| |

| Abssac Newsletter : April 2015 | |

Abssac On-The-Go | |

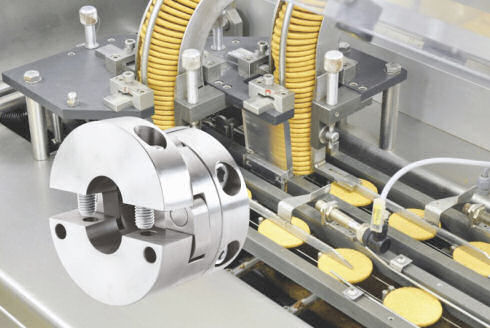

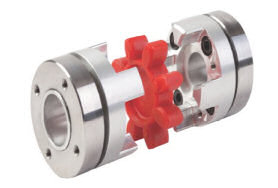

POWER SCREWS | Solid Compression couplings in stockA solid compression-type coupling or rigid coupling as it is sometimes termed has no flexibility but can effectively be used to connect two shafts to make a permanent joint. The solid coupling is usually designed to be capable of transmitting the full torque load capacity of the shaft. By precisely aligning the two shafts and holding them firmly in place, rigid couplings help to maximize performance and increase the expected life of the machine. These rigid couplings are available in two basic designs to fit the needs of different applications. Sleeve-style couplings are the most affordable and easiest to use, whilst clamped or compression rigid couplings come in two parts and fit together around the shafts to form a sleeve. Both types are available ex stock from Abssac to suit shaft sizes from 6mm up to 50mm in diameter.”

| |

With all of our customers, Abssac strives to keep them Abssac is the place to come for fast delivery, keen prices and knowledgeable sales | ||

Continuously stocking up to 3 meter lengths | ||

Additionally, | ||

Call Phil Jones on 01386 421005 and be as

| ||

ETP-UNIGRIP - A unique development in shaft clamping | ||

An excellent example of our specialist capability is displayed in the development of the axial tensioner ETP-UNIGRIP which was developed to be used within a packaging machine. | The application was to secure circular cutting knives which where originally held in place with spacers and multi-bolt mechanical shaft clamping devices. The mechanical method employed prior to the ETP UNIGRIP was both incredibly time consuming and required a high degree of skilled maintenance to ensure correct cutting blade position. The ETP-UNIGRIP was developed to expand three pins axially on the flank of the spacer to ensure continuous axial clamping against a shoulder. The amount of axial movement and force could be accurately adjusted by the rotation of one easily accessed cap screw, whilst another cap screw, again easily accessed, was employed to instigate the shaft clamping, much in a familiar fashion to the standard product ranges, such as the ETP EXPRESS. The integral hydraulic system | also reliably delivered an evenly distributed force between the three pistons, offering accurate axial force clamping. The final design therefore used two clamping systems consisting of a hardened steel body with an inner sleeve, three axial pistons with seals and two pressure screws, all in the single piece construction. Further models have now also been developed that have an internally threaded bore that does not expand and are equipped with with larger, higher force axial thrust pins, with longer piston stroke. The product can also be made to other dimensions on request. We will be pleased to hear from you regarding your clamping challenges. Please ask for Peter or Chris on |

Stainless steel shaft couplings meet the needs of specific sector applications. | |

Shaft Couplings used within determined industries sometime call for customised materials to be compliant with special regulations and requirements. Examples of this include packaging machines for the food and pharmaceutical industries well as coating machinery under vacuum conditions. In such industries, the choice of high grade steel is adapted to the respective customer requirements. Many industries require the use of Stainless steel and the Schmidt-Kupplung product portfolio can meet this challenge across the majority of its product range. Precision, high displacement and compact designFor example, within the food-processing industry it is common to see shaft couplings being utilised in many areas of the driven part of the machine. The working axial area available for installation can often be very minimal. There can also be the case where the driven shaft coupling comes into direct contact with the food substrate. Mechanically, the shaft coupling must deliver reliable precision torque transmission, high torsional stiffness, axial shaft displacement and ease of fitting, these are typical application demands. In this scenario the Schmidt-Kupplung range can offer a stainless steel solution called the Semiflex Compact Plus Type C320 with split clamp hubs. By using a split clamp hub solution there is no need to axially shift any bordering components of the machine during installation. Additionally, the specific hygiene requirements can be met by using a high grade 1.4301 stainless steel for its construction. The torsionally stiff coupling, with an outer diameter of 120 mm, has a nominal torque of 316 Nm (maximum torque 330 Nm) and a radial displacement capacity of 3 mm, according to torque and displacement requirements. What makes the shaft coupling unique is the transmission of the rotary motion and torque takes place in the coupling through two pairs of parallel links arranged at 90° to each other. They connect the driving side and the power take-off with the centre disc. |

The lateral displacement compensation takes place through a swivelling movement of the needle bearing parallel link rods on the connecting bolts that are located in the internal discs. Innovatively, synchronisation between driver and driven ends is therefore guaranteed despite the high displacement. Installation of the coupling, which is already designed to be very compact, is made easy with an overall length of only 88 mm. To meet the stringent regulations for machines that come into contact with food fit for human consumption, the needle bearings are equipped with food-grade grease. In other cases food legislation compliant slide bearings can be used. Similar coupling solutions are also applicable to packaging machines for the pharmaceutical sector and bottling plants. To some extent it was these industries that pioneered the use of 1.4501 stainless steel. Likewise other Schmidt couplings or indeed coupling components such as coupling links are made out of 1.4541 and 1.4571 premium steel. |

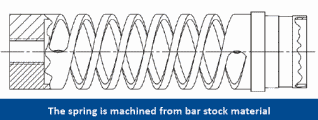

| Compression spring machined from a solid piece of material. | |

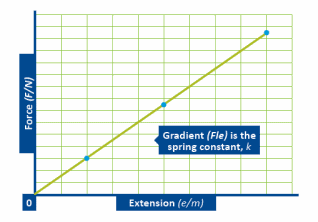

In classical physics, a spring is seen as a device that stores potential energy, specifically elastic potential energy. Back in the 17th century the British physicist Robert Hooke developed what was to become known as Hooke’s law of elasticity. This states that the extension of an elastic rod (its distended length minus its relaxed length) is linearly proportional to its tension, the force used to stretch it. Similarly, the contraction (negative extension) is proportional to the compression (negative tension).

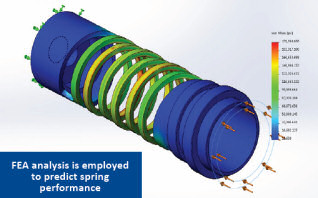

This accuracy of spring rate is more or less impossible to achieve with a wound spring but is readily available in the machined spring format. All spring forms adhere to this law, however it is the linear accuracy of the relationship between the compression or extension to the force applied, that separates the traditional wire wound spring from the machined spring. As the name suggests, the product is machined from a single piece of bar stock material rather than coiling wire. Due to the geometry of the machined coil, the spring rate is extremely linear in compression and extension. In fact spring rate tolerance can be as good as +/- 1% if required.

So why use machined springs? Two main advantages are immediately apparent. Machined springs can provide very precise, linear deflection rates because virtually all- | residual stresses are eliminated. Secondly, the machined spring also enables the designer to incorporate the way in which the spring attaches into the single piece design, often incorporating parts of the spring assembly into the single part construction. Why are machined springs so unique? Quite simply, it is possible to have one, two, three of more spring coil elements in the single piece spring construction.

Multi-start springs deliver outstanding performance advantages, since the independent helixes are in the same cylindrical plane, which provides totally enhanced spring performance. In fact, the machined multiple start spring coil configurations takes the performance and reliability to levels simply not achievable by the traditional wound spring format. So why use machined Compression or Extension springs? A single start spring provides a reaction force plus a moment. On multiple start springs, virtually all internal moments are resolved within the spring itself, which translates into excellent compression or extension parallelism. The machined spring product has proven itself in medical, aerospace, semiconductor and motor-sport industries to name a few. Wherever a wound spring is not able to meet your performance criteria or a new spring design requires accuracy and repeatability, the machined spring is the ideal partner. The next time you require a spring in a critical or high duty cycle environment, the machined spring from Abssac Limited may be the answer to your design problems.

| |

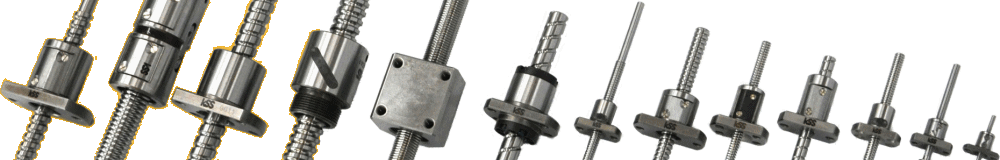

Have you heard?Abssac’s precision rolled ball screws can be supplied in Stainless Steel and hardened Steel with lead accuracies of 50 microns over 300mm and 20 micron backlash. Our precision ball screws have operational tolerances comparable to more expensive ground ball screw assemblies, but at much less cost. Using precision ground ballnuts running on precision rolled screws, means that our lead accuracy is close to precision ground screws. All products are backed up with a quality assurance of ISO9002 and of course Abssac’s 30 years of ball screw experience. The standard ball screw products are available in non machined end form, or machined to specific end detail requirements. A full machining capability provides a service for complete end journal completion to the highest accuracy. The parts can be delivered in short lead times ready to fit. Standard outside diameters range from 4mm to 15mm with leads from 1mm to 20mm. The product range also includes flanges, pillow block bearings and synthetic greases. Phil Jones at Abssac says. “If you are retrofitting or specifying ball screws within an application then please give us a call. We have the knowledge and product range to help choose the right part and most importantly within budget” | ||

| ||

| ||

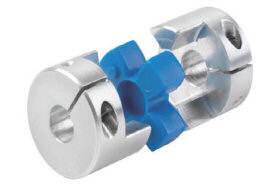

| Jaw dropping pricesThe Jaw style shaft couplings from Abssac are a low cost, no fuss flexible shaft connection... The curved jaw coupling design consists of an elastic ‘spider’ and two hubs. The spider utilises advanced polyurethane materials to provide reliable torque transmission as well dampening of impulse loads. With a selection of spider to choose from allows the user to customise the jaw coupling’s performance. Selecting a soft spider material will give the jaw coupling the greatest dampening characteristics, whilst a hard spider will provide the greatest torque capacity. Hubs are available in cast Iron or Aluminium and all hub sizes are stocked with bore and keyways to suit shaft sizes from 6mm to 60mm (Or pilot bored). The Jaw couplings are rated from 10Nm up to 665Nm and are a direct replacement to other industrial jaw couplings. Larger sizes are available on request. Why not give Stacey a call to ensure correct product selection. Abssac Limited Tel: +44 (0)1386 421005

| ||

| SponsorshipAbssac is proud to be able to sponsor Tom Biggs at Worcester Warriors rugby club. He has played for England Saxons, and has scored 32 tries in 127 Premiership appearances for Leeds Carnegie, Newcastle Falcons and Bath. Abssac’s precision products and Tom’s dynamic performance is considered an excellent match and we wish him continued success through the 2015 season. | UK Semi-finalists!Abssac is continuing to sponsor the The De Montford School in Evesham and their robotics club - TDMS ROBOTICS. In 2014, three teams “Tolerance, Tangent and Titan” entered the second national competition and all three teams made it to the semi-finals! We hope to be finalists in the next game VEX Skyrise 2015 - http://team5638.co.uk/

| |

Precision Edge Welded Bellows | |||

Do you use precision edge welded bellows ? Abssac is now supplying a range of custom designed bellows, through Bellows Tech, LLC who specialize in the design and manufacture of precision edge welded bellows and assemblies. The product encompasses, a wide array of alloys including Inconel, Hastelloy, Titanium, Aluminium and 316L stainless steel. | High Vacuum • Semiconductor • Aerospace The metal bellows provide a hermetic, all-metal pressure barrier and seal, that can flex in one or more direction. A key advantage being that the bellows can provide the most flexibility in the smallest amount of available space. The flexible metal barrier, that edge welded bellows provide, can be put to use in many different ways to perform a variety of functions. For example, applications that require high quality, state-of-the-art micro fusion joining; edge welded bellows are very functional and cost effective. For further details please contact our technical sales department on | ||

Budgetbeam - precision shaft coupling connection | |||

Budgetbeam is a brand new flexible shaft coupling addressing the requirement for a high torsional stiffness, low cost in a single piece construction. It is ideal for applications where zero backlash and constant velocity torque transmission is required. Abssac revised the basic helical beam style shaft coupling and has achieved extraordinary parameters with the new double start helical beam design. As standard all Budgetbeam models compensate for the three major shaft misalignments of angular, parallel and skewed offsets unlike lesser shaft couplings. Since the design has two equidistant flexible helical beams elements with the design, the product has excellent rational balance. Maximum rpm is rated at a staggering 10,000rpm as standard. The Budgetbeam shaft coupling is manufactured from low inertia aluminium and available in set screw or unique integral clamp shaft configuration. There are four basic blank sizes which are delivered in straight through bore diameters from 3mm to 12mm. Ideal applications include encoder, resolver, | stepper motor and small electric motor axis drives. Most importantly, by employing new production techniques allows the Budgetbeam to offer all these advantages at an extremely competitive price. The Budgetbeam expects to go head to head with other beam, bellows or x-slot shaft coupling designs on performance, price and delivery. All budgetbeam products are also quality assured by the latest BS EN ISO9001: 2000 standard. | ||

Tel: 01386 421005 : Email: sales@abssac.co.uk : Web: www.abssac.co.uk | |||