|  | ||||

| Abssac Newsletter : Spring 2016 | |||||

Abssac On-The-Go | |||||

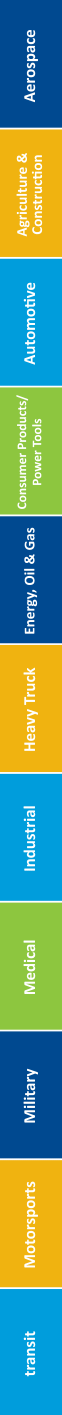

Empowering Products of MW Industries | |||||

In 2016 MW Industries and ABSSAC teamed up in the UK to strengthen the availability of a pedigree range of industrial springs, fasteners, machined parts and flat stamped spring related products. What we like about MW Industries is that they have a hard earned reputation for, and built business on, delivering the most technologically innovative and durable products to a plethora of industries. Mix this with an outstanding depth of product knowledge and the ability to adapt a standard part makes them a winning partner for Abssac. | With broad reaching quality assurance accreditation, MW Industries is one of the world’s premier manufacturers of products that make machines, engines, and complex sub-assemblies work harder, better, longer, and faster. Set us the challenge - Call us to see how Abssac & MW industries products can help solve your industrial challenges. | ||||

The Carbon Spring |  | ||||

Tel: 01386 421005 : Email: sales@abssac.co.uk : Web: www.abssac.co.uk | |||||

Precision miniature motion designsCold rolled formed lead screws are a superb economical solution for linear applications requiring repeatable accuracy and reliability. Using a comprehensive range of screw diameters from 3mm through to 24mm, Abssac can match performance and function by offering the capability to supply custom thread forms and nut designs.

‘We like to pride ourselves at Abssac on our excellent product knowledge for precision miniature motion designs, which are not only excellent quality but also competitively priced.’ Low Cost Linear SolutionAt Abssac we are constantly investigating ways in order to make linear solutions more affordable to our customers. | Rugged Budgetbeam solves tough motion control applications

The Budgetbeam flexible shaft coupling comes from the originators of the helical beam coupling concept over 50 years ago. It is fair to say that we know what we are doing and ensure that each part works with confident reliability. Excellent torque capacity, low weight, high torsional stiffness and inertia makes the coupling ideal for electric motor, servomotor or positional feed back systems. | |

One method is to employ plastic moulding injection techniques for the lead screw nut body. Then instead of machining the screw we look at cold rolled precision. Both methods significantly reduce unit cost and as shown in the image has no detriment to form and function. The lead screw shown is a cold rolled formed 7 start, Stainless Steel screw with a lead accuracy of .25mm per 300mm of travel. (14TPI .250inch diameter .500inch lead). If you currently use lead screw and nut combinations with your application why not give us the chance to prove our affordable solutions. |  With its single piece construction fitting the shaft coupling to the shaft could not be easier thanks to the unique integral clamping arrangement or set screw designs. Available in Aluminium as standard, the Budgetbeam shaft coupling can accept up to 5 degrees of angular and 0.1mm of parallel shaft misalignment. Stocked in metric bores from 4mm, 5mm, 6mm, 7mm, 8mm, 10mm to 12mm. | |

| Schmidt Offset Couplings aid in the manufacture of wind turbine bladesUsed to drive the rubber pull rollers and heated laminating rollers that create a structural adhesive for the manufacture of pre-impregnated composite fibres. During the manufacture of the wind turbine blades, the parallel distance between the driven rollers and motor are constantly adapting to the changing thickness of material substrate. The Schmidt Coupling allows this dynamic offset whilst maintaining constant velocity torque transmission. |

Tel: 01386 421005 : Email: sales@abssac.co.uk : Web: www.abssac.co.uk | |

Pascal discovered the principle. | ||

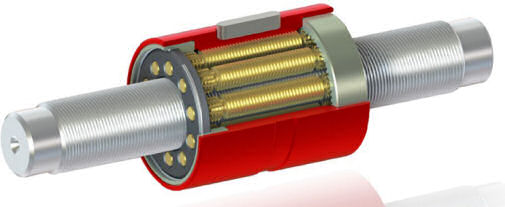

Pascal’s law or the principle of transmission of fluid-pressure states that , ”pressure exerted anywhere in a confined incompressible fluid is transmitted equally in all directions throughout the fluid such that the pressure ratio (initial difference) remains the same”. The ETP product utilises the many positive qualities of this principle and has continued to develop it further so that it can be utilised reliably and accurately within industrial applications. | All ETP products consist of a double-walled hardened steel (in some cases stainless steel) sleeve, filled with a pressure medium. In the product flange there are one or more screws and a piston with seals for the pressure setting. When the pressure screw is tightened an even and moderately high surface pressure is created against the shaft and hub, causing the locking effect. The self-contained product allows this procedure to be repeated many times. Whether the hubs are to be removed or repositioned, mounting and dismantling is done in less than a few seconds. The hydraulic principle gives immediate advantages for today's modern machines. The compact designs also ensure better concentricity and balance at increased machine speeds, shorter downtime for service and increased precision. The ETP products are available through Abssac Limited. |  |

Probably the largest ball screw range in the UKAbssac’s precision rolled ball screws can be supplied in Stainless Steel and hardened Steel with lead accuracies of 50 microns over 300mm and 20 micron backlash. Our precision ball screws have operational tolerances comparable to more expensive ground ball screw assemblies, but at much less cost. Using precision ground ballnuts running on precision rolled screws, means that our lead accuracy is close to precision ground screws. All products are backed up with a quality assurance of ISO9001 and of course Abssac’s 30 years of ball screw experience. The standard ball screw products are available in non machined end form, or machined to specific end detail requirements. A full machining capability provides the peace of mind that each end journal is supplied to the highest accuracy. The parts can be delivered in short lead times, ready to fit. Standard outside diameters range from 4mm to 15mm with leads from 1mm to 20mm. The product range also includes flanges, “If you are retrofitting or specifying ball screws within an application then please give us a call. We have the knowledge and product range to help choose the right part and most importantly within budget” Tel: 01386 421005 : Email: sales@abssac.co.uk | ||

|     Are you connecting a motor to a pump ?Consider the Sure-Flex® flexible shaft coupling range available from Abssac, which was designed specifically with that industry in mind. With large stocks kept, we offer an excellent solution to your pump coupling requirements The easy to fit Sure-Flex® elastomeric shaft couplings rely on a proven element produced from a elastic polymer, to absorb the shaft misalignments but also transmit torque whilst simultaneously dealing with shock and vibration. Sure-Flex® shaft couplings can be installed quickly and easily because there are no bolts, gaskets, covers or seals. Alignment can be checked with a straight edge placed across the outside of the precision machined flanges. No special tools are needed for installation, alignment or removal. No lubrication, trouble free operation.... The teeth of the sleeve lock into the teeth of the flanges without clamps or screws, tightening under torque to provide smooth transmission of power. Since there is no rubbing action of metal against rubber to cause wear, the couplings are not affected by abrasives, dirt or moisture. This eliminates the need for lubrication or maintenance, whilst providing clean dependable, quiet performance. The De Montfort School Sponsorship 2016 News

ABSSAC continues the sponsorship of the TDMS Robotics club at The De Montfort School and wishes them luck with preparations for the next regional event. The teams are busy tweaking with their robots to ensure they are in optimum condition for the competition. With one robot already qualified for the Nationals after attending another regional qualification event, this is the chance to improve strategy and refine the minor details of this robot. Let' get the second robot to the Nationals ! Come on TDMS Robotics club, you can do it........ |

Sometimes an application can benefit from a little flexibility. | |

One of the greatest advantages of the Helical flexure beam product is in its ability to adapt into applications where simply others can not follow. By altering the characteristics of the coiled beam area, torque capacity, angular and parallel misalignment capabilities, (torsional and lateral bending rates of flexured u-joints) can be modified to suit specific specifications and or requirements. Up to 90 degrees of angular offset can be achieved in the one piece design. Once the performance dynamics of the beam area are decided, we then look at the way the shaft coupling attaches in the application or perhaps how we can add other parts of the total mechanism into the single piece shaft coupling. Add to the mix a choice of just about any type of machineable material and the product is a complete game changer when it comes to shaft connection. | |

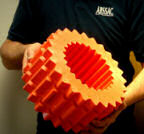

More Thrust in 20164 x the thrust to be correct. The satellite roller screw is used to transform rotary movements into linear movements or vice versa. Using precision, load bearing, rollers instead of ball bearings in the nut housing can achieve incredible accuracy and longevity of service. The captivated rollers are constantly engaged with the threads of the screw which results in a high number of contact points between the screw and nut therefore allowing greater axial load capacity. Offering a full custom machining capability, ABSSAC has supplied ground format satellite roller screws for well over 30 years, where expertise and product knowledge has allowed the product to be used within numerous critical applications. Applications have been as diverse as replacing the hydraulic legs on flight simulators to zero backlash 10x1 preloaded G1 (6microns per 300mm lead accuracy) accuracy roller screws used above earth’s atmosphere. The satellite roller screw product can definitely take linear challenges to the next level. By offering high load capacity, reliability and acute accuracy a roller screw design will always transmit more load than a ball screw nut assembly size for size. If an application requires a high linear load to be repeatedly moved at speed but the design is constrained by space, the satellite roller screw program is ideal. If you are designing a linear system maybe it’s worth having a look at this truly capable product. | |

Tel: 01386 421005 : Email: sales@abssac.co.uk : Web: www.abssac.co.uk | |

Whether it is a fine or coarse pitch thread, the end result is a high integrity lead screw and nut product that is ready to be fitted directly into the application and perform.

Whether it is a fine or coarse pitch thread, the end result is a high integrity lead screw and nut product that is ready to be fitted directly into the application and perform.