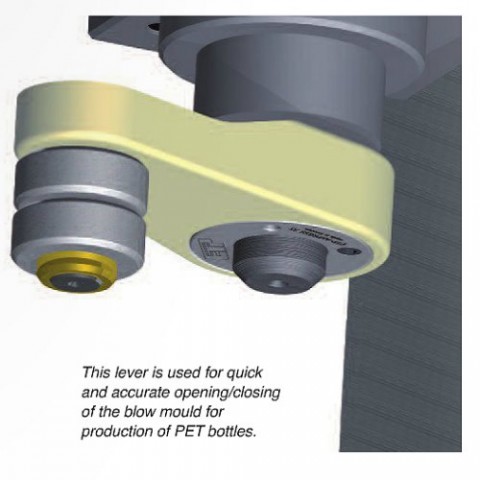

Using the wealth of product and expert engineering knowledge has resulted in the integration of the ETP product principle into many new and interesting applications. In short we are able to offer customised solutions in co-operation with OEM’s. This can be from a small adaptation to a standard part right through to completely bespoke designs that turn your your clamping challenges into innovative and reliable solutions.

As with the standard program, All ETP products consist of a double-walled hardened steel (in some cases stainless steel) sleeve, filled with a pressure medium. In the product flange there are one or more screws and a piston with seals for the pressure setting. When the pressure screw is tightened an even and moderately high surface pressure is created against the shaft and hub, causing the locking effect. The self-contained product allows this procedure to be repeated many times. Whether the hubs are to be removed or repositioned, mounting and dismantling is done in less than a few seconds. The hydraulic principle gives immediate advantages for todays modern machines. The compact designs also ensure better concentricity and balance at increased machine speeds, shorter downtime for service and increased precision.

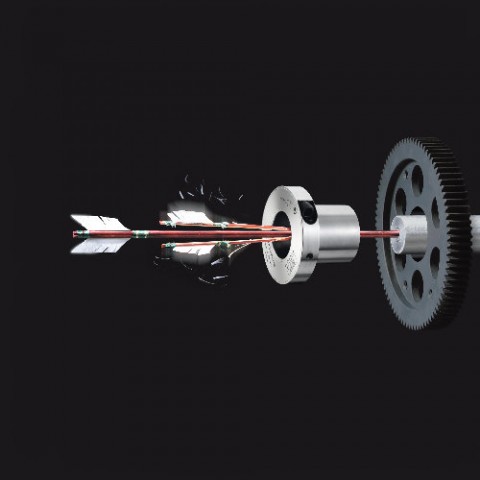

An excellent example of our specialist capability is displayed in the development of the axial tensioner ETP-UNIGRIP which was developed to be used within a packaging machine. The application was to secure circular cutting knives which where originally held in place with spacers and multi-bolt mechanical shaft clamping devices. The mechanical method employed prior to the ETP UNIGRIP was both incredibly time consuming and required a high degree of skilled maintenance to ensure correct cutting blade position.

An excellent example of our specialist capability is displayed in the development of the axial tensioner ETP-UNIGRIP which was developed to be used within a packaging machine. The application was to secure circular cutting knives which where originally held in place with spacers and multi-bolt mechanical shaft clamping devices. The mechanical method employed prior to the ETP UNIGRIP was both incredibly time consuming and required a high degree of skilled maintenance to ensure correct cutting blade position.

The ETP-UNIGRIP was developed to expand three pins axially on the flank of the spacer to ensure continuous axial clamping against a shoulder. The amount of axial movement and force could be accurately adjusted by the rotation of one easily accessed cap screw, whilst another cap screw, again easily accessed, was employed to instigate the shaft clamping, much in a familiar fashion to the standard product ranges, such as the ETP EXPRESS. The integral hydraulic system also reliably delivered an evenly distributed force between the three pistons, offering accurate axial force clamping. The final design therefore used two clamping systems consisting of a hardened steel body with an inner sleeve, three axial pistons with seals and two pressure screws, all in the single piece construction.

Further models have now also been developed that have an internally threaded bore that does not expand and are equipped with with larger, higher force axial thrust pins, with longer piston stroke. The product can also be made to other dimensions on request.

We will be pleased to hear from you regarding your clamping challenges. Please ask for Peter on 01386 421005

ETP Transmission AB has developed and manufactured hydraulic hub-shaft connections for more than 40 years under the brand name ETP. Building up a unique worldwide knowledge and leading position within the hydraulic fastening and centering field. Continuous development with customers, where ETP contribute with wide application knowledge and calculation assistance, has resulted in a steady flow of new products, both standard and customized designs. As you already know - It takes just a few seconds to get perfect centering and fastening of your components when using an ETP. The extremely high precision achieved by using ETP results in minimal runout and unrivalled repeatability. Our customers and worldwide users can confirm what this means in terms of dramatically improved cost-effectiveness.

Real specialists are few and far between. But you do need them. ETP and our local representative have a wide network of highly qualified and experienced technical project employees. This makes us your partners of choice in the search for the right partners for your next project. Our design engineers are deployed in engineering projects in many various sectors such as:

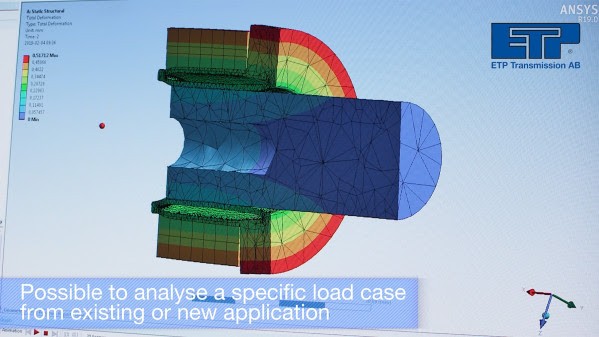

With ANSYS structural analysis software we can solve your complex structural engineering problems and make better and faster design suggestions. With the finite element analysis (FEA) tools available, we can customize and automate solutions for your structural mechanics problems and parameterize them to analyze multiple design scenarios.