| Shaft Dia. (mm) | Lead (mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 5 | 6 | 8 | 9 | 10 | 12 | 15 | 18 | 20 | 24 | 30 | 36 | |

| 4 | D109 | D109 | ||||||||||||

| 6 | D109 | D105 D106 D109 | D105 D106 | D105 D106 D109 | D109 | |||||||||

| 8 | D109 | D105 D106 D109 | D105 D106 | D105 D106 | D105 D106 D109 | D109 | ||||||||

| 10 | D105 D106 D109 | D105 D106 | D105 D106 | D105 D106 D109 | D105 D106 | D109 | ||||||||

| 12 | D105 D106 D109 | D105 D106 | D105 D106 | D109 | D105 D106 | D105 D106 | D109 | |||||||

Note1 ) The numbers in each cell show pages in the catalogue. D105 and D109 are for backlash nut design type, D106 is for the antibacklash nut design.

Accuracy grade and Axial play

Accuracy grade of KSS Resin Lead Screws is based on Japanese Industry Standard Ct10. The tolerance on the specified travel is calculated by

following formula. Axial play is 0.05 to 0.10mm (except Backlash free type).

Tolerance on specified travel ep: ep =±𝓁u300 ×0.21 (mm)

𝓁u : Useful travel (mm)

Material

| Parts | Material |

|---|---|

| Shaft | Stainless Steel 304 or 303 |

| Nut | MC nylon (MC703HL) Mitsubishi Chemical Advanced Materials |

Note 1) Please refer to page D104 for Nut material suitable for special environment.

Note 2) Other nut materials are available on request.

Description of Run-out and location tolerance

Each part of run-out tolerance is based on Japanese Industry Standard Ct10 of Ball Screws.

Thread groove profile

The thread grooves are of a gothic arch design. This is basically the same as those used in the KSS Ball Screw ranges.

Mechanical efficiency

Mechanical efficiency of KSS Resin Lead Screws η(%) can be calculated by the following formula.

The expected “Mechanical efficiency” calculated from measurements is 20%-50%.

Generally, as the Lead increases, “Mechanical efficiency” tends to be high. Please use this number as a reference.

η = Fa×𝓁T × 2 ϖ ×100 (%)

Fa : Axial load(N)

𝓁 : Screw Lead(m)

T : Rotational torque(Nm)

FV value limits on use and endurance data

• FV value limits on use

For KSS Resin Lead Screws, the product of Axial Load and relative velocity of Screw surface is defined as FV, and this definition is reference to check if it is usable or not. Fig. D-11 is maximum FV which can be operated without lubricants in case of using Nut material MRH (Material : MC703HL). Applying lubricants will improve operational efficiency.

Fig. D-11 : FV value limits

Model : MRH0805 / Lubricant : None

Evaluation :

◎ Stable operational conditions were maintained for the long term.

◯ Operation were good, but some wears were seen on the Nuts.

△ Operations became difficult in a relatively short time.

╳ Operations became difficult in the short time.

In case of FV<5(N·m/s), stable operations were maintained.

Operations under FV>10 (N·m/s), maintaining stability was difficult.

Axial Load should be treated more carefully as to upper limits

rather than relative speed.

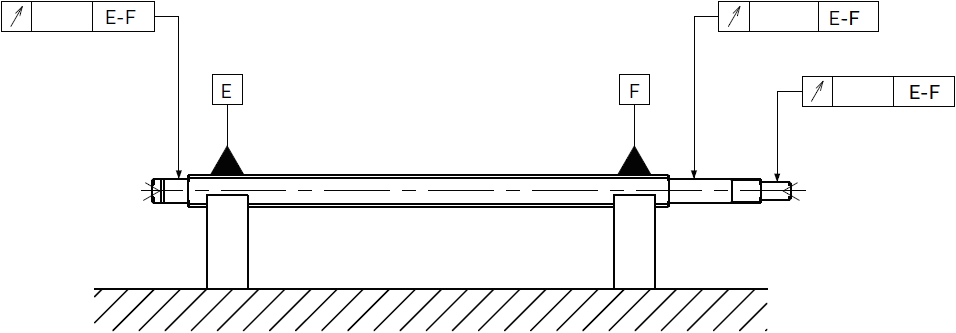

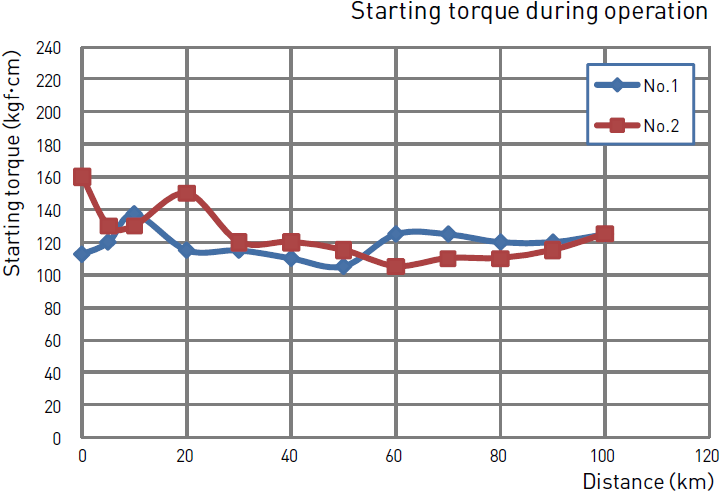

• Endurance test data of Preloaded products(BP2 type)

Model : ø10mm、Lead = 6mm

Load : None

Speed : 1000rpm

Travel : 400mm(bi-directional)

Lubricant : None

Result : After running 100km, operation were good

Starting Torque monitor : see diagram below

Special products

The standard material of the nut is MC nylon(MC703HL), but we also provide with the following nut materials, detailed in the chart below.

Higher volume applications can take advantage of nuts manufactured by injection molding as well as a selection of materials.

Table D-12 : Product performance comparison

| Parts | MRH | MRS | MRE | MRZ | ||

|---|---|---|---|---|---|---|

| Classification | Standard | Customised | Customised | Customised | ||

| Operating environment | Standard environment | Standard environment | Standard environment | Special environment | ||

| Nut appearance |  |  |  |  | ||

| Material | Polyamide resin type | Polyamide resin type | Polyamide resin type | Polyether ether ketone type | ||

| Features | Balanced performance | Balanced performance | Balanced performance | Flame resistance, heat/water resistance | ||

| Other | Good C of E | - | Good electrical conductivity | Food hygiene, chemical resistance | ||

| Mechanical strength | ◯ | ◯ | ◯ | ◎ | ||

| Heat resistance | ◯ | ◯ | ◯ | ◎ | ||

| Wear resistance | ◎ | ◎ | ◎ | ◯ | ||

| Chemical resistance | ◯ | ◯ | ◯ | ◎ | ||

| Machinability | ◎ | ◎ | ◎ | ◯ | ||