintained to a precision classification. Miniature lead screws have been supplied in both Steel and Stainless Steel and on some occasions in plastics.

Matching the screw to a suitable nut is also taken care of by the knowledgeable application engineers at Abssac who ensure performance orientated nut designs at competitive costs. Miniature lead screw applications require smooth operation and low frictional drag due to physically smaller drives with torque limitations. Ensuring the fit between the nut and screw threads is of paramount importance as any small errors in these areas can lead to torque spikes during operation. Then finally you look at how to attach the nut to the application. Can we add tangs, levers, external threads etc. to make the part do more. The next time you have a miniature application that requires the translation of rotary input to linear output then perhaps give Abssac a call.

Passivation is an option on all of the precision produced screws

Generally speaking, passivation is the process of making a material passive or inert in relation to another material prior to using the materials together. The primary purpose of passivation for leadscrews is to remove surface contamination such as iron particles that can foster rust and corrosion. The thread rolling dies and cutting tools can impart these contaminants and should be removed for optimal longevity and service life of your leadscrews. Passivation Benefits includes

Maximizing corrosion resistance, dissolving contaminates from metals. and enhancing the surface appearance. The process can also removes impregnated metals out of thread form.

Electropolishing is an option on all of the precision produced screws

Electropolishing, sometimes called reverse electroplating, prepares metals for plating, anodizing or conversion coating and improves surfaces for use in sterilization. The metal work piece is immersed in a temperature controlled bath of electrolyte and connected to the positive terminal (anode) of a DC power supply. The negative terminal is attached to a cathode to which the particles removed from the anode (the work piece) are attracted when electric current is applied. Often, the size, position and distance of the cathode to the work piece is controlled during the process in order to achieve the desired level of polish and to localize areas of polish. Electropolishing Benefits include, an improved appearance and reflectivity as well as an improved resistance to corrosion. The process can also be used prepare metals for plating, anodizing or conversion coating as well as the removal of edge burrs produced by mechanical cutting tools. Importantly the process removes the stressed and disturbed layer of surface metal caused by cutting, shearing, and tearing action of mechanical stock removal and abrasive finishing. Other advantages include the removal of excess material as desired for milling metal parts. Lastly the process vastly Improves surfaces for use in sterilization in the pharmaceutical industry, surgical equipment, dairy and food handling equipment.

Multiple Piece Lead Screws – Product designs that comprise several components.

Multiple Component Lead Nuts – Custom drive nut assemblies in plastics or metals.

Cross and End Pins

Complete sub-assemblies

Press and Slip Fits

Hand Fitting and Lapping

Bearing Installation

Glue Application

Thread Locker Application

Auxiliary Assemblies

Fastener Installation

Sealing and Packaging

Custom Leadscrew and nut features supplied in the past have included

End Journals

Threaded Journals

Flats

Slots

Keyways

Chamfers

Tapers

Cross Holes

End Holes

Internal Threads

Bearing Reliefs

Snap Ring Grooves

E Clip Grooves

Full Radius Ends

We offer manufacturing services for complete turn-key lead screw assemblies to your specifications. Precision CNC machining services transform our standard thread products into your proprietary designs. Let us optimise the function of your leadscrew product by having your engineering department collaborate with Abssac during the design phase of your linear motion application.We also welcome replication work. You may have an old acme screw that needs replacing but have no technical drawing specifications to work from.

The following sizes are standard Metric thread sizes that are often stocked at ABSSAC.

| Screws | Available Nuts | |||

|---|---|---|---|---|

| Thread Name | Dia. (mm) | Lead (mm) | Matching Simple Nut | Matching Anti-backlash Nut |

| M3 x 0.50 | 3 | 0.5 | • | • |

| M4 x 0.70 | 4 | 0.7 | • | • |

| M5 x 0.80 | 5 | 0.8 | • | • |

| M6 x 1.0 | 6 | 1 | • | • |

| M8 x 1.0 | 8 | 1 | • | • |

| M8 x 1.25 | 8 | 1.25 | • | • |

| M10 X 1.25 | 10 | 1.25 | • | • |

| M10 x 1.50 | 10 | 1.5 | • | • |

| M10 x 2 | 10 | 2 | • | • |

| M10 x 3 | 10.00 | 3.00 | • | • |

| M10 x 5 | 10.00 | 5.00 | • | • |

| M10 x 10 | 10.00 | 10.00 | • | • |

| M10 x 20 | 10.00 | 20.00 | • | • |

| M10 x 35 | 10.00 | 35.00 | • | • |

| M12 x 1.50 | 12 | 1.5 | • | • |

| M12 x 1.75 | 12 | 1.75 | • | • |

| M12 x 3 | 12.00 | 3.00 | • | • |

| M12 x 4 | 12.00 | 4.00 | • | • |

| M12 x 5 | 12.00 | 5.00 | • | • |

| M12 x 6 | 12.00 | 6.00 | • | • |

| M12 x 10 | 12.00 | 10.00 | • | • |

| M12 x 15 | 12.00 | 15.00 | • | • |

| M12 x 25 | 12.00 | 25.00 | • | • |

| M12 x 45 | 12.00 | 45.00 | • | • |

| M14 x 2.0 | 14 | 2 | • | • |

| M16 x 1.50 | 16 | 1.5 | • | • |

| M16 x 2.0 | 16 | 2 | • | • |

| M16 x 4 | 16.00 | 4.00 | • | • |

| M16 x 5 | 16.00 | 5.00 | • | • |

| M16 x 8 | 16.00 | 8.00 | • | • |

| M16 x 16 | 16.00 | 16.00 | • | • |

| M16 x 25 | 16.00 | 25.00 | • | • |

| M16 x 35 | 16.00 | 35.00 | • | • |

| M20 x 4 | 20.00 | 4.00 | • | • |

| M20 x 8 | 20.00 | 8.00 | • | • |

| M20 x 12 | 20.00 | 12.00 | • | • |

| M20 x 16 | 20.00 | 16.00 | • | • |

| M20 x 20 | 20.00 | 20.00 | • | • |

| M20 x 45 | 20.00 | 45.00 | • | • |

| M24 x 5 | 24.00 | 5.00 | • | • |

| Key: • Available | ||||

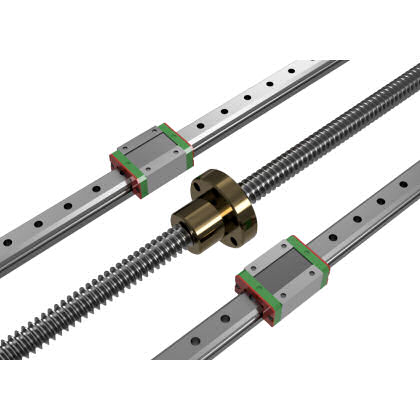

Linear guideways provide excellent load bearing linear motion by re-circulating rolling elements between a profiled rail and a bearing block. By primarily using a four ball path design, within the slide, delivers excellent rigidity and parallelism during operation. The guides can be used in both vertical and horizontal planes.

ABSSAC supplies both radial and thrust bearings, complete with housings, to compliment their expanding lead screw and ball screw ranges. All bearings include the bearing set, bearing housing, snap ring, lock nut, spacer ring and retaining cover. Available to suit all shaft sizes, the range delivers robust radial and thrust protection in any rotary or linear application. Let us help you with your selection.

We provide a full range of quality, low cost lubricants for all our linear products including low vapour pressure greases for clean room and vacuum applications. For example the new Trigel line is specifically formulated to offer a lubrication solution for a wide range of linear motion applications. Please ask for further details.

ABSSAC welcomes reverse engineering applications. Over the years, many customers have sent damaged leadscrews and nuts for us to measure and replicate, often as a result that dimensional drawings do not exist. Please contact one of our knowledgable sales engineers for further details.