Bronze nuts available in flanged

and threaded mount designs as standard.

Matching leads in both right and left hand formats

are available.

Custom design.

We offer a complete design service.

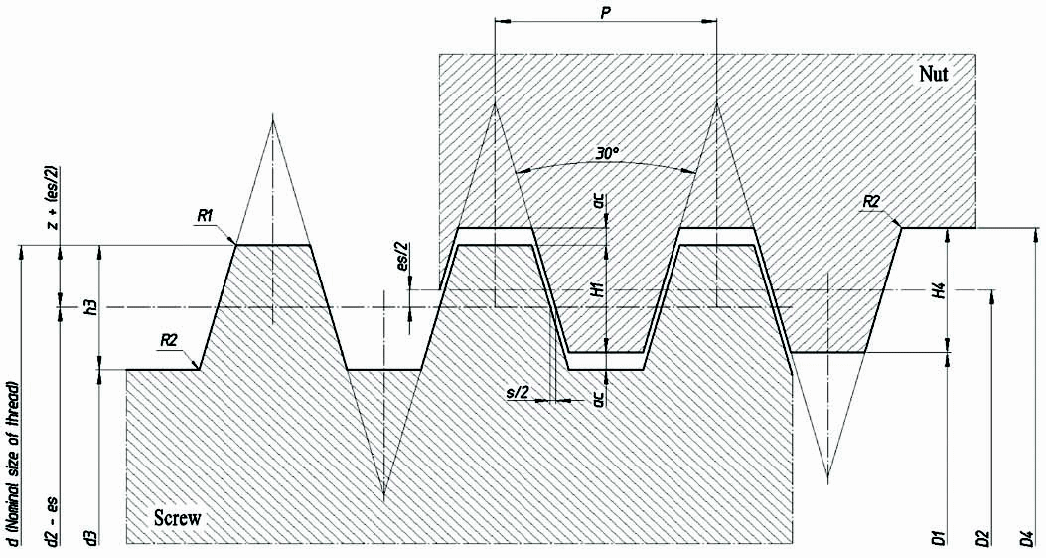

H1 = 0.5 P

h3 = H4 = H1 + ac = 0.5 P + ac

z = 0.25 P = H1/2

d3 = d 2 h3

d2 = D2 = d 2 z = d 0.5 P

D2 = d + 2 ac

ac = bottom play

es = top deviation for screw

s = 0.26795 es

R1 max. = 0.5 ac

R2 max. = ac

| Screw | Lead Accuracy mm/mm | Material | Grade | Page |

|---|---|---|---|---|

| Single Start sizes | 5 | |||

| Multi Start sizes | 6 | |||

| Nut Types | 78 | |||

| Single Start TRC45 | .1/100 | Carbon Steel | EN 100832 1C45 1.0503 | 910 |

| Single Start TRC15 | .2/200 | Carbon Steel | EN 10084 C15E 1.1141 | 11 |

| Multi Start TRC15 | .2/200 | Carbon Steel | EN 10084 C15E 1.1141 | 12 |

| Single Start TR304 | .2/200 | Stainless Steel | INOX A2 AISI 304 1.4301 | 13 |

| Multi Start TR304 | .2/200 | Stainless Steel | INOX A2 AISI 304 1.4301 | 14 |

| Single Start TR316 | .2/200 | Stainless Steel | INOX A4 AISI 316 1.4401 | 15 |

| Nut | Shape | Material | Grade | |

| FBN | Flanged | Bronze | EN 1982 CuSn5Zn5Pb5C CC491K | 16 |

| OFBN | Flanged | Bronze | EN 1982 CuSn12C CC483K | 19 |

| FBNNS | Flanged | Bronze | EN 1982 CuSn5Zn5Pb5C CC491K | 22 |

| FBNEL | Flanged | Bronze | EN 1982 CuSn12C CC483K | 25 |

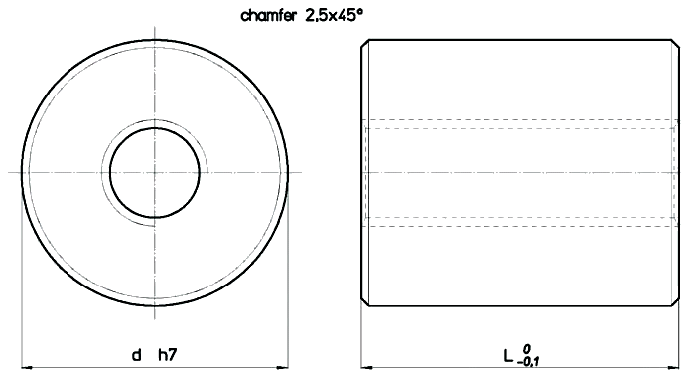

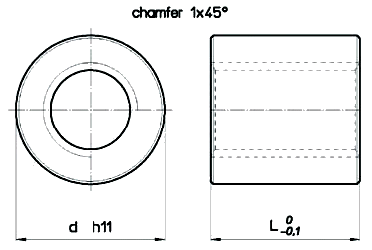

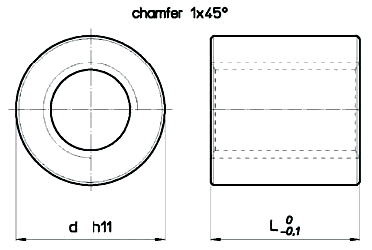

| RBND | Cylindrical | Bronze | EN 1982 CuSn5Zn5Pb5C CC491K | 28 |

| RBN | Cylindrical | Bronze | EN 1982 CuSn7Zn4Pb7C CC493K | 28 |

| LRBN | Cylindrical | Bronze | EN 1982 CuSn12C CC483K | 28 |

| RSND | Cylindrical | Steel | EN 102773 11SMnPb37 1.0737 | 29 |

| RSN | Cylindrical | Steel | EN 102773 11SMnPb30 1.0715 | 30 |

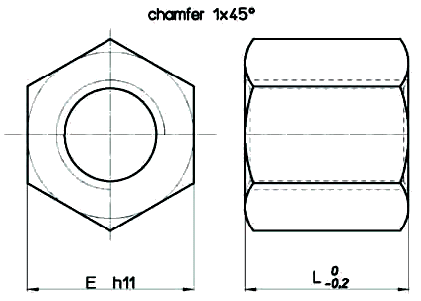

| HSN | Hexagonal | Steel | EN 102773 11SMnPb37 1.0737 | 31 |

| RPN | Cylindrical | Plastic | PA6 + Mo S2 DIN 7728 | 32 |

| FPN | Flanged | Plastic | PA6 + Mo S2 DIN 7728 | 33 |

| HEX | Hexagonal | Steel | EN 102773 11SMnPb37 1.0737 | |

| RSSN | Cylindrical | Stainless Steel | INOX A1 AISI 303 1.4305 | |

| RPN | Cylindrical | Plastic | PA6 + Mo S2 DIN 7728 | |

| Single Start | Carbon Steel | Stainless Steel | ||||||

|---|---|---|---|---|---|---|---|---|

| C45 | C15 | A2 (304) | A4 (316) | |||||

| TRC45 accuracy 0.1mm / 300mm | TRC15 accuracy 0.2mm / 300mm | TR304 accuracy 0.2mm / 300mm | TR316 accuracy 0.2mm / 300mm | |||||

| THREAD | RH | LH | RH | LH | RH | LH | RH | LH |

| Tr 10 x 2 | • | • | • | • | • | • | • | • |

| Tr 10 x 3 | • | • | • | • | • | • | • | • |

| Tr 12 x 3 | • | • | • | • | • | • | • | • |

| Tr 14 x 3 | • | • | • | • | • | • | • | • |

| Tr 14 x 4 | • | • | • | • | • | • | • | • |

| Tr 16 x 4 | • | • | • | • | • | • | • | • |

| Tr 18 x 4 | • | • | • | • | • | • | • | • |

| Tr 20 x 4 | • | • | • | • | • | • | • | • |

| Tr 22 x 5 | • | • | • | • | • | • | • | • |

| Tr 24 x 5 | • | • | • | • | • | • | • | • |

| Tr 25 x 3 | • | • | • | • | • | • | • | • |

| Tr 25 x 5 | • | • | • | • | • | • | • | • |

| Tr 26 x 5 | • | • | • | • | • | • | • | • |

| Tr 28 x 5 | • | • | • | • | • | • | • | • |

| Tr 30 x 3 | • | • | • | • | • | • | • | • |

| Tr 30 x 4 | • | • | • | • | • | • | • | • |

| Tr 30 x 5 | • | • | • | • | • | • | • | • |

| Tr 30 x 6 | • | • | • | • | • | • | • | • |

| Tr 32 x 6 | • | • | • | • | • | • | • | • |

| Tr 35 x 3 | • | • | • | • | • | • | • | • |

| Tr 35 x 4 | • | • | • | • | • | • | • | • |

| Tr 35 x 5 | • | • | • | • | • | • | • | • |

| Tr 35 x 6 | • | • | • | • | • | • | • | • |

| Tr 35 x 8 | • | • | • | • | • | • | • | • |

| Tr 36 x 6 | • | • | • | • | • | • | • | • |

| Tr 40 x 3 | • | • | • | • | • | • | • | • |

| Tr 40 x 4 | • | • | • | • | • | • | • | • |

| Tr 40 x 5 | • | • | • | • | • | • | • | • |

| Tr 40 x 6 | • | • | • | • | • | • | • | • |

| Tr 40 x 7 | • | • | • | • | • | • | • | • |

| Tr 40 x 8 | • | • | • | • | • | • | • | • |

| Tr 40 x 10 | • | • | • | • | • | • | • | • |

| Tr 44 x 7 | • | • | • | • | • | • | • | • |

| Tr 45 x 8 | • | • | • | • | • | • | • | • |

| Tr 50 x 3 | • | • | • | • | • | • | • | • |

| Tr 50 x 4 | • | • | • | • | • | • | • | • |

| Tr 50 x 5 | • | • | • | • | • | • | • | • |

| Tr 50 x 6 | • | • | • | • | • | • | • | • |

| Tr 50 x 8 | • | • | • | • | • | • | • | • |

| Tr 50 x 10 | • | • | • | • | • | • | • | • |

| Tr 55 x 9 | • | • | • | • | • | • | • | • |

| Tr 60 x 6 | • | • | • | • | • | • | • | • |

| Tr 60 x 7 | • | • | • | • | • | • | • | • |

| Tr 60 x 9 | • | • | • | • | • | • | • | • |

| Tr 70 x 10 | • | • | • | • | • | • | • | • |

| Tr 80 x 10 | • | • | • | • | • | • | ||

| Tr 90 x 12 | • | • | • | • | • | • | ||

| Tr 95 x 16 | • | • | • | • | • | • | ||

| Tr 100 x 12 | • | • | • | • | • | • | ||

| Tr 100 x 16 | • | • | • | • | • | • | ||

| Tr 120 x 14 | • | • | • | • | • | • | ||

| Tr 120 x 16 | • | • | • | • | • | • | ||

| Tr 140 x 14 | • | • | • | • | • | • | ||

• Standard Product • Made To Order Only

| Multiple Start | Carbon Steel | Stainless Steel | ||||

|---|---|---|---|---|---|---|

| C15 | C45 | A2 (304) | ||||

| TRC15 accuracy 0.2mm / 300mm | TRC45 accuracy 0.1mm / 300mm | TR304 accuracy 0.2mm / 300mm | ||||

| THREAD | RH | LH | RH | LH | RH | LH |

| Tr 10 x 4 (P2) | • | • | • | • | • | • |

| Tr 12 x 6 (P3) | • | • | • | • | • | • |

| Tr 14 x 6 (P3) | • | • | • | • | • | • |

| Tr 16 x 8 (P4) | • | • | • | • | • | • |

| Tr 18 x 8 (P4) | • | • | • | • | • | • |

| Tr 20 x 8 (P4) | • | • | • | • | • | • |

| Tr 20 x 20 (P5) | • | • | • | • | • | • |

| Tr 22 x 10 (P5) | • | • | • | • | • | • |

| Tr 24 x 10 (P5) | • | • | • | • | • | • |

| Tr 25 x 10 (P5) | • | • | • | • | • | • |

| Tr 25 x 25 (P5) | • | • | • | • | ||

| Tr 26 x 10 (P5) | • | • | • | • | • | • |

| Tr 28 x 10 (P5) | • | • | • | • | • | • |

| Tr 30 x 12 (P6) | • | • | • | • | • | • |

| Tr 30 x 30 (P5) | • | • | • | • | ||

| Tr 32 x 12 (P6) | • | • | • | • | • | • |

| Tr 36 x 12 (P6) | • | • | • | • | • | • |

| Tr 40 x 14 (P7) | • | • | • | • | • | • |

| Tr 40 x 40 (P8) | • | • | • | • | ||

• Standard Product • Made To Order Only

| Single Start | FBN Bronze CuSn5Zn5Pb5-C | OFBN Bronze CuSn12-C | FBNNS Bronze CuSn5Zn5Pb5-C | FBNEL Bronze CuSn12-C | FPN Plastic PA6+MoS2 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

|  |  |  |  | ||||||

| THREAD | RH | LH | RH | LH | RH | LH | RH | LH | RH | LH |

| Tr 10 x 2 | • | • | ||||||||

| Tr 10 x 3 | • | • | • | • | ||||||

| Tr 12 x 3 | • | • | • | • | • | • | • | • | ||

| Tr 14 x 3 | • | • | ||||||||

| Tr 14 x 4 | • | • | • | • | • | • | ||||

| Tr 16 x 4 | • | • | • | • | • | • | • | • | • | • |

| Tr 18 x 4 | • | • | • | • | • | • | • | • | ||

| Tr 20 x 4 | • | • | • | • | • | • | • | • | • | • |

| Tr 22 x 5 | • | • | • | • | • | • | • | • | ||

| Tr 24 x 5 | • | • | • | • | ||||||

| Tr 25 x 3 | • | • | ||||||||

| Tr 25 x 5 | • | • | • | • | • | • | ||||

| Tr 26 x 5 | • | • | • | • | ||||||

| Tr 28 x 5 | • | • | • | • | • | • | • | • | • | • |

| Tr 30 x 3 | • | • | • | • | ||||||

| Tr 30 x 4 | • | • | ||||||||

| Tr 30 x 5 | • | • | ||||||||

| Tr 30 x 6 | • | • | • | • | • | • | • | • | • | • |

| Tr 32 x 6 | • | • | • | • | • | • | ||||

| Tr 35 x 3 | • | • | ||||||||

| Tr 35 x 4 | • | • | ||||||||

| Tr 35 x 5 | • | • | ||||||||

| Tr 35 x 6 | • | • | • | • | • | • | • | • | ||

| Tr 35 x 8 | • | |||||||||

| Tr 36 x 6 | • | • | • | • | ||||||

| Tr 40 x 3 | • | • | ||||||||

| Tr 40 x 4 | • | • | • | |||||||

| Tr 40 x 5 | • | • | ||||||||

| Tr 40 x 6 | • | • | ||||||||

| Tr 40 x 7 | • | • | • | • | • | • | • | • | • | • |

| Tr 40 x 8 | • | |||||||||

| Tr 40 x 10 | • | • | ||||||||

| Tr 44 x 7 | • | • | • | • | ||||||

| Tr 45 x 8 | • | • | • | • | ||||||

| Tr 50 x 3 | • | • | ||||||||

| Tr 50 x 4 | • | • | ||||||||

| Tr 50 x 5 | • | • | ||||||||

| Tr 50 x 6 | • | • | • | |||||||

| Tr 50 x 8 | • | • | • | • | • | • | • | • | • | • |

| Tr 50 x 10 | • | |||||||||

| Tr 55 x 9 | • | • | ||||||||

| Tr 60 x 6 | • | • | ||||||||

| Tr 60 x 7 | • | • | ||||||||

| Tr 60 x 9 | • | • | • | • | • | • | • | • | ||

| Tr 70 x 10 | • | • | • | • | ||||||

| Tr 80 x 10 | • | • | ||||||||

| Tr 90 x 12 | • | • | ||||||||

| Tr 95 x 16 | • | • | ||||||||

| Tr 100 x 12 | • | • | ||||||||

| Tr 100 x 16 | • | • | ||||||||

| Tr 120 x 14 | • | • | ||||||||

| Tr 120 x 16 | • | • | ||||||||

| Tr 140 x 14 | • | • | ||||||||

• Standard Product • Made To Order Only

| Single Start | RBN Bronze CuSn7Zn5Pb7-C | RBND Bronze CuSn5Zn5Pb5-C | RSN Steel 11SMn30 | RSSN Stainless Aisi 303 1.4305 | RPN Plastic PA6+MoS2 | HSN Steel 11SMnPb37 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|  |  |  |  |  | |||||||

| THREAD | RH | LH | RH | LH | RH | LH | RH | LH | RH | LH | RH | LH |

| Tr 10 x 2 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 10 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 12 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 14 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 14 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 16 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 18 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 20 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 22 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 24 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 25 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 25 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 26 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 28 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 30 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 30 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 30 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 30 x 6 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 32 x 6 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 35 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 35 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 35 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 35 x 6 | • | • | • | • | • | • | • | • | • | • | ||

| Tr 35 x 8 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 36 x 6 | • | • | • | • | • | • | • | • | • | • | ||

| Tr 40 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 40 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 40 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 40 x 6 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 40 x 7 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 40 x 8 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 40 x 10 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 44 x 7 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 45 x 8 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 50 x 3 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 50 x 4 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 50 x 5 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 50 x 6 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 50 x 8 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 50 x 10 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 55 x 9 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 60 x 6 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 60 x 7 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 60 x 9 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 70 x 10 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 80 x 10 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 90 x 12 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 95 x 16 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 100 x 12 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 100 x 16 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 120 x 14 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 120 x 16 | • | • | • | • | • | • | • | • | • | • | • | • |

| Tr 140 x 14 | • | • | • | • | • | • | • | • | • | • | • | • |

• Standard Product • Made To Order Only

| Stock no. for screw RIGHT | Stock no. for screw LEFT | Diameter x Lead | Thread Starts | Lead Accuracy μm/300mm | Straightness mm/mm | Weight kg/mt |

|---|---|---|---|---|---|---|

| • TRC45 10 T R • TRC45 10 A R • TRC45 12 A R | • TRC45 10 T L • TRC45 10 A L • TRC45 12 A L | Tr 10 x 2 Tr 10 x 3 Tr 12 x 3 | 1 1 1 | 100 100 100 | 0.5 / 300 0.5 / 300 0.5 / 300 | 0.48 0.42 0.65 |

| • TRC45 14 R R • TRC45 14 A R • TRC45 16 A R • TRC45 18 A R | • TRC45 14 R L • TRC45 14 A L • TRC45 16 A L • TRC45 18 A L | Tr 14 x 3 Tr 14 x 4 Tr 16 x 4 Tr 18 x 4 | 1 1 1 1 | 100 100 100 100 | 0.5 / 300 0.5 / 300 0.5 / 300 0.5 / 300 | 0.93 0.86 1.17 1.53 |

| • TRC45 20 A R • TRC45 22 A R • TRC45 24 A R | • TRC45 20 A L • TRC45 22 A L • TRC45 24 A L | Tr 20 x 4 Tr 22 x 5 Tr 24 x 5 | 1 1 1 | 100 100 100 | 0.5 / 300 0.5 / 300 0.5 / 300 | 1.94 2.29 2.78 |

| • TRC45 25 R R • TRC45 25 A R • TRC45 26 A R • TRC45 28 A R | • TRC45 25 R L • TRC45 25 A L • TRC45 26 A L • TRC45 28 A L | Tr 25 x 3 Tr 25 x 5 Tr 26 x 5 Tr 28 x 5 | 1 1 1 1 | 100 100 100 100 | 0.2 / 300 0.2 / 300 0.2 / 300 0.2 / 300 | 3.30 3.05 3.33 3.92 |

| • TRC45 30 P R • TRC45 30 A R • TRC45 32 A R | • TRC45 30 P L • TRC45 30 A L • TRC45 32 A L | Tr 30 x 5 Tr 30 x 6 Tr 32 x 6 | 1 1 1 | 100 100 100 | 0.2 / 300 0.2 / 300 0.2 / 300 | 4.57 4.38 5.06 |

| • TRC45 35 P R • TRC45 35 A R • TRC45 35 M R • TRC45 36 A R | • TRC45 35 P L • TRC45 35 A L • TRC45 35 M L • TRC45 36 A L | Tr 35 x 5 Tr 35 x 6 Tr 35 x 8 Tr 36 x 6 | 1 1 1 1 | 100 100 100 100 | 0.2 / 300 0.2 / 300 0.2 / 300 0.2 / 300 | 6.40 6.16 5.85 6.56 |

| • TRC45 40 P R • TRC45 40 O R • TRC45 40 A R | • TRC45 40 P L • TRC45 40 O L • TRC45 40 A L | Tr 40 x 5 Tr 40 x 6 Tr 40 x 7 | 1 1 1 | 100 100 100 | 0.2 / 300 0.2 / 300 0.2 / 300 | 8.51 8.26 8.03 |

| • TRC45 40 M R • TRC45 40 I R • TRC45 44 A R • TRC45 45 A R | • TRC45 40 M L • TRC45 40 I L • TRC45 44 A L • TRC45 45 A L | Tr 40 x 8 Tr 40 x 10 Tr 44 x 7 Tr 45 x 8 | 1 1 1 1 | 100 100 100 100 | 0.2 / 300 0.2 / 300 0.2 / 300 0.2 / 300 | 7.90 7.49 9.90 10.23 |

| • TRC45 50 P R • TRC45 50 O R • TRC45 50 A R | • TRC45 50 P L • TRC45 50 O L • TRC45 50 A L | Tr 50 x 5 Tr 50 x 6 Tr 50 x 8 | 1 1 1 | 100 100 100 | 0.2 / 300 0.2 / 300 0.2 / 300 | 13.70 13.35 12.90 |

| • TRC45 50 I R • TRC45 55 A R | • TRC45 50 I L • TRC45 55 A L | Tr 50 x 10 Tr 55 x 9 | 1 1 | 100 100 | 0.2 / 300 0.2 / 300 | 12.37 15.51 |

| • TRC45 60 O R • TRC45 60 N R • TRC45 60 A R | • TRC45 60 O L • TRC45 60 N L • TRC45 60 A L | Tr 60 x 6 Tr 60 x 7 Tr 60 x 9 | 1 1 1 | 100 100 100 | 0.2 / 300 0.2 / 300 0.2 / 300 | 19.67 19.36 18.74 |

| • TRC45 70 A R • TRC45 80 A R • TRC45 90 A R • TRC45 95 W R | • TRC45 70 A L • TRC45 80 A L • TRC45 90 A L • TRC45 95 W L | Tr 70 x 10 Tr 80 x 10 Tr 90 x 12 Tr 95 x 16 | 1 1 1 1 | 100 100 200 200 | 0.4 / 300 0.4 / 300 0.5 / 300 1 / 300 | 25.80 34.39 43.07 45.90 |

| • TRC45 A0 A R • TRC45 A0 W R • TRC45 C0 A R • TRC45 C0 W R • TRC45 E0 A R | • TRC45 A0 A L • TRC45 A0 W L • TRC45 C0 A L • TRC45 C0 W L • TRC45 E0 A L | Tr 100 x 12 Tr 100 x 16 Tr 120 x 14 Tr 120 x 16 Tr 140 x 14 | 1 1 1 1 1 | 200 200 200 200 200 | 1 / 300 1 / 300 1 / 300 1 / 300 1 / 300 | 53.99 51.37 77.72 76.34 107.87 |

• Standard Product • Made To Order Only

| Stock no. for screw RIGHT | Stock no. for screw LEFT | Diameter x Lead | Thread Starts | Lead Accuracy μm/300mm | Straightness mm/mm | Weight kg/mt |

|---|---|---|---|---|---|---|

| • TRC45 10 J R • TRC45 12 B R | • TRC45 10 J L • TRC45 12 B L | Tr 10 x 4 (P2) Tr 12 x 6 (P3) | 2 2 | 100 100 | 0.5 / 300 0.5 / 300 | 0.48 0.65 |

| • TRC45 14 B R • TRC45 16 B R • TRC45 18 B R | • TRC45 14 B L • TRC45 16 B L • TRC45 18 B L | Tr 14 x 6 (P3) Tr 16 x 8 (P4) Tr 18 x 8 (P4) | 2 2 2 | 100 100 100 | 0.5 / 300 0.5 / 300 0.5 / 300 | 0.93 1.17 1.53 |

| • TRC45 20 B R • TRC45 20 D R | • TRC45 20 B L • TRC45 20 D L | Tr 20 x 8 (P4) Tr 20 x 20 (P5) | 2 4 | 100 100 | 0.4 / 300 0.4 / 300 | 1.94 1.84 |

| • TRC45 22 B R • TRC45 24 B R | • TRC45 22 B L • TRC45 24 B L | Tr 22 x 10 (P5) Tr 24 x 10 (P5) | 2 2 | 100 100 | 0.3 / 300 0.3 / 300 | 2.29 2.78 |

| • TRC45 25 B R • TRC45 25 E R | • TRC45 25 B L • TRC45 25 E L | Tr 25 x 10 (P5) Tr 25 x 25 (P5) | 2 5 | 100 100 | 0.3 / 300 0.3 / 300 | 3.05 3.05 |

| • TRC45 26 B R • TRC45 28 B R | • TRC45 26 B L • TRC45 28 B L | Tr 26 x 10 (P5) Tr 28 x 10 (P5) | 2 2 | 100 100 | 0.3 / 300 0.3 / 300 | 3.33 3.92 |

| • TRC45 30 B R • TRC45 30 F R | • TRC45 30 B L • TRC45 30 F L | Tr 30 x 12 (P6) Tr 30 x 30 (P5) | 2 6 | 100 100 | 0.3 / 300 0.3 / 300 | 4.38 4.57 |

| • TRC45 32 B R • TRC45 36 B R | • TRC45 32 B L • TRC45 36 B L | Tr 32 x 12 (P6) Tr 36 x 12 (P6) | 2 2 | 100 100 | 0.3 / 300 0.3 / 300 | 5.06 6.56 |

| • TRC45 40 B R • TRC45 40 E R | • TRC45 40 B L • TRC45 40 E L | Tr 40 x 14 (P7) Tr 40 x 40 (P8) | 2 5 | 100 100 | 0.3 / 300 0.3 / 300 | 8.03 7.90 |

• Standard Product • Made To Order Only

| Stock no. for screw RIGHT | Stock no. for screw LEFT | Diameter x Lead | Thread Starts | Lead Accuracy μm/300mm | Straightness mm/mm | Weight kg/mt |

|---|---|---|---|---|---|---|

| • TRC15 10 T R • TRC15 10 A R • TRC15 12 A R | • TRC15 10 T L • TRC15 10 A L • TRC15 12 A L | Tr 10 x 2 Tr 10 x 3 Tr 12 x 3 | 1 1 1 | 200 200 200 | 0.7 / 1000 0.7 / 1000 0.7 / 1000 | 0.48 0.42 0.65 |

| • TRC15 14 R R • TRC15 14 A R • TRC15 16 A R • TRC15 18 A R | • TRC15 14 R L • TRC15 14 A L • TRC15 16 A L • TRC15 18 A L | Tr 14 x 3 Tr 14 x 4 Tr 16 x 4 Tr 18 x 4 | 1 1 1 1 | 200 200 200 200 | 0.7 / 1000 0.7 / 1000 0.7 / 1500 0.7 / 1500 | 0.93 0.86 1.17 1.53 |

| • TRC15 20 A R • TRC15 22 A R • TRC15 24 A R | • TRC15 20 A L • TRC15 22 A L • TRC15 24 A L | Tr 20 x 4 Tr 22 x 5 Tr 24 x 5 | 1 1 1 | 200 200 200 | 0.6 / 2000 0.6 / 2000 0.4 / 2000 | 1.94 2.29 2.78 |

| • TRC15 25 R R • TRC15 25 A R • TRC15 26 A R • TRC15 28 A R | • TRC15 25 R L • TRC15 25 A L • TRC15 26 A L • TRC15 28 A L | Tr 25 x 3 Tr 25 x 5 Tr 26 x 5 Tr 28 x 5 | 1 1 1 1 | 200 200 200 200 | 0.4 / 2000 0.4 / 2000 0.4 / 2000 0.4 / 2000 | 3.30 3.05 3.33 3.92 |

| • TRC15 30 R R • TRC15 30 Q R • TRC15 30 P R | • TRC15 30 R L • TRC15 30 Q L • TRC15 30 P L | Tr 30 x 3 Tr 30 x 4 Tr 30 x 5 | 1 1 1 | 200 200 200 | 0.4 / 3000 0.4 / 3000 0.4 / 3000 | 4.57 4.57 4.57 |

| • TRC15 30 A R • TRC15 32 A R | • TRC15 30 A L • TRC15 32 A L | Tr 30 x 6 Tr 32 x 6 | 1 1 | 200 200 | 0.4 / 3000 0.4 / 3000 | 4.38 5.06 |

| • TRC15 35 R R • TRC15 35 Q R • TRC15 35 P R | • TRC15 35 R L • TRC15 35 Q L • TRC15 35 P L | Tr 35 x 3 Tr 35 x 4 Tr 35 x 5 | 1 1 1 | 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 6.77 6.57 6.40 |

| • TRC15 35 A R • TRC15 35 M R • TRC15 36 A R | • TRC15 35 A L • TRC15 35 M L • TRC15 36 A L | Tr 35 x 6 Tr 35 x 8 Tr 36 x 6 | 1 1 1 | 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 6.16 5.85 6.56 |

| • TRC15 40 R R • TRC15 40 Q R • TRC15 40 P R • TRC15 40 O R | • TRC15 40 R L • TRC15 40 Q L • TRC15 40 P L • TRC15 40 O L | Tr 40 x 3 Tr 40 x 4 Tr 40 x 5 Tr 40 x 6 | 1 1 1 1 | 200 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 8.95 8.71 8.51 8.26 |

| • TRC15 40 A R • TRC15 40 M R • TRC15 40 I R | • TRC15 40 A L • TRC15 40 M L • TRC15 40 I L | Tr 40 x 7 Tr 40 x 8 Tr 40 x 10 | 1 1 1 | 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 8.03 7.90 7.49 |

| • TRC15 44 A R • TRC15 45 A R | • TRC15 44 A L • TRC15 45 A L | Tr 44 x 7 Tr 45 x 8 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 9.90 10.23 |

| • TRC15 50 R R • TRC15 50 Q R • TRC15 50 P R • TRC15 50 O R | • TRC15 50 R L • TRC15 50 Q L • TRC15 50 P L • TRC15 50 O L | Tr 50 x 3 Tr 50 x 4 Tr 50 x 5 Tr 50 x 6 | 1 1 1 1 | 200 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 14.26 13.96 13.70 13.35 |

| • TRC15 50 A R • TRC15 50 I R • TRC15 55 A R | • TRC15 50 A L • TRC15 50 I L • TRC15 55 A L | Tr 50 x 8 Tr 50 x 10 Tr 55 x 9 | 1 1 1 | 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 12.90 12.37 15.51 |

| • TRC15 60 O R • TRC15 60 N R • TRC15 60 A R | • TRC15 60 O L • TRC15 60 N L • TRC15 60 A L | Tr 60 x 6 Tr 60 x 7 Tr 60 x 9 | 1 1 1 | 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 19.67 19.36 18.74 |

| • TRC15 70 A R • TRC15 80 A R | • TRC15 70 A L • TRC15 80 A L | Tr 70 x 10 Tr 80 x 10 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 25.80 34.39 |

• Standard Product • Made To Order Only

| Stock no. for screw RIGHT | Stock no. for screw LEFT | Diameter x Lead | Thread Starts | Lead Accuracy μm/300mm | Straightness mm/mm | Weight kg/mt |

|---|---|---|---|---|---|---|

| • TRC15 10 J R • TRC15 12 B R | • TRC15 10 J L • TRC15 12 B L | Tr 10 x 4 (P2) Tr 12 x 6 (P3) | 2 2 | 200 200 | 0.7 / 1000 0.7 / 1000 | 0.48 0.65 |

| • TRC15 14 B R • TRC15 16 B R • TRC15 18 B R | • TRC15 14 B L • TRC15 16 B L • TRC15 18 B L | Tr 14 x 6 (P3) Tr 16 x 8 (P4) Tr 18 x 8 (P4) | 2 2 2 | 200 200 200 | 0.7 / 1000 0.7 / 1500 0.7 / 1500 | 0.93 1.17 1.53 |

| • TRC15 20 B R • TRC15 20 D R | • TRC15 20 B L • TRC15 20 D L | Tr 20 x 8 (P4) Tr 20 x 20 (P5) | 2 4 | 200 200 | 0.6 / 2000 0.6 / 2000 | 1.94 1.84 |

| • TRC15 22 B R • TRC15 24 B R | • TRC15 22 B L • TRC15 24 B L | Tr 22 x 10 (P5) Tr 24 x 10 (P5) | 2 2 | 200 200 | 0.6 / 2000 0.4 / 2000 | 2.29 2.78 |

| • TRC15 25 B R • TRC15 25 E R | • TRC15 25 B L • TRC15 25 E L | Tr 25 x 10 (P5) Tr 25 x 25 (P5) | 2 5 | 200 200 | 0.4 / 2000 0.4 / 2000 | 3.05 3.05 |

| • TRC15 26 B R • TRC15 28 B R | • TRC15 26 B L • TRC15 28 B L | Tr 26 x 10 (P5) Tr 28 x 10 (P5) | 2 2 | 200 200 | 0.4 / 2000 0.4 / 2000 | 3.33 3.92 |

| • TRC15 30 B R • TRC15 30 F R | • TRC15 30 B L • TRC15 30 F L | Tr 30 x 12 (P6) Tr 30 x 30 (P5) | 2 6 | 200 200 | 0.4 / 3000 0.4 / 3000 | 4.38 4.57 |

| • TRC15 32 B R • TRC15 36 B R | • TRC15 32 B L • TRC15 36 B L | Tr 32 x 12 (P6) Tr 36 x 12 (P6) | 2 2 | 200 200 | 0.4 / 3000 0.3 / 3000 | 5.06 6.56 |

| • TRC15 40 B R • TRC15 40 E R | • TRC15 40 B L • TRC15 40 E L | Tr 40 x 14 (P7) Tr 40 x 40 (P8) | 2 5 | 200 200 | 0.3 / 3000 0.3 / 3000 | 8.03 7.90 |

• Standard Product • Made To Order Only

| Stock no. for screw RIGHT | Stock no. for screw LEFT | Diameter x Lead | Thread Starts | Lead Accuracy μm/300mm | Straightness mm/mm | Weight kg/mt |

|---|---|---|---|---|---|---|

| • TR304 10 T R • TR304 10 A R • TR304 12 A R | • TR304 10 T L • TR304 10 A L • TR304 12 A L | Tr 10 x 2 Tr 10 x 3 Tr 12 x 3 | 1 1 1 | 200 200 200 | 0.7 / 1000 0.7 / 1000 0.7 / 1000 | 0.48 0.42 0.65 |

| • TR304 14 R R • TR304 14 A R | • TR304 14 R L • TR304 14 A L | Tr 14 x 3 Tr 14 x 4 | 1 1 | 200 200 | 0.7 / 1000 0.7 / 1000 | 0.93 0.86 |

| • TR304 16 A R • TR304 18 A R | • TR304 16 A L • TR304 18 A L | Tr 16 x 4 Tr 18 x 4 | 1 1 | 200 200 | 0.7 / 1500 0.7 / 1500 | 1.17 1.53 |

| • TR304 20 A R • TR304 22 A R | • TR304 20 A L • TR304 22 A L | Tr 20 x 4 Tr 22 x 5 | 1 1 | 200 200 | 0.6 / 2000 0.6 / 2000 | 1.94 2.29 |

| • TR304 24 A R • TR304 25 A R | • TR304 24 A L • TR304 25 A L | Tr 24 x 5 Tr 25 x 5 | 1 1 | 200 200 | 0.4 / 2000 0.4 / 2000 | 2.78 3.05 |

| • TR304 26 A R • TR304 28 A R | • TR304 26 A L • TR304 28 A L | Tr 26 x 5 Tr 28 x 5 | 1 1 | 200 200 | 0.4 / 2000 0.4 / 2000 | 3.33 3.92 |

| • TR304 30 P R • TR304 30 A R | • TR304 30 P L • TR304 30 A L | Tr 30 x 5 Tr 30 x 6 | 1 1 | 200 200 | 0.4 / 3000 0.4 / 3000 | 4.57 4.38 |

| • TR304 32 A R • TR304 35 P R | • TR304 32 A L • TR304 35 P L | Tr 32 x 6 Tr 35 x 5 | 1 1 | 200 200 | 0.4 / 3000 0.3 / 3000 | 5.06 6.40 |

| • TR304 35 A R • TR304 36 A R | • TR304 35 A L • TR304 36 A L | Tr 35 x 6 Tr 36 x 5 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 6.16 6.56 |

| • TR304 40 P R • TR304 40 O R | • TR304 40 P L • TR304 40 O L | Tr 40 x 5 Tr 40 x 6 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 8.51 8.26 |

| • TR304 40 A R • TR304 44 A R | • TR304 40 A L • TR304 44 A L | Tr 40 x 7 Tr 44 x 7 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 8.03 9.90 |

| • TR304 50 P R • TR304 50 O R | • TR304 50 P L • TR304 50 O L | Tr 50 x 5 Tr 50 x 6 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 13.70 13.35 |

| • TR304 50 A R • TR304 55 A R | • TR304 50 A L • TR304 55 A L | Tr 50 x 8 Tr 55 x 9 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 12.90 15.51 |

| • TR304 60 O R • TR304 60 N R • TR304 60 A R | • TR304 60 O L • TR304 60 N L • TR304 60 A L | Tr 60 x 6 Tr 60 x 7 Tr 60 x 9 | 1 1 1 | 200 200 200 | 0.3 / 3000 0.3 / 3000 0.3 / 3000 | 19.67 19.36 18.74 |

| • TR304 70 A R • TR304 80 A R | • TR304 70 A L • TR304 80 A L | Tr 70 x 10 Tr 80 x 10 | 1 1 | 200 200 | 0.3 / 3000 0.3 / 3000 | 25.80 34.39 |

| • TR304 90 A R • TR304 A0 A R | • TR304 90 A L • TR304 A0 A L | Tr 90 x 12 Tr 100 x 12 | 1 1 | 200 200 | 1 / 300 1 / 300 | 43.07 53.99 |

• Standard Product • Made To Order Only

| Stock no. for screw RIGHT | Stock no. for screw LEFT | Diameter x Lead | Thread Starts | Lead Accuracy μm/300mm | Straightness mm/mm | Weight kg/mt |

|---|---|---|---|---|---|---|

| • TR304 10 J R • TR304 12 B R | • TR304 10 J L • TR304 12 B L | Tr 10 x 4 (P2) Tr 12 x 6 (P3) | 2 2 | 200 200 | 0.7 / 1000 0.7 / 1000 | 0.48 0.65 |

| • TR304 14 B R • TR304 16 B R | • TR304 14 B L • TR304 16 B L | Tr 14 x 4 (P3) Tr 16 x 8 (P4) | 2 2 | 200 200 | 0.7 / 1000 0.7 / 1500 | 0.93 1.17 |

| • TR304 18 B R • TR304 20 B R | • TR304 18 B L • TR304 20 B L | Tr 18 x 8 (P4) Tr 20 x 8 (P4) | 2 2 | 200 200 | 0.7 / 1500 0.6 / 2000 | 1.53 1.94 |

| • TR304 20 D R • TR304 22 B R | • TR304 20 D L • TR304 22 B L | Tr 20 x 20 (P5) Tr 22 x 10 (P5) | 4 2 | 200 200 | 0.4 / 2000 0.4 / 2000 | 1.84 2.29 |

| • TR304 24 B R • TR304 25 B R | • TR304 24 B L • TR304 25 B L | Tr 24 x 10 (P5) Tr 25 x 10 (P5) | 2 2 | 200 200 | 0.4 / 2000 0.4 / 2000 | 2.78 3.05 |

| • TR304 26 B R • TR304 28 B R | • TR304 26 B L • TR304 28 B L | Tr 26 x 10 (P5) Tr 28 x 10 (P5) | 2 2 | 200 200 | 0.4 / 2000 0.4 / 2000 | 3.33 3.92 |

| • TR304 30 B R • TR304 32 B R | • TR304 30 B L • TR304 32 B L | Tr 30 x 12 (P6) Tr 32 x 12 (P6) | 2 2 | 200 200 | 0.4 / 3000 0.4 / 3000 | 4.38 5.06 |

| • TR304 36 B R • TR304 40 B R | • TR304 36 B L • TR304 40 B L | Tr 36 x 12 (P6) Tr 40 x 14 (P7) | 2 2 | 200 200 | 0.3 / 3000 0.3 / 3000 | 6.56 8.03 |

• Standard Product • Made To Order Only

| Stock no. for screw RIGHT | Stock no. for screw LEFT | Diameter x Lead | Thread Starts | Lead Accuracy μm/300mm | Straightness mm/mm | Weight kg/mt |

|---|---|---|---|---|---|---|

| • TR316 10 T R • TR316 10 A R • TR316 12 A R | • TR316 10 T L • TR316 10 A L • TR316 12 A L | Tr 10 x 2 Tr 10 x 3 Tr 12 x 3 | 1 1 1 | 200 200 200 | 1.5 / 300 1.5 / 300 1.5 / 300 | 0.48 0.42 0.65 |

| • TR316 14 R R • TR316 14 A R | • TR316 14 R L • TR316 14 A L | Tr 14 x 3 Tr 14 x 4 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 0.93 0.86 |

| • TR316 16 A R • TR316 18 A R | • TR316 16 A L • TR316 18 A L | Tr 16 x 4 Tr 18 x 4 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 1.17 1.53 |

| • TR316 20 A R • TR316 22 A R | • TR316 20 A L • TR316 22 A L | Tr 20 x 4 Tr 22 x 5 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 1.94 2.29 |

| • TR316 24 A R • TR316 25 A R | • TR316 24 A L • TR316 25 A L | Tr 24 x 5 Tr 25 x 5 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 2.78 3.05 |

| • TR316 26 A R • TR316 28 A R | • TR316 26 A L • TR316 28 A L | Tr 26 x 5 Tr 28 x 5 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 3.33 3.92 |

| • TR316 30 P R • TR316 30 A R | • TR316 30 P L • TR316 30 A L | Tr 30 x 5 Tr 30 x 6 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 4.57 4.38 |

| • TR316 32 A R • TR316 35 P R | • TR316 32 A L • TR316 35 P L | Tr 32 x 6 Tr 35 x 5 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 5.06 6.40 |

| • TR316 35 A R • TR316 36 A R | • TR316 35 A L • TR316 36 A L | Tr 35 x 6 Tr 36 x 5 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 6.16 6.56 |

| • TR316 40 P R • TR316 40 O R | • TR316 40 P L • TR316 40 O L | Tr 40 x 5 Tr 40 x 6 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 8.51 8.26 |

| • TR316 40 A R • TR316 44 A R | • TR316 40 A L • TR316 44 A L | Tr 40 x 7 Tr 44 x 7 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 8.03 9.90 |

| • TR316 50 P R • TR316 50 O R | • TR316 50 P L • TR316 50 O L | Tr 50 x 5 Tr 50 x 6 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 13.70 13.35 |

| • TR316 50 A R • TR316 55 A R | • TR316 50 A L • TR316 55 A L | Tr 50 x 8 Tr 55 x 9 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 12.90 15.51 |

| • TR316 60 O R • TR316 60 N R • TR316 60 A R | • TR316 60 O L • TR316 60 N L • TR316 60 A L | Tr 60 x 6 Tr 60 x 7 Tr 60 x 9 | 1 1 1 | 200 200 200 | 1.5 / 300 1.5 / 300 1.5 / 300 | 19.67 19.36 18.74 |

| • TR316 70 A R • TR316 80 A R | • TR316 70 A L • TR316 80 A L | Tr 70 x 10 Tr 80 x 10 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 25.80 34.39 |

| • TR316 90 A R • TR316 A0 A R | • TR316 90 A L • TR316 A0 A L | Tr 90 x 12 Tr 100 x 12 | 1 1 | 200 200 | 1.5 / 300 1.5 / 300 | 43.07 53.99 |

• Standard Product • Made To Order Only

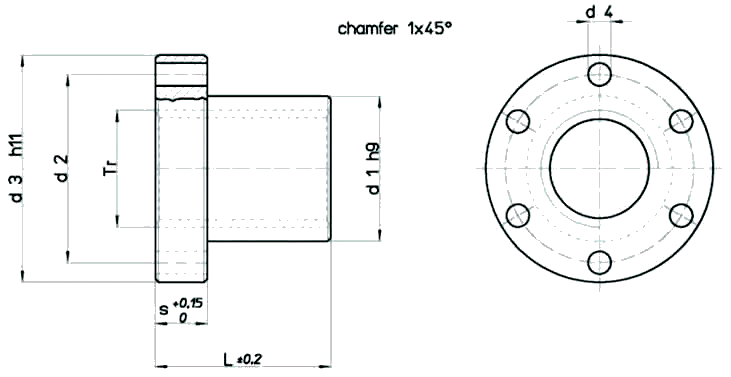

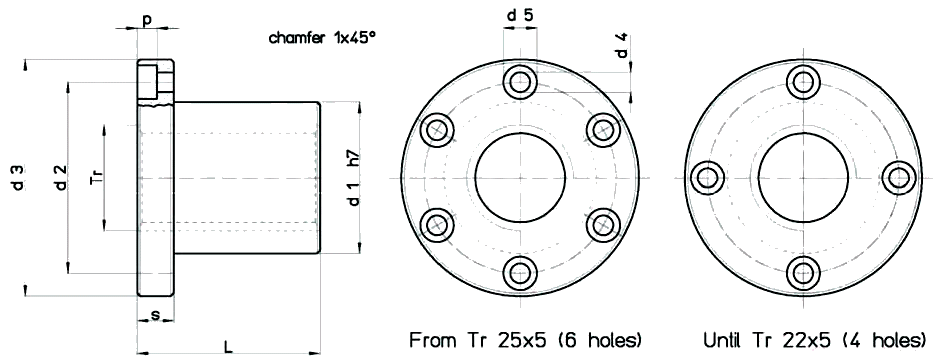

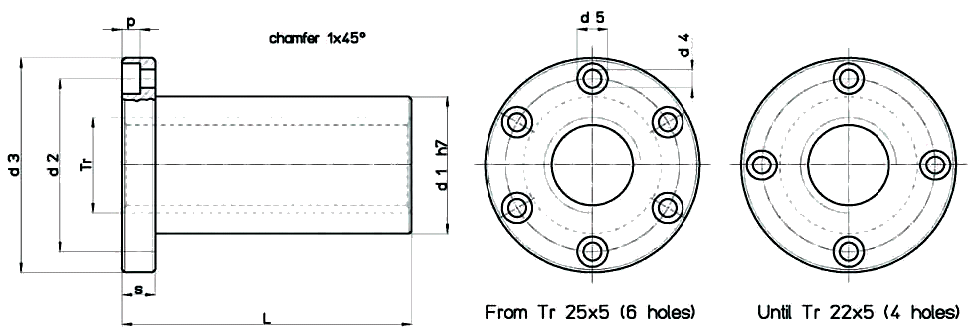

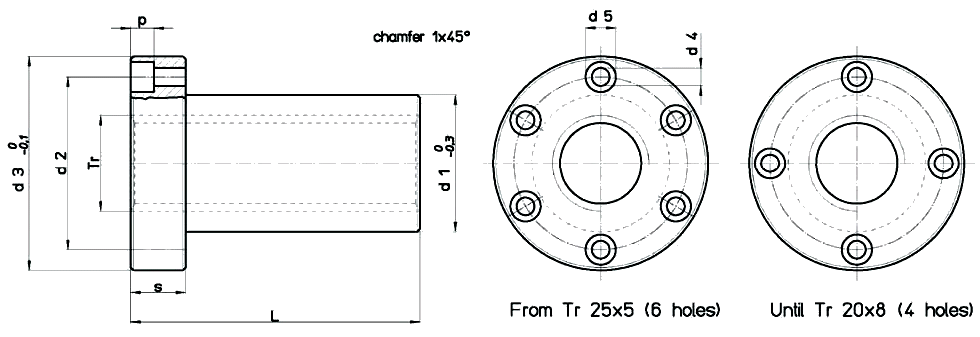

Flanged bronze nut for movement with good wear resistance. Good lubrication is recommended. Caution: These nuts have flange and fastening hole dimensions which make them NON-INTERCHANGEABLE with other flanged nuts (FBNNS, OFBN, FBNEL, FPN).

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d1 mm | d2 mm | d3 mm | d4 mm | L mm | S mm | no. screw holes | Viti di fissaggio (classe 8.8) | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FBN 10 T R | FBN 10 T L | Tr 10 x 2 | 1 | 25 | 34 | 42 | 5 | 25 | 10 | 6 | M6 | 0.164 | 250 |

| FBN 12 A R | FBN 12 A L | Tr 12 x 3 | 1 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.276 | 400 |

| FBN 12 B R | - | Tr 12 x 6 (P3) | 2 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.276 | 400 |

| FBN 14 R R | FBN 14 R L | Tr 14 x 3 | 1 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.272 | 460 |

| FBN 14 B R | - | Tr 14 x 6 (P3) | 2 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.272 | 460 |

| FBN 16 A R | FBN 16 A L | Tr 16 x 4 | 1 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.26 | 530 |

| FBN 16 B R | - | Tr 16 x 8 (P4) | 2 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.26 | 530 |

| FBN 18 A R | FBN 18 A L | Tr 18 x 4 | 1 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.247 | 610 |

| FBN 18 B R | - | Tr 18 x 8 (P4) | 2 | 28 | 38 | 48 | 6 | 35 | 12 | 6 | M6 | 0.247 | 610 |

| FBN 20 A R | FBN 20 A L | Tr 20 x 4 | 1 | 32 | 45 | 55 | 7 | 44 | 12 | 6 | M6 | 0.37 | 870 |

| FBN 20 B R | - | Tr 20 x 8 (P4) | 2 | 32 | 45 | 55 | 7 | 44 | 12 | 6 | M6 | 0.37 | 870 |

| FBN 22 A R | FBN 22 A L | Tr 22 x 5 | 1 | 32 | 45 | 55 | 7 | 44 | 12 | 6 | M6 | 0.36 | 1030 |

| FBN 22 B R | - | Tr 22 x 10 (P5) | 2 | 32 | 45 | 55 | 7 | 44 | 12 | 6 | M6 | 0.36 | 1030 |

| FBN 24 A R | FBN 24 A L | Tr 24 x 5 | 1 | 32 | 45 | 55 | 7 | 44 | 12 | 6 | M6 | 0.337 | 1040 |

| FBN 24 B R | - | Tr 24 x 10 (P5) | 2 | 32 | 45 | 55 | 7 | 44 | 12 | 6 | M6 | 0.337 | 1040 |

| FBN 26 A R | FBN 26 A L | Tr 26 x 5 | 1 | 38 | 50 | 62 | 7 | 46 | 14 | 6 | M6 | 0.516 | 1280 |

| FBN 28 A R | FBN 28 A L | Tr 28 x 5 | 1 | 38 | 50 | 62 | 7 | 46 | 14 | 6 | M6 | 0.472 | 1200 |

| FBN 28 B R | - | Tr 28 x 10 (P5) | 2 | 38 | 50 | 62 | 7 | 46 | 14 | 6 | M6 | 0.472 | 1200 |

| FBN 30 A R | FBN 30 A L | Tr 30 x 6 | 1 | 38 | 50 | 62 | 7 | 46 | 14 | 6 | M6 | 0.472 | 1370 |

| FBN 30 B R | - | Tr 30 x 12 (P6) | 2 | 32 | 50 | 62 | 7 | 46 | 14 | 6 | M6 | 0.472 | 1370 |

| FBN 32 A R | FBN 32 A L | Tr 32 x 6 | 1 | 45 | 58 | 70 | 7 | 54 | 16 | 6 | M6 | 0.779 | 1710 |

| FBN 32 B R | - | Tr 32 x 12 (P6) | 2 | 45 | 58 | 70 | 7 | 54 | 16 | 6 | M6 | 0.779 | 1710 |

| FBN 36 A R | FBN 36 A L | Tr 36 x 6 | 1 | 45 | 58 | 70 | 7 | 54 | 16 | 6 | M6 | 0.694 | 1950 |

| FBN 36 B R | - | Tr 36 x 12 (P6) | 2 | 45 | 58 | 70 | 7 | 54 | 16 | 6 | M6 | 0.694 | 1950 |

| FBN 40 A R | FBN 40 A L | Tr 40 x 7 | 1 | 63 | 78 | 95 | 9 | 66 | 16 | 6 | M6 | 1.788 | 2650 |

| FBN 40 B R | - | Tr 40 x 14 (P7) | 2 | 63 | 78 | 95 | 9 | 66 | 16 | 6 | M6 | 1.788 | 2650 |

| FBN 44 A R | FBN 44 A L | Tr 44 x 7 | 1 | 63 | 78 | 95 | 7 | 66 | 16 | 6 | M6 | 1.657 | 2940 |

| FBN 50 A R | FBN 50 A L | Tr 50 x 8 | 1 | 72 | 90 | 110 | 11 | 75 | 18 | 6 | M6 | 2.500 | 4540 |

| FBN 60 A R | FBN 60 A L | Tr 60 x 9 | 1 | 88 | 110 | 130 | 13 | 90 | 20 | 6 | M6 | 4.260 | 5490 |

| FBN 70 A R | FBN 70 A L | Tr 70 x 10 | 1 | 95 | 120 | 140 | 13 | 105 | 22 | 6 | M6 | 5.303 | 7500 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

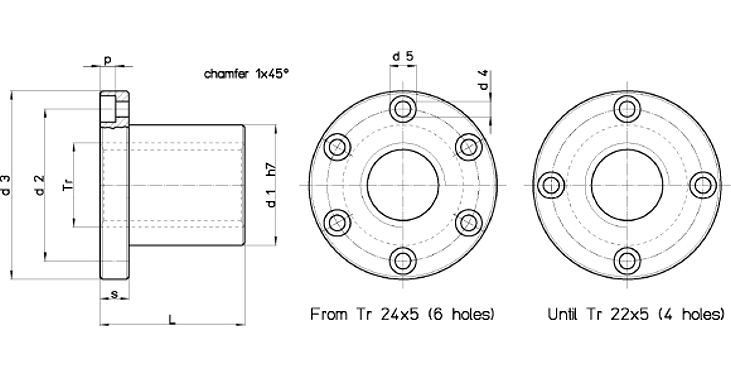

Tin bronze nut especially suitable for continuous movement with good wear resistance. Good lubrication is recommended. Flange dimensions make them fully interchangeable with FBNNS, FBNEL and FPN (total length and flange thickness change).

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d1 mm | d2 mm | d3 mm | d4 mm | d5 mm | P mm | L mm | S mm | no. screw holes | Fastening Screws (class 8.8) | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OFBN 10 A R | OFBN 10 A L | Tr 10 x 3 | 1 | 18 | 26 | 37 | 4.5 | 7.5 | 4.2 | 22 | 8 | 4 | M4 | 0.164 | 250 |

| OFBN 12 A R | OFBN 12 A L | Tr 12 x 3 | 1 | 18 | 26 | 37 | 4.5 | 7.5 | 4.2 | 22 | 8 | 4 | M4 | 0.276 | 400 |

| OFBN 12 B R | - | Tr 12 x 6 (P3) | 2 | 18 | 26 | 37 | 4.5 | 7.5 | 4.2 | 22 | 8 | 4 | M4 | 0.276 | 400 |

| OFBN 14 A R | OFBN 14 A L | Tr 14 x 4 | 1 | 20 | 30 | 42 | 5.5 | 9.5 | 5.2 | 25 | 10 | 4 | M5 | 0.272 | 460 |

| OFBN 16 A R | OFBN 16 A L | Tr 16 x 4 | 1 | 22 | 32 | 45 | 5.5 | 9.5 | 5.2 | 30 | 10 | 4 | M5 | 0.149 | 660 |

| OFBN 16 B R | - | Tr 16 x 8 (P4) | 2 | 22 | 32 | 45 | 5.5 | 9.5 | 5.2 | 30 | 10 | 4 | M5 | 0.149 | 660 |

| OFBN 18 A R | OFBN 18 A L | Tr 18 x 4 | 1 | 25 | 35 | 48 | 5.5 | 9.5 | 5.2 | 35 | 10 | 4 | M5 | 0.188 | 880 |

| OFBN 20 A R | OFBN 20 A L | Tr 20 x 4 | 1 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 40 | 10 | 4 | M5 | 0.267 | 1130 |

| OFBN 20 B R | - | Tr 20 x 8 (P4) | 2 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 40 | 10 | 4 | M5 | 0.267 | 1130 |

| OFBN 20 D R | - | Tr 20 x 20 (P5) | 4 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 40 | 10 | 4 | M5 | 0.27 | 1100 |

| OFBN 22 A R | OFBN 22 A L | Tr 22 x 5 | 1 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 45 | 10 | 4 | M5 | 0.247 | 1225 |

| OFBN 24 A R | OFBN 24 A L | Tr 24 x 5 | 1 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 45 | 12 | 6 | M6 | 0.408 | 1520 |

| OFBN 25 A R | OFBN 25 A L | Tr 25 x 5 | 1 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 45 | 12 | 6 | M6 | 0.393 | 1590 |

| OFBN 25 B R | - | Tr 25 x 10 (P5) | 2 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 45 | 12 | 6 | M6 | 0.393 | 1590 |

| OFBN 25 E R | - | Tr 25 x 25 (P5) | 5 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 45 | 12 | 4 | M6 | 0.393 | 1590 |

| OFBN 26 A R | OFBN 26 A L | Tr 26 x 5 | 1 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 45 | 12 | 6 | M6 | 0.378 | 1660 |

| OFBN 28 A R | OFBN 28 A L | Tr 28 x 5 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.532 | 2000 |

| OFBN 28 B R | - | Tr 28 x 10 (P5) | 2 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.532 | 2000 |

| OFBN 30 A R | OFBN 30 A L | Tr 30 x 6 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.497 | 2120 |

| OFBN 30 B R | - | Tr 30 x12 (P6) | 2 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.497 | 2120 |

| OFBN 30 F R | - | Tr 30 x30 (P5) | 6 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.492 | 2590 |

| OFBN 32 A R | OFBN 32 A L | Tr 32 x 6 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.455 | 2277 |

| OFBN 35 A R | OFBN 35 A L | Tr 35 x 6 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 60 | 15 | 6 | M8 | 0.883 | 3015 |

| OFBN 36 A R | OFBN 36 A L | Tr 36 x 6 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 60 | 15 | 6 | M8 | 0.854 | 3110 |

| OFBN 40 A R | OFBN 40 A L | Tr 40 x 7 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.066 | 3727 |

| OFBN 40 B R | - | Tr 40x 14 (P7) | 2 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.066 | 3727 |

| OFBN 40 E R | - | Tr 40 x 40 (P8) | 5 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.075 | 3675 |

| OFBN 44 A R | OFBN 44 A L | Tr 44 x 7 | 1 | 55 | 72 | 90 | 8.5 | 14 | 8.5 | 65 | 12 | 6 | M8 | 1.029 | 4135 |

| OFBN 45 A R | OFBN 45 A L | Tr 45 x 8 | 1 | 55 | 72 | 90 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 0.999 | 4186 |

| OFBN 50 A R | OFBN 50 A L | Tr 50 x 8 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.749 | 5780 |

| OFBN 55 A R | - | Tr 55 x 9 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.475 | 6345 |

| OFBN 60 A R | OFBN 60 A L | Tr 60 x 9 | 1 | 75 | 95 | 120 | 12.5 | 19 | 12.5 | 100 | 25 | 6 | M12 | 2.927 | 8718 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Flanged bronze nut for movement of loads. Good lubrication is recommended.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d1 mm | d2 mm | d3 mm | d4 mm | d5 mm | P mm | L mm | S mm | no. screw holes | Fastening Screws (class 8.8) | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FBNNS 10 A R | FBNNS 10 A L | Tr 10 x 3 | 1 | 18 | 26 | 37 | 4.5 | 7.5 | 4.2 | 22 | 8 | 4 | M4 | 0.088 | 294 |

| FBNNS 12 A R | FBNNS 12 A L | Tr 12 x 3 | 1 | 18 | 26 | 37 | 4.5 | 7.5 | 4.2 | 22 | 8 | 4 | M4 | 0.082 | 362 |

| FBNNS 14 A R | FBNNS 14 A L | Tr 14 x 4 | 1 | 20 | 30 | 42 | 5.5 | 9.5 | 5.2 | 25 | 10 | 4 | M5 | 0.123 | 470 |

| FBNNS 16 A R | FBNNS 16 A L | Tr 16 x 4 | 1 | 22 | 32 | 45 | 5.5 | 9.5 | 5.2 | 30 | 10 | 4 | M5 | 0.149 | 660 |

| FBNNS 18 A R | FBNNS 18 A L | Tr 18 x 4 | 1 | 25 | 35 | 48 | 5.5 | 9.5 | 5.2 | 35 | 10 | 4 | M5 | 0.188 | 880 |

| FBNNS 20 A R | FBNNS 20 A L | Tr 20 x 4 | 1 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 40 | 10 | 4 | M5 | 0.267 | 1130 |

| FBNNS 22 A R | FBNNS 22 A L | Tr 22 x 5 | 1 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 40 | 10 | 4 | M5 | 0.247 | 1225 |

| FBNNS 25 A R | FBNNS 25 A L | Tr 25 x 5 | 1 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 45 | 12 | 6 | M6 | 0.393 | 1590 |

| FBNNS 28 A R | FBNNS 28 A L | Tr 28 x 5 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.532 | 2000 |

| FBNNS 30 R R | FBNNS 30 R L | Tr 30 x 3 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.482 | 2238 |

| FBNNS 30 Q R | FBNNS 30 Q L | Tr 30 x 4 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.487 | 2200 |

| FBNNS 30 P R | FBNNS 30 P L | Tr 30 x 5 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M5 | 0.492 | 2160 |

| FBNNS 30 A R | FBNNS 30 A L | Tr 30 x 6 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 50 | 12 | 6 | M6 | 0.497 | 2120 |

| FBNNS 35 R R | FBNNS 35 R L | Tr 35 x 3 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 60 | 15 | 6 | M8 | 0.862 | 3160 |

| FBNNS 35 Q R | FBNNS 35 Q L | Tr 35 x 4 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 60 | 15 | 6 | M8 | 0.869 | 3110 |

| FBNNS 35 P R | FBNNS 35 P L | Tr 35 x 5 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 60 | 15 | 6 | M8 | 0.876 | 3060 |

| FBNNS 35 A R | FBNNS 35 A L | Tr 35 x 6 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 60 | 15 | 6 | M8 | 0.883 | 3015 |

| FBNNS 35 M R | - | Tr 35 x 8 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 60 | 15 | 6 | M8 | 0.898 | 2920 |

| FBNNS 40 R R | FBNNS 40 R L | Tr 40 x 3 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.03 | 3930 |

| FBNNS 40 Q R | FBNNS 40 Q L | Tr 40 x 4 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.039 | 3880 |

| FBNNS 40 P R | FBNNS 40 P L | Tr 40 x 5 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.048 | 3828 |

| FBNNS 40 O R | FBNNS 40 O L | Tr 40 x 6 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.057 | 3778 |

| FBNNS 40 A R | FBNNS 40 A L | Tr 40 x 7 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.066 | 3727 |

| FBNNS 40 M R | - | Tr 40 x 8 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 1.075 | 3675 |

| FBNNS 45 A R | FBNNS 45 A L | Tr 45 x 8 | 1 | 55 | 72 | 90 | 8.5 | 14 | 8.5 | 65 | 15 | 6 | M8 | 0.999 | 4186 |

| FBNNS 50 R R | FBNNS 50 R L | Tr 50 x 3 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.679 | 6095 |

| FBNNS 50 Q R | FBNNS 50 Q L | Tr 50 x 4 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.693 | 6030 |

| FBNNS 50 P R | FBNNS 50 P L | Tr 50 x 5 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.707 | 5970 |

| FBNNS 50 O R | FBNNS 50 O L | Tr 50 x 6 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.721 | 5905 |

| FBNNS 50 A R | FBNNS 50 A L | Tr 50 x 8 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.749 | 5780 |

| FBNNS 55 A R | - | Tr 55 x 9 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 80 | 20 | 6 | M10 | 1.475 | 6345 |

| FBNNS 60 O R | FBNNS 60 O L | Tr 60 x 6 | 1 | 75 | 95 | 120 | 12.5 | 19 | 12.5 | 100 | 25 | 6 | M12 | 2.865 | 8950 |

| FBNNS 60 N R | FBNNS 60 N L | Tr 60 x 7 | 1 | 75 | 95 | 120 | 12.5 | 19 | 12.5 | 100 | 25 | 6 | M12 | 2.886 | 8875 |

| FBNNS 60 A R | FBNNS 60 A L | Tr 60 x 9 | 1 | 75 | 95 | 120 | 12.5 | 19 | 12.5 | 100 | 25 | 6 | M12 | 2.927 | 8718 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Flanged Bronze Nut of considerable length 3xTr suitable for operation under load with high loads and/or high movement speed. The special length of 3xTr greatly limits wear. Good lubrication is recommended.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d1 mm | d2 mm | d3 mm | d4 mm | d5 mm | P mm | L mm | S mm | no. screw holes | Fastening Screws (class 8.8) | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FBNEL 14 A R | FBNEL 14 A L | Tr 14 x 4 | 1 | 20 | 30 | 42 | 5.5 | 9.5 | 5.2 | 42 | 10 | 4 | M5 | 0.151 | 790 |

| FBNEL 16 A R | FBNEL 16 A L | Tr 16 x 4 | 1 | 22 | 32 | 45 | 5.5 | 9.5 | 5.2 | 48 | 10 | 4 | M5 | 0.183 | 1056 |

| FBNEL 16 B R | - | Tr 16 x 8 (P4) | 2 | 22 | 32 | 45 | 5.5 | 9.5 | 5.2 | 48 | 10 | 4 | M5 | 0.183 | 1056 |

| FBNEL 18 A R | FBNEL 18 A L | Tr 18 x 4 | 1 | 25 | 35 | 48 | 5.5 | 9.5 | 5.2 | 54 | 10 | 4 | M5 | 0.233 | 1356 |

| FBNEL 20 A R | FBNEL 20 A L | Tr 20 x 4 | 1 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 60 | 12 | 4 | M5 | 0.368 | 1696 |

| FBNEL 20 B R | - | Tr 20 x 8 (P4) | 2 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 60 | 12 | 4 | M5 | 0.368 | 1696 |

| FBNEL 22 A R | FBNEL 22 A L | Tr 22 x 5 | 1 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 60 | 12 | 4 | M5 | 0.338 | 1838 |

| FBNEL 25 A R | FBNEL 25 A L | Tr 25 x 5 | 1 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 75 | 15 | 6 | M6 | 0.586 | 2650 |

| FBNEL 25 B R | - | Tr 25 x 10 (P5) | 2 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 75 | 15 | 6 | M6 | 0.586 | 2650 |

| FBNEL 25 E R | - | Tr 25 x 25 (P5) | 5 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 75 | 15 | 6 | M6 | 0.586 | 2650 |

| FBNEL 28 A R | FBNEL 28 A L | Tr 28 x 5 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 18 | 6 | M6 | 0.903 | 3600 |

| FBNEL 28 B R | - | Tr 28 x 10 (P5) | 2 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 18 | 6 | M6 | 0.903 | 3600 |

| FBNEL 30 A R | FBNEL 30 A L | Tr 30 x 6 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 18 | 6 | M6 | 0.841 | 3816 |

| FBNEL 30 B R | - | Tr 30 x 12 (P6) | 2 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 18 | 6 | M6 | 0.841 | 3816 |

| FBNEL 30 R R | FBNEL 30 R L | Tr 30 x 3 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 18 | 6 | M6 | 0.784 | 3816 |

| FBNEL 32 A R | FBNEL 32 A L | Tr 32 x 6 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 18 | 6 | M6 | 0.765 | 4100 |

| FBNEL 35 A R | FBNEL 35 A L | Tr 35 x 6 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 105 | 20 | 6 | M8 | 1.439 | 5277 |

| FBNEL 40 A R | FBNEL 40 A L | Tr 40 x 7 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 120 | 25 | 6 | M8 | 1.937 | 6880 |

| FBNEL 40 I R | - | Tr 40 x 10 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 120 | 25 | 6 | M8 | 1.986 | 6597 |

| FBNEL 40 B R | - | Tr 40 x 14 (P7) | 2 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 120 | 25 | 6 | M8 | 1.937 | 6597 |

| FBNEL 40 Q R | - | Tr 40 x 4 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 120 | 25 | 6 | M8 | 1.929 | 6597 |

| FBNEL 50 O R | - | Tr 50 x 6 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 150 | 30 | 6 | M10 | 3.007 | 10840 |

| FBNEL 50 A R | FBNEL 50 A L | Tr 50 x 8 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 150 | 30 | 6 | M10 | 3.075 | 10840 |

| FBNEL 50 I R | - | Tr 50 x 10 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 150 | 30 | 6 | M10 | 3.127 | 10600 |

| FBNEL 60 A R | FBNEL 60 A L | Tr 60 x 9 | 1 | 75 | 95 | 120 | 12.5 | 19 | 12.5 | 180 | 35 | 6 | M12 | 4.797 | 15700 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

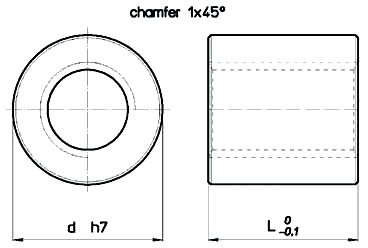

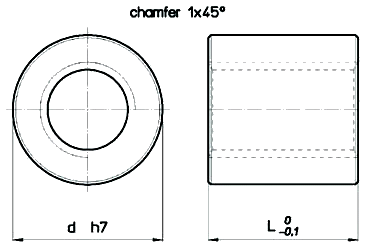

Cylindrical Bronze Nut for movement with modest loads compared with OFBN and FBNEL.

Good lubrication is recommended.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d mm | L mm | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|

| RBND 12 A R | RBND 12 A L | Tr 12 x 3 | 1 | 36 | 36 | 0.302 | 594 |

| RBND 14 A R | RBND 14 A L | Tr 14 x 4 | 1 | 36 | 36 | 0.29 | 677 |

| RBND 16 A R | RBND 16 A L | Tr 16 x 4 | 1 | 36 | 36 | 0.276 | 792 |

| RBND 16 B R | - | Tr 16 x 8 (P4) | 2 | 36 | 36 | 0.276 | 792 |

| RBND 18 A R | RBND 18 A L | Tr 18 x 4 | 1 | 36 | 36 | 0.259 | 905 |

| RBND 20 A R | RBND 20 A L | Tr 20 x 4 | 1 | 40 | 40 | 0.354 | 1130 |

| RBND 20 B R | - | Tr 20 x 8 (P4) | 2 | 40 | 40 | 0.354 | 1130 |

| RBND 22 A R | RBND 22 A L | Tr 22 x 5 | 1 | 40 | 40 | 0.33 | 1225 |

| RBND 25 A R | RBND 25 A L | Tr 25 x 5 | 1 | 45 | 45 | 0.47 | 1590 |

| RBND 25 B R | - | Tr 25 x 10 (P5) | 2 | 45 | 45 | 0.47 | 1590 |

| RBND 28 A R | RBND 28 A L | Tr 28 x 5 | 1 | 45 | 45 | 0.42 | 1800 |

| RBND 28 B R | - | Tr 28 x 10 (P5) | 2 | 45 | 45 | 0.42 | 1800 |

| RBND 30 A R | RBND 30 A L | Tr 30 x 6 | 1 | 50 | 50 | 0.6 | 2120 |

| RBND 30 B R | - | Tr 30 x 12 (P6) | 2 | 50 | 50 | 0.6 | 2120 |

| RBND 35 A R | RBND 35 A L | Tr 35 x 6 | 1 | 55 | 55 | 0.75 | 2764 |

| RBND 40 A R | RBND 40 A L | Tr 40 x 7 | 1 | 60 | 60 | 0.92 | 3440 |

| RBND 40 B R | - | Tr 40 x 14 (P7) | 2 | 60 | 60 | 0.92 | 3440 |

| RBND 45 A R | RBND 45 A L | Tr 45 x 8 | 1 | 65 | 65 | 1.1 | 4186 |

| RBND 50 A R | RBND 50 A L | Tr 50 x 8 | 1 | 70 | 70 | 1.3 | 5057 |

| RBND 55 A R | - | Tr 55 x 9 | 1 | 80 | 80 | 2.07 | 6345 |

| RBND 60 A R | RBND 60 A L | Tr 60 x 9 | 1 | 80 | 80 | 1.75 | 6975 |

Cylindrical Bronze Nut for movement with modest loads compared with OFBN and FBNEL.

Good lubrication is recommended.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d mm | L mm | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|

| RBN 10 A R | RBN 10 A L | Tr 10 x 3 | 1 | 22 | 20 | 0.057 | 320 |

| RBN 12 A R | RBN 12 A L | Tr 12 x 3 | 1 | 26 | 24 | 0.094 | 396 |

| RBN 12 B R | - | Tr 12 x 6 (P3) | 2 | 26 | 24 | 0.094 | 396 |

| RBN 14 A R | RBN 14 A L | Tr 14 x 4 | 1 | 30 | 28 | 0.146 | 526 |

| RBN 16 A R | RBN 16 A L | Tr 16 x 4 | 1 | 36 | 32 | 0.245 | 704 |

| RBN 18 A R | RBN 18 A L | Tr 18 x 4 | 1 | 40 | 36 | 0.337 | 905 |

| RBN 20 A R | RBN 20 A L | Tr 20 x 4 | 1 | 45 | 40 | 0.476 | 1130 |

| RBN 22 A R | RBN 22 A L | Tr 22 x 5 | 1 | 45 | 40 | 0.456 | 1225 |

| RBN 24 A R | RBN 24 A L | Tr 24 x 5 | 1 | 50 | 48 | 0.68 | 1620 |

| RBN 26 A R | RBN 26 A L | Tr 26 x 5 | 1 | 50 | 48 | 0.648 | 1770 |

| RBN 28 A R | RBN 28 A L | Tr 28 x 5 | 1 | 60 | 60 | 1.237 | 2400 |

| RBN 30 A R | RBN 30 A L | Tr 30 x 6 | 1 | 60 | 60 | 1.195 | 2544 |

| RBN 32 A R | RBN 32 A L | Tr 32 x 6 | 1 | 60 | 60 | 1.145 | 2733 |

| RBN 36 A R | RBN 36 A L | Tr 36 x 6 | 1 | 75 | 72 | 2.232 | 3732 |

| RBN 40 A R | RBN 40 A L | Tr 40 x 7 | 1 | 80 | 80 | 2.823 | 4587 |

| RBN 44 A R | RBN 44 A L | Tr 44 x 7 | 1 | 80 | 80 | 2.639 | 5090 |

| RBN 50 A R | RBN 50 A L | Tr 50 x 8 | 1 | 90 | 100 | 4.142 | 7224 |

| RBN 60 A R | RBN 60 A L | Tr 60 x 9 | 1 | 100 | 120 | 5.716 | 10462 |

| RBN 70 A R | RBN 70 A L | Tr 70 x 10 | 1 | 110 | 140 | 7.548 | 10200 |

| RBN 80 A R | RBN 80 A L | Tr 80 x 10 | 1 | 120 | 160 | 9.6 | 18850 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Large Cylindrical Nut with non-standard pitches.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d mm | L mm | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|

| LRBN 20 A R | LRBN 20 A L | Tr 20 x 4 | 1 | 78 | 60 | 2.43 | 1696 |

| LRBN 25 A R | LRBN 25 A L | Tr 25 x 5 | 1 | 78 | 75 | 2.96 | 2650 |

| LRBN 30 R R | LRBN 30 R L | Tr 30 x 3 | 1 | 78 | 90 | 3.3 | 3600 |

| LRBN 30 Q R | LRBN 30 Q L | Tr 30 x 4 | 1 | 78 | 90 | 3.31 | 3560 |

| LRBN 30 P R | LRBN 30 P L | Tr 30 x 5 | 1 | 78 | 90 | 3.32 | 3500 |

| LRBN 30 A R | LRBN 30 A L | Tr 30 x 6 | 1 | 78 | 90 | 3.33 | 3435 |

| LRBN 35 R R | LRBN 35 R L | Tr 35 x 3 | 1 | 88 | 105 | 4.85 | 5000 |

| LRBN 35 Q R | LRBN 35 Q L | Tr 35 x 4 | 1 | 88 | 105 | 4.86 | 4900 |

| LRBN 35 P R | LRBN 35 P L | Tr 35 x 5 | 1 | 88 | 105 | 4.87 | 4820 |

| LRBN 35 A R | LRBN 35 A L | Tr 35 x 6 | 1 | 88 | 105 | 4.89 | 4750 |

| LRBN 40 R R | LRBN 40 R L | Tr 40 x 3 | 1 | 98 | 120 | 6.8 | 6530 |

| LRBN 40 Q R | LRBN 40 Q L | Tr 40 x 4 | 1 | 98 | 120 | 6.82 | 6447 |

| LRBN 40 P R | LRBN 40 P L | Tr 40 x 5 | 1 | 98 | 120 | 6.83 | 6360 |

| LRBN 40 O R | LRBN 40 O L | Tr 40 x 6 | 1 | 98 | 120 | 6.85 | 6277 |

| LRBN 40 A R | LRBN 40 A L | Tr 40 x 7 | 1 | 98 | 120 | 6.87 | 6200 |

| LRBN 40 I R | - | Tr 40 x 10 | 1 | 98 | 120 | 6.91 | 6597 |

| LRBN 50 R R | LRBN 50 R L | Tr 50 x 3 | 1 | 108 | 150 | 9.74 | 10300 |

| LRBN 50 Q R | LRBN 50 Q L | Tr 50 x 4 | 1 | 108 | 150 | 9.77 | 10180 |

| LRBN 50 P R | LRBN 50 P L | Tr 50 x 5 | 1 | 108 | 150 | 9.79 | 10070 |

| LRBN 50 O R | LRBN 50 O L | Tr 50 x 6 | 1 | 108 | 150 | 9.82 | 9965 |

| LRBN 50 A R | LRBN 50 A L | Tr 50 x 8 | 1 | 108 | 150 | 9.87 | 9750 |

| LRBN 50 I R | - | Tr 50 x 10 | 1 | 108 | 150 | 9.92 | 10600 |

| LRBN 60 O R | - | Tr 60 x 6 | 1 | 118 | 180 | 13.29 | 14500 |

| LRBN 60 N R | - | Tr 60 x 7 | 1 | 118 | 180 | 13.32 | 14380 |

| LRBN 60 A R | - | Tr 60 x 9 | 1 | 118 | 180 | 13.36 | 14130 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Nut for fastening or manual movement with small load; steel-to-steel coupling tends to seize.

Can be MIG welded only. Electrode welding is not recommended because of the lead.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d mm | L mm | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|

| RSND 12 A R | RSND 12 A L | Tr 12 x 3 | 1 | 36 | 36 | 0.255 | 592 |

| RSND 14 A R | RSND 14 A L | Tr 14 x 4 | 1 | 36 | 36 | 0.25 | 677 |

| RSND 16 A R | RSND 16 A L | Tr 16 x 4 | 1 | 36 | 36 | 0.238 | 792 |

| RSND 16 B R | - | Tr 16 x 8 (P4) | 2 | 36 | 36 | 0.238 | 792 |

| RSND 18 A R | RSND 18 A L | Tr 18 x 4 | 1 | 36 | 36 | 0.224 | 905 |

| RSND 20 A R | RSND 20 A L | Tr 20 x 4 | 1 | 40 | 40 | 0.306 | 1130 |

| RSND 20 B R | - | Tr 20 x 8 (P4) | 2 | 40 | 40 | 0.306 | 1130 |

| RSND 22 A R | RSND 22 A L | Tr 22 x 5 | 1 | 40 | 40 | 0.29 | 1225 |

| RSND 25 A R | RSND 25 A L | Tr 25 x 5 | 1 | 45 | 45 | 0.4 | 1590 |

| RSND 25 B R | - | Tr 25 x 10 (P5) | 2 | 45 | 45 | 0.4 | 1590 |

| RSND 28 A R | RSND 28 A L | Tr 28 x 5 | 1 | 45 | 45 | 0.36 | 1800 |

| RSND 28 B R | - | Tr 28 x 10 (P5) | 2 | 45 | 45 | 0.36 | 1800 |

| RSND 30 A R | RSND 30 A L | Tr 30 x 6 | 1 | 50 | 50 | 0.52 | 2120 |

| RSND 30 B R | - | Tr 30 x 12 (P6) | 2 | 50 | 50 | 0.52 | 2120 |

| RSND 35 A R | RSND 35 A L | Tr 35 x 6 | 1 | 55 | 55 | 0.65 | 2764 |

| RSND 40 A R | RSND 40 A L | Tr 40 x 7 | 1 | 60 | 60 | 0.79 | 3440 |

| RSND 40 B R | - | Tr 40 x 14 (P7) | 2 | 60 | 60 | 0.79 | 3440 |

| RSND 45 A R | RSND 45 A L | Tr 45 x 8 | 1 | 65 | 65 | 0.95 | 4186 |

| RSND 50 A R | RSND 50 A L | Tr 50 x 8 | 1 | 70 | 70 | 1.12 | 5057 |

| RSND 55 A R | - | Tr 55 x 9 | 1 | 80 | 80 | 1.78 | 6345 |

| RSND 60 A R | RSND 60 A L | Tr 60 x 9 | 1 | 80 | 80 | 1.51 | 6975 |

Used as fastening nut for manual movement where load is negligible because steel-to-steel coupling used for moving under loads tends to seize. Material is weldable.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d mm | L mm | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|

| RSN 10 A R | RSN 10 A L | Tr 10 x 3 | 1 | 22 | 15 | 0.037 | 240 |

| RSN 12 A R | RSN 12 A L | Tr 12 x 3 | 1 | 26 | 18 | 0.061 | 296 |

| RSN 12 B R | - | Tr 12 x 6 (P3) | 2 | 26 | 18 | 0.061 | 296 |

| RSN 14 A R | RSN 14 A L | Tr 14 x 4 | 1 | 30 | 21 | 0.095 | 395 |

| RSN 16 A R | RSN 16 A L | Tr 16 x 4 | 1 | 36 | 24 | 0.158 | 528 |

| RSN 18 A R | RSN 18 A L | Tr 18 x 4 | 1 | 40 | 27 | 0.218 | 553 |

| RSN 20 A R | RSN 20 A L | Tr 20 x 4 | 1 | 45 | 30 | 0.308 | 847 |

| RSN 22 A R | RSN 22 A L | Tr 22 x 5 | 1 | 45 | 33 | 0.324 | 1010 |

| RSN 24 A R | RSN 24 A L | Tr 24 x 5 | 1 | 50 | 36 | 0.44 | 1215 |

| RSN 26 A R | RSN 26 A L | Tr 26 x 5 | 1 | 50 | 39 | 0.454 | 1440 |

| RSN 28 A R | RSN 28 A L | Tr 28 x 5 | 1 | 60 | 42 | 0.747 | 1680 |

| RSN 30 A R | RSN 30 A L | Tr 30 x 6 | 1 | 60 | 45 | 0.773 | 1908 |

| RSN 32 A R | RSN 32 A L | Tr 32 x 6 | 1 | 60 | 48 | 0.79 | 2186 |

| RSN 36 A R | RSN 36 A L | Tr 36 x 6 | 1 | 75 | 54 | 1.476 | 2800 |

| RSN 40 A R | RSN 40 A L | Tr 40 x 7 | 1 | 80 | 60 | 1.826 | 3440 |

| RSN 44 A R | RSN 44 A L | Tr 44 x 7 | 1 | 80 | 66 | 1.878 | 4200 |

| RSN 50 A R | RSN 50 A L | Tr 50 x 8 | 1 | 90 | 75 | 2.68 | 5418 |

| RSN 60 A R | RSN 60 A L | Tr 60 x 9 | 1 | 100 | 90 | 3.698 | 7847 |

| RSN 70 A R | RSN 70 A L | Tr 70 x 10 | 1 | 110 | 105 | 4.884 | 10200 |

| RSN 80 A R | RSN 80 A L | Tr 80 x 10 | 1 | 120 | 120 | 6.21 | 14137 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Fixing nut very convenient thanks to its hexagonal shape. Not suitable for operations with high loads, because the coupling steel-to-steel tends to seize. This nut can be MIG welded only. Electrode welding is not recommended because of the lead.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d mm | L mm | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|

| HSN 10 T R | HSN 10 T L | Tr 10 x 2 | 1 | 17 | 15 | 0.023 | 150 |

| HSN 10 A R | HSN 10 A L | Tr 10 x 3 | 1 | 17 | 15 | 0.021 | 240 |

| HSN 12 A R | HSN 12 A L | Tr 12 x 3 | 1 | 19 | 18 | 0.027 | 296 |

| HSN 14 R R | HSN 14 R L | Tr 14 x 3 | 1 | 22 | 21 | 0.044 | 395 |

| HSN 14 A R | HSN 14 A L | Tr 14 x 4 | 1 | 22 | 21 | 0.044 | 395 |

| HSN 16 A R | HSN 16 A L | Tr 16 x 4 | 1 | 27 | 24 | 0.082 | 528 |

| HSN 18 A R | HSN 18 A L | Tr 18 x 4 | 1 | 27 | 27 | 0.084 | 553 |

| HSN 20 A R | HSN 20 A L | Tr 20 x 4 | 1 | 30 | 30 | 0.114 | 847 |

| HSN 22 A R | HSN 22 A L | Tr 22 x 5 | 1 | 30 | 33 | 0.112 | 1010 |

| HSN 24 A R | HSN 24 A L | Tr 24 x 5 | 1 | 36 | 36 | 0.2 | 1215 |

| HSN 26 A R | HSN 26 A L | Tr 26 x 5 | 1 | 36 | 39 | 0.193 | 1440 |

| HSN 28 A R | HSN 28 A L | Tr 28 x 5 | 1 | 41 | 42 | 0.291 | 1680 |

| HSN 30 A R | HSN 30 A L | Tr 30 x 6 | 1 | 46 | 45 | 0.42 | 1908 |

| HSN 32 A R | HSN 32 A L | Tr 32 x 6 | 1 | 46 | 48 | 0.411 | 2186 |

| HSN 36 A R | HSN 36 A L | Tr 36 x 6 | 1 | 55 | 54 | 0.706 | 2800 |

| HSN 40 A R | HSN 40 A L | Tr 40 x 7 | 1 | 65 | 60 | 1.172 | 3440 |

| HSN 44 A R | HSN 44 A L | Tr 44 x 7 | 1 | 65 | 66 | 1.159 | 4200 |

| HSN 50 A R | HSN 50 A L | Tr 50 x 8 | 1 | 75 | 75 | 1.783 | 5418 |

| HSN 60 A R | HSN 60 A L | Tr 60 x 9 | 1 | 90 | 90 | 3.087 | 7847 |

| HSN 70 A R | HSN 70 A L | Tr 70 x 10 | 1 | 90 | 105 | 2.837 | 10200 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Highly wear resistant cylindrical plastic nut. Designed for low to medium loads. Lubricate RPN nuts occasionally with grease or oil to improve life. Do not use molybdenum disulfide MoS2 lubricants or graphite.

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d mm | L mm | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|

| RPN 12 A R | RPN 12 A L | Tr 12 x 3 | 1 | 26 | 24 | 0.012 | 396 |

| RPN 16 A R | RPN 16 A L | Tr 16 x 4 | 1 | 36 | 32 | 0.03 | 704 |

| RPN 20 A R | RPN 20 A L | Tr 20 x 4 | 1 | 45 | 40 | 0.06 | 1130 |

| RPN 25 A R | RPN 25 A L | Tr 25 x 5 | 1 | 50 | 48 | 0.083 | 1696 |

| RPN 28 A R | RPN 28 A L | Tr 28 x 5 | 1 | 60 | 60 | 0.154 | 2400 |

| RPN 28 B R | - | Tr 28 x 10 (P5) | 2 | 60 | 60 | 0.154 | 2400 |

| RPN 30 A R | RPN 30 A L | Tr 30 x 6 | 1 | 60 | 60 | 0.15 | 2544 |

| RPN 35 A R | RPN 35 A L | Tr 35 x 6 | 1 | 75 | 72 | 0.29 | 3618 |

| RPN 40 A R | RPN 40 A L | Tr 40 x 7 | 1 | 80 | 80 | 0.355 | 4587 |

| RPN 50 A R | RPN 50 A L | Tr 50 x 8 | 1 | 90 | 100 | 0.523 | 7225 |

Important Note:

RPN plastic nuts are recommended to be used with stainless steel screws only.

This type of nut is made of a very wear-resistant perfectly self-lubricating plastic. It doesn’t require any other lubrication as long as it is in use. The 3 x d length gives better load distribution and limits wear. The flange dimensions make them fully interchangeable with the FBNNS, OFBN and FBNEL (total length and flange thickness are variable).

| Nut Stock no. RIGHT | Nut Stock no. LEFT | Diameter x Lead | Thread Starts | d1 mm | d2 mm | d3 mm | d4 mm | d5 mm | P mm | L mm | S mm | no. screw holes | Fastening Screws (class 8.8) | Wt. kg/each | At mm2 (1) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FPN 12 A R | FPN 12 A L | Tr 12 x 3 | 1 | 18 | 26 | 37 | 4.5 | 7.5 | 4.2 | 36 | 12 | 4 | M4 | 0.016 | 594 |

| FPN 16 A R | FPN 16 A L | Tr 16 x 4 | 1 | 22 | 32 | 45 | 5.5 | 9.5 | 5.2 | 48 | 16 | 4 | M5 | 0.03 | 1056 |

| FPN 20 A R | FPN 20 A L | Tr 20 x 4 | 1 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 60 | 20 | 4 | M5 | 0.057 | 1696 |

| FPN 20 B R | - | Tr 20 x 8 (P4) | 2 | 30 | 40 | 52 | 5.5 | 9.5 | 5.2 | 60 | 20 | 4 | M5 | 0.057 | 1696 |

| FPN 25 A R | FPN 25 A L | Tr 25 x 5 | 1 | 35 | 48 | 62 | 6.5 | 11 | 6.5 | 75 | 25 | 6 | M6 | 0.094 | 2650 |

| FPN 28 A R | FPN 28 A L | Tr 28 x 5 | 1 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 30 | 6 | M6 | 0.142 | 3600 |

| FPN 28 B R | - | Tr 28 x 10 (P5) | 2 | 40 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 30 | 6 | M6 | 0.142 | 3600 |

| FPN 30 A R | FPN 30 A L | Tr 30 x 6 | 1 | 45 | 53 | 68 | 6.5 | 11 | 6.5 | 90 | 30 | 6 | M6 | 0.135 | 3816 |

| FPN 35 A R | FPN 35 A L | Tr 35 x 6 | 1 | 50 | 63 | 78 | 8.5 | 14 | 8.5 | 105 | 35 | 6 | M8 | 0.221 | 5277 |

| FPN 40 A R | FPN 40 A L | Tr 40 x 7 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 120 | 40 | 6 | M8 | 0.289 | 6880 |

| FPN 40 I R | - | Tr 40 x 10 | 1 | 55 | 68 | 84 | 8.5 | 14 | 8.5 | 120 | 40 | 6 | M8 | 0.252 | 6597 |

| FPN 50 A R | FPN 50 A L | Tr 50 x 8 | 1 | 65 | 80 | 100 | 10.5 | 17 | 10.5 | 150 | 50 | 6 | M10 | 0.476 | 10840 |

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

| Diameter x Lead | d1 Major diameter tollerance 4h mm | d2 Effective or pitch dia. tollerance 7e mm | d3 Minor diameter tollerance 7h mm | Thread Starts | Lead Angle | (1) Efficiency ŋ | (2) H1 mm | I Moment of inertia mm4 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | f=0.1 | f=0.2 | |||||

| Tr 10 x 2 | 9.820 | 10.000 | 8.739 | 8.929 | 7.191 | 7.500 | 1 | 4°02´ | 0.41 | 0.26 | 1 | 131 |

| Tr 10 x 3 | 9.764 | 10.000 | 8.203 | 8.415 | 6.150 | 6.500 | 1 | 6°25´ | 0.52 | 0.35 | 1.5 | 70 |

| Tr 10 x 4 (P2) | 9.820 | 10.000 | 8.739 | 8.929 | 7.191 | 7.500 | 2 | 8°03´ | 0.58 | 0.40 | 1 | 131 |

| Tr 12 x 3 | 11.764 | 12.000 | 10.191 | 10.415 | 8.135 | 8.500 | 1 | 5°12´ | 0.47 | 0.31 | 1.5 | 215 |

| Tr 12 x 6 (P3) | 11.764 | 12.000 | 10.191 | 10.415 | 8.135 | 8.500 | 2 | 10°19´ | 0.63 | 0.46 | 1.5 | 215 |

| Tr 14 x 3 | 13.764 | 14.000 | 12.191 | 12.415 | 10.135 | 10.500 | 1 | 4°22´ | 0.43 | 0.27 | 1.5 | 518 |

| Tr 14 x 4 | 13.700 | 14.000 | 11.640 | 11.905 | 9.074 | 9.500 | 1 | 6°03´ | 0.51 | 0.34 | 2 | 333 |

| Tr 14 x 6 (P3) | 13.764 | 14.000 | 12.191 | 12.415 | 10.135 | 10.500 | 2 | 8°41´ | 0.59 | 0.42 | 1.5 | 518 |

| Tr 16 x 4 | 15.700 | 16.000 | 13.640 | 13.905 | 11.074 | 11.500 | 1 | 5°12´ | 0.47 | 0.31 | 2 | 738 |

| Tr 16 x 8 (P4) | 15.700 | 16.000 | 13.640 | 13.905 | 11.074 | 11.500 | 2 | 10°19´ | 0.63 | 0.46 | 2 | 738 |

| Tr 18 x 4 | 17.700 | 18.000 | 15.640 | 15.905 | 13.074 | 13.500 | 1 | 4°33´ | 0.44 | 0.28 | 2 | 1434 |

| Tr 18 x 8 (P4) | 17.700 | 18.000 | 15.640 | 15.905 | 13.074 | 13.500 | 2 | 9°02´ | 0.60 | 0.43 | 2 | 1434 |

| Tr 20 x 4 | 19.700 | 20.000 | 17.640 | 17.905 | 15.074 | 15.500 | 1 | 4°03´ | 0.41 | 0.26 | 2 | 2534 |

| Tr 20 x 8 (P4) | 19.700 | 20.000 | 17.640 | 17.905 | 15.074 | 15.500 | 2 | 8°03´ | 0.58 | 0.40 | 2 | 2534 |

| Tr 20 x 20 (P5) | 19.665 | 20.000 | 17.114 | 17.394 | 14.044 | 14.500 | 4 | 20°00´ | 0.76 | 0.60 | 2.5 | 1910 |

| Tr 22 x 5 | 21.665 | 22.000 | 19.114 | 19.394 | 16.044 | 16.500 | 1 | 4°40´ | 0.45 | 0.28 | 2.5 | 3232 |

| Tr 22 x 10 (P5) | 21.665 | 22.000 | 19.114 | 19.394 | 16.044 | 16.500 | 2 | 9°16´ | 0.61 | 0.43 | 2.5 | 3232 |

| Tr 24 x 5 | 23.665 | 24.000 | 21.094 | 21.394 | 18.019 | 18.500 | 1 | 4°14´ | 0.42 | 0.27 | 2.5 | 5175 |

| Tr 24 x 10 (P5) | 23.665 | 24.000 | 21.094 | 21.394 | 18.019 | 18.500 | 2 | 8°25´ | 0.59 | 0.41 | 2.5 | 5175 |

| Tr 25 x 3 | 24.764 | 25.000 | 23.165 | 23.415 | 21.103 | 21.500 | 1 | 2°20´ | 0.29 | 0.17 | 1.5 | 9735 |

| Tr 25 x 5 | 24.665 | 25.000 | 22.094 | 22.394 | 19.019 | 19.500 | 1 | 4°03´ | 0.41 | 0.26 | 2.5 | 6423 |

| Tr 25 x 10 (P5) | 24.665 | 25.000 | 22.094 | 22.394 | 19.019 | 19.500 | 2 | 8°03´ | 0.58 | 0.40 | 2.5 | 6423 |

| Tr 25 x 25 (P5) | 24.665 | 25.000 | 22.094 | 22.394 | 19.019 | 19.500 | 5 | 19°30´ | 0.75 | 0.60 | 2.5 | 6423 |

| Tr 26 x 5 | 25.665 | 26.000 | 23.094 | 23.394 | 20.019 | 20.500 | 1 | 3°52´ | 0.40 | 0.25 | 2.5 | 7884 |

| Tr 26 x 10 (P5) | 25.665 | 26.000 | 23.094 | 23.394 | 20.019 | 20.500 | 2 | 7°42´ | 0.57 | 0.39 | 2.5 | 7884 |

| Tr 28 x 5 | 27.665 | 28.000 | 25.094 | 25.394 | 22.019 | 22.500 | 1 | 3°34´ | 0.38 | 0.23 | 2.5 | 11539 |

| Tr 28 x 10 (P5) | 27.665 | 28.000 | 25.094 | 25.394 | 22.019 | 22.500 | 2 | 7°07´ | 0.55 | 0.37 | 2.5 | 11539 |

| Tr 30 x 3 | 29.764 | 30.000 | 28.165 | 28.415 | 26.103 | 26.500 | 1 | 1°55´ | 0.25 | 0.14 | 1.5 | 22900 |

| Tr 30 x 4 | 29.700 | 30.000 | 27.640 | 27.905 | 25.074 | 25.500 | 1 | 2°36´ | 0.31 | 0.18 | 2 | 19400 |

| Tr 30 x 5 | 29.665 | 30.000 | 27.094 | 27.394 | 24.019 | 24.500 | 1 | 3°19´ | 0.36 | 0.22 | 2.5 | 16340 |

| Tr 30 x 6 | 29.625 | 30.000 | 26.547 | 26.882 | 22.463 | 23.000 | 1 | 4°03´ | 0.41 | 0.26 | 3 | 13650 |

| Tr 30 x 12 (P6) | 29.625 | 30.000 | 26.547 | 26.882 | 22.463 | 23.000 | 2 | 8°03´ | 0.58 | 0.40 | 3 | 13650 |

| Tr 30 x 30 (P5) | 29.665 | 30.000 | 27.094 | 27.394 | 24.019 | 24.500 | 6 | 19°09´ | 0.75 | 0.59 | 2.5 | 16340 |

| Tr 32 x 6 | 31.625 | 32.000 | 28.547 | 28.882 | 24.463 | 25.000 | 1 | 3°46´ | 0.39 | 0.24 | 3 | 17580 |

| Tr 32 x 12 (P6) | 31.625 | 32.000 | 28.547 | 28.882 | 24.463 | 25.000 | 2 | 7°30´ | 0.56 | 0.38 | 3 | 17580 |

| Tr 35 x 3 | 34.764 | 35.000 | 33.165 | 33.415 | 31.103 | 31.500 | 1 | 1°38´ | 0.22 | 0.12 | 1.5 | 46128 |

| Tr 35 x 4 | 34.700 | 35.000 | 32.640 | 32.905 | 30.074 | 30.500 | 1 | 2°13´ | 0.28 | 0.16 | 2 | 40150 |

| Tr 35 x 5 | 34.665 | 35.000 | 32.094 | 32.394 | 29.019 | 29.500 | 1 | 2°48´ | 0.33 | 0.19 | 2.5 | 34810 |

| Tr 35 x 6 | 34.625 | 35.000 | 31.547 | 31.882 | 27.463 | 28.000 | 1 | 3°25´ | 0.37 | 0.23 | 3 | 30000 |

| Tr 35 x 8 | 34.550 | 35.000 | 30.493 | 30.868 | 25.399 | 26.000 | 1 | 4°42´ | 0.45 | 0.29 | 4 | 21980 |

| Tr 36 x 6 | 35.625 | 36.000 | 32.547 | 32.882 | 28.463 | 29.000 | 1 | 3°19´ | 0.36 | 0.22 | 3 | 34540 |

| Tr 36 x 12 (P6) | 35.625 | 36.000 | 32.547 | 32.882 | 28.463 | 29.000 | 2 | 6°36´ | 0.53 | 0.36 | 3 | 34540 |

1) Useful effect for conversion of rotary movement to linear movement with friction coefficient f=0.1 and f=0.2.

2) Radial support dimension between screw and nut teeth.

| Diameter x Lead | d1 Major diameter tollerance 4h mm | d2 Effective or pitch dia. tollerance 7e mm | d3 Minor diameter tollerance 7h mm | Thread Starts | Lead Angle | (1) Efficiency ŋ | (2) H1 mm | I Moment of inertia mm4 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | f=0.1 | f=0.2 | |||||

| Tr 40 x 3 | 39.764 | 40.000 | 38.165 | 38.415 | 36.103 | 36.500 | 1 | 1°25´ | 0.20 | 0.11 | 1.5 | 83395 |

| Tr 40 x 4 | 39.700 | 40.000 | 37.640 | 37.905 | 35.074 | 35.500 | 1 | 1°55´ | 0.25 | 0.14 | 2 | 74290 |

| Tr 40 x 5 | 39.665 | 40.000 | 37.094 | 37.394 | 34.019 | 34.500 | 1 | 2°26´ | 0.30 | 0.17 | 2.5 | 65740 |

| Tr 40 x 6 | 39.625 | 40.000 | 36.547 | 36.882 | 32.463 | 33.000 | 1 | 2°57´ | 0.34 | 0.20 | 3 | 57950 |

| Tr 40 x 7 | 39.575 | 40.000 | 36.020 | 36.375 | 31.431 | 32.000 | 1 | 3°30´ | 0.38 | 0.23 | 3.5 | 51030 |

| Tr 40 x 8 | 39.550 | 40.000 | 35.493 | 35.868 | 30.399 | 31.000 | 1 | 4°03´ | 0.41 | 0.26 | 4 | 44560 |

| Tr 40 x 10 | 39.470 | 40.000 | 34.450 | 34.850 | 28.350 | 29.000 | 1 | 5°12´ | 0.47 | 0.31 | 5 | 31700 |

| Tr 40 x 14 (P7) | 39.575 | 40.000 | 36.020 | 36.375 | 31.431 | 32.000 | 2 | 6°58´ | 0.54 | 0.37 | 3.5 | 51030 |

| Tr 40 x 40 (P8) | 39.550 | 40.000 | 35.493 | 35.868 | 30.399 | 31.000 | 5 | 19°30´ | 0.75 | 0.60 | 4 | 44560 |

| Tr 44 x 7 | 43.575 | 44.000 | 40.020 | 40.375 | 35.431 | 36.000 | 1 | 3°09´ | 0.35 | 0.21 | 3.5 | 81820 |

| Tr 45 x 8 | 44.550 | 45.000 | 40.493 | 40.868 | 35.399 | 36.000 | 1 | 3°33´ | 0.38 | 0.23 | 4 | 81245 |

| Tr 50 x 3 | 49.764 | 50.000 | 48.150 | 48.415 | 46.084 | 46.500 | 1 | 1°08´ | 0.16 | 0.09 | 1.5 | 121400 |

| Tr 50 x 4 | 49.700 | 50.000 | 47.605 | 47.905 | 45.074 | 45.500 | 1 | 1°31´ | 0.21 | 0.12 | 2 | 202600 |

| Tr 50 x 5 | 49.665 | 50.000 | 47.094 | 47.394 | 44.019 | 44.500 | 1 | 1°55´ | 0.25 | 0.14 | 2.5 | 184300 |

| Tr 50 x 6 | 49.625 | 50.000 | 46.547 | 46.882 | 42.463 | 43.000 | 1 | 2°20´ | 0.29 | 0.17 | 3 | 167240 |

| Tr 50 x 8 | 49.550 | 50.000 | 45.468 | 45.868 | 40.368 | 41.000 | 1 | 3°10´ | 0.35 | 0.21 | 4 | 136930 |

| Tr 50 x 10 | 49.470 | 50.000 | 44.425 | 44.850 | 38.319 | 39.000 | 1 | 4°03´ | 0.41 | 0.26 | 5 | 105834 |

| Tr 55 x 9 | 54.500 | 55.000 | 49.935 | 50.360 | 44.329 | 45.000 | 1 | 3°15´ | 0.36 | 0.22 | 4.5 | 189550 |

| Tr 60 x 6 | 59.625 | 60.000 | 56.547 | 56.882 | 52.463 | 53.000 | 1 | 1°55´ | 0.25 | 0.14 | 3 | 386240 |

| Tr 60 x 7 | 59.575 | 60.000 | 56.020 | 56.375 | 51.431 | 52.000 | 1 | 2°16´ | 0.28 | 0.16 | 3.5 | 343450 |

| Tr 60 x 9 | 59.500 | 60.000 | 54.935 | 55.360 | 49.329 | 50.000 | 1 | 2°57´ | 0.34 | 0.20 | 4.5 | 302600 |

| Tr 70 x 10 | 69.470 | 70.000 | 64.425 | 64.850 | 58.319 | 59.000 | 1 | 2°48´ | 0.33 | 0.19 | 5 | 587540 |

| Tr 80 x 10 | 79.470 | 80.000 | 74.425 | 74.850 | 68.319 | 69.000 | 1 | 2°26´ | 0.30 | 0.17 | 5 | 1069390 |

| Tr 90 x 12 | 89.400 | 90.000 | 83.335 | 83.830 | 76.246 | 77.000 | 1 | 2°36´ | 0.31 | 0.18 | 6 | 1658969 |

| Tr 95 x 16 | 94.290 | 95.000 | 86.250 | 86.810 | 76.110 | 77.000 | 1 | 3°21´ | 0.37 | 0.22 | 8 | 1647164 |

| Tr 100 x 12 | 99.400 | 100.000 | 93.330 | 93.830 | 86.215 | 87.000 | 1 | 2°19´ | 0.29 | 0.17 | 6 | 2712072 |

| Tr 100 x 16 | 99.290 | 100.000 | 91.250 | 91.810 | 81.110 | 82.000 | 1 | 3°10´ | 0.35 | 0.21 | 8 | 2124553 |

| Tr 120 x 14 | 119.330 | 120.000 | 112.290 | 112.820 | 103.157 | 104.00 | 1 | 2°16´ | 0.28 | 0.16 | 7 | 5558591 |

| Tr 120 x 16 | 119.290 | 120.000 | 111.250 | 111.810 | 101.110 | 102.00 | 1 | 2°36´ | 0.31 | 0.16 | 8 | 5130342 |

| Tr 140 x 14 | 139.330 | 140.000 | 132.290 | 132.820 | 123.157 | 124.00 | 1 | 1°55´ | 0.25 | 0.14 | 7 | 11292921 |

| Tr 160 x 16 | 159.290 | 160.000 | 151.250 | 151.810 | 141.110 | 142.00 | 1 | 1°55´ | 0.25 | 0.14 | 8 | 19462609 |

1) Useful effect for conversion of rotary movement to linear movement with friction coefficient f=0.1 and f=0.2.

2) Radial support dimension between screw and nut teeth.

| Diameter x Lead | D4 Major diameter tollerance H mm | D2 Effective or pitch dia. tollerance 7H mm | D1 Minor diameter tollerance 4H mm | Thread Starts | Radial play between screw & nut | Axial play between screw & nut | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | ||

| Tr 10 x 2 | 10.5 | 9.000 | 9.250 | 8.000 | 8.236 | 1 | 0.071 | 0.511 | 0.019 | 0.137 | |

| Tr 10 x 3 | 10.5 | 8.500 | 8.780 | 7.000 | 7.315 | 1 | 0.085 | 0.577 | 0.023 | 0.155 | |

| Tr 10 x 4 (P2) | 10.5 | 9.000 | 9.250 | 8.000 | 8.236 | 2 | 0.071 | 0.511 | 0.019 | 0.137 | |

| Tr 12 x 3 | 12.5 | 10.500 | 10.800 | 9.000 | 9.315 | 1 | 0.085 | 0.609 | 0.023 | 0.163 | |

| Tr 12 x 6 (P3) | 12.5 | 10.500 | 10.800 | 9.000 | 9.315 | 2 | 0.085 | 0.609 | 0.023 | 0.163 | |

| Tr 14 x 3 | 14.5 | 12.500 | 12.800 | 11.000 | 11.315 | 1 | 0.085 | 0.609 | 0.023 | 0.163 | |

| Tr 14 x 4 | 14.5 | 12.000 | 12.355 | 10.000 | 10.375 | 1 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 14 x 6 (P3) | 14.5 | 12.500 | 12.800 | 11.000 | 11.315 | 2 | 0.085 | 0.609 | 0.023 | 0.163 | |

| Tr 16 x 4 | 16.5 | 14.000 | 14.355 | 12.000 | 12.375 | 1 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 16 x 8 (P4) | 16.5 | 14.000 | 14.355 | 12.000 | 12.375 | 2 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 18 x 4 | 18.5 | 16.000 | 16.355 | 14.000 | 14.375 | 1 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 18 x 8 (P4) | 18.5 | 16.000 | 16.355 | 14.000 | 14.375 | 2 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 20 x 4 | 20.5 | 18.000 | 18.355 | 16.000 | 16.375 | 1 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 20 x 8 (P4) | 20.5 | 18.000 | 18.355 | 16.000 | 16.375 | 2 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 20 x 20 (P5) | 20.5 | 17.500 | 17.875 | 15.000 | 15.450 | 4 | 0.106 | 0.761 | 0.028 | 0.204 | |

| Tr 22 x 5 | 22.5 | 19.500 | 19.875 | 17.000 | 17.450 | 1 | 0.106 | 0.761 | 0.028 | 0.204 | |

| Tr 22 x 10 (P5) | 22.5 | 19.500 | 19.875 | 17.000 | 17.450 | 2 | 0.106 | 0.761 | 0.028 | 0.204 | |

| Tr 24 x 5 | 24.5 | 21.500 | 21.900 | 19.000 | 19.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 24 x 10 (P5) | 24.5 | 21.500 | 21.900 | 19.000 | 19.450 | 2 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 25 x 3 | 25.5 | 23.500 | 23.835 | 22.000 | 22.315 | 1 | 0.085 | 0.67 | 0.023 | 0.180 | |

| Tr 25 x 5 | 25.5 | 22.500 | 22.900 | 20.000 | 20.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 25 x 10 (P5) | 25.5 | 22.500 | 22.900 | 20.000 | 20.450 | 2 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 25 x 25 (P5) | 25.5 | 22.500 | 22.900 | 20.000 | 20.450 | 5 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 26 x 5 | 26.5 | 23.500 | 23.900 | 21.000 | 21.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 26 x 10 (P5) | 26.5 | 23.500 | 23.900 | 21.000 | 21.450 | 2 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 28 x 5 | 28.5 | 25.500 | 25.900 | 23.000 | 23.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 28 x 10 (P5) | 28.5 | 25.500 | 25.900 | 23.000 | 23.450 | 2 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 30 x 3 | 30.5 | 28.500 | 28.835 | 27.000 | 27.315 | 1 | 0.085 | 0.67 | 0.023 | 0.180 | |

| Tr 30 x 4 | 30.5 | 28.000 | 28.855 | 26.000 | 26.375 | 1 | 0.095 | 1.215 | 0.025 | 0.326 | |

| Tr 30 x 5 | 30.5 | 27.500 | 27.900 | 25.000 | 25.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 30 x 6 | 31 | 27.000 | 27.450 | 24.000 | 24.500 | 1 | 0.118 | 0.903 | 0.032 | 0.242 | |

| Tr 30 x 12 (P6) | 31 | 27.000 | 27.450 | 24.000 | 24.500 | 2 | 0.118 | 0.903 | 0.032 | 0.242 | |

| Tr 30 x 30 (P5) | 30.5 | 27.500 | 27.900 | 25.000 | 25.450 | 6 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 32 x 6 | 33 | 29.000 | 29.450 | 26.000 | 26.500 | 1 | 0.118 | 0.903 | 0.032 | 0.242 | |

| Tr 32 x 12 (P6) | 33 | 29.000 | 29.450 | 26.000 | 26.500 | 2 | 0.118 | 0.903 | 0.032 | 0.242 | |

| Tr 35 x 3 | 35.5 | 33.500 | 33.835 | 32.000 | 32.315 | 1 | 0.085 | 0.67 | 0.023 | 0.180 | |

| Tr 35 x 4 | 35.5 | 33.000 | 33.355 | 31.000 | 31.375 | 1 | 0.095 | 0.715 | 0.025 | 0.192 | |

| Tr 35 x 5 | 25.5 | 32.500 | 32.900 | 30.000 | 30.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 | |

| Tr 35 x 6 | 36 | 32.000 | 32.450 | 29.000 | 29.500 | 1 | 0.118 | 0.903 | 0.032 | 0.242 | |

| Tr 35 x 8 | 36 | 31.000 | 31.500 | 27.000 | 27.630 | 1 | 0.132 | 1.007 | 0.035 | 0.270 | |

| Tr 36 x 6 | 37 | 33.000 | 33.450 | 30.000 | 30.500 | 1 | 0.118 | 0.903 | 0.032 | 0.242 | |

| Tr 38 x 12 (P6) | 37 | 33.000 | 33.450 | 30.000 | 30.500 | 2 | 0.118 | 0.903 | 0.032 | 0.242 | |

| Diameter x Lead | D4 Major diameter tollerance H mm | D2 Effective or pitch dia. tollerance 7H mm | D1 Minor diameter tollerance 4H mm | Thread Starts | Radial play between screw & nut | Axial play between screw & nut | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| min.max. | min. | max. | min. | max. | min. | max. | min. | max. | ||

| Tr 40 x 3 | 40.5 | 38.500 | 38.835 | 37.000 | 37.315 | 1 | 0.085 | 0.67 | 0.023 | 0.18 |

| Tr 40 x 4 | 40.5 | 38.000 | 38.355 | 36.000 | 36.375 | 1 | 0.095 | 0.715 | 0.025 | 0.192 |

| Tr 40 x 5 | 40.5 | 37.500 | 37.900 | 35.000 | 35.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 |

| Tr 40 x 6 | 41 | 37.000 | 37.450 | 34.000 | 34.500 | 1 | 0.118 | 0.903 | 0.032 | 0.242 |

| Tr 40 x 7 | 41 | 36.500 | 36.975 | 33.000 | 33.560 | 1 | 0.125 | 0.955 | 0.033 | 0.256 |

| Tr 40 x 8 | 41 | 36.000 | 36.500 | 32.000 | 32.630 | 1 | 0.132 | 1.007 | 0.035 | 0.27 |

| Tr 40 x 10 | 41 | 35.000 | 35.530 | 30.000 | 30.710 | 1 | 0.15 | 1.08 | 0.04 | 0.289 |

| Tr 40 x 14 (P7) | 41 | 36.500 | 36.975 | 33.000 | 33.560 | 2 | 0.125 | 0.955 | 0.033 | 0.256 |

| Tr 40 x 40 (P8) | 41 | 36.000 | 36.500 | 32.000 | 32.630 | 5 | 0.132 | 1.007 | 0.035 | 0.27 |

| Tr 44 x 7 | 45 | 40.500 | 40.975 | 37.000 | 37.560 | 1 | 0.125 | 0.955 | 0.033 | 0.256 |

| Tr 45 x 8 | 46 | 41.000 | 41.500 | 37.000 | 37.630 | 1 | 0.132 | 1.007 | 0.035 | 0.27 |

| Tr 50 x 3 | 50.5 | 48.500 | 48.855 | 47.000 | 47.315 | 1 | 0.085 | 0.705 | 0.023 | 0.189 |

| Tr 50 x 4 | 50.5 | 48.000 | 48.400 | 46.000 | 46.375 | 1 | 0.095 | 0.795 | 0.025 | 0.213 |

| Tr 50 x 5 | 50.5 | 47.500 | 47.900 | 45.000 | 45.450 | 1 | 0.106 | 0.806 | 0.028 | 0.216 |

| Tr 50 x 6 | 51 | 47.000 | 47.450 | 44.000 | 44.500 | 1 | 0.118 | 0.903 | 0.032 | 0.242 |

| Tr 50 x 8 | 51 | 46.000 | 46.530 | 42.000 | 42.630 | 1 | 0.132 | 1.062 | 0.035 | 0.285 |

| Tr 50 x 10 | 51 | 45.000 | 45.560 | 40.000 | 40.710 | 1 | 0.15 | 1.135 | 0.04 | 0.304 |

| Tr 55 x 9 | 56 | 50.500 | 51.060 | 46.000 | 46.670 | 1 | 0.14 | 1.125 | 0.038 | 0.301 |

| Tr 60 x 6 | 61 | 57.000 | 57.450 | 54.000 | 54.500 | 1 | 0.118 | 0.903 | 0.032 | 0.242 |

| Tr 60 x 7 | 61 | 56.500 | 56.975 | 53.000 | 53.560 | 1 | 0.125 | 0.955 | 0.033 | 0.256 |

| Tr 60 x 9 | 61 | 55.500 | 56.060 | 51.000 | 51.670 | 1 | 0.14 | 1.125 | 0.038 | 0.301 |

| Tr 70 x 10 | 71 | 65.000 | 65.560 | 60.000 | 60.710 | 1 | 0.15 | 1.135 | 0.04 | 0.304 |

| Tr 80 x 10 | 81 | 75.000 | 75.560 | 70.000 | 70.710 | 1 | 0.15 | 1.135 | 0.04 | 0.304 |

| Tr 90 x 12 | 91 | 84.000 | 84.630 | 78.000 | 78.800 | 1 | 0.17 | 1.295 | 0.046 | 0.347 |

| Tr 95 x 16 | 97 | 87.000 | 87.750 | 79.000 | 80.000 | 1 | 0.19 | 1.5 | 0.051 | 0.402 |

| Tr 100 x 12 | 101 | 94.000 | 94.670 | 88.000 | 88.800 | 1 | 0.17 | 1.34 | 0.046 | 0.359 |

| Tr 100 x 16 | 102 | 92.000 | 92.750 | 84.000 | 85.000 | 1 | 0.19 | 1.5 | 0.051 | 0.402 |

| Tr 120 x 14 | 122 | 113.000 | 113.710 | 106.00 | 106.900 | 1 | 0.18 | 1.42 | 0.048 | 0.38 |

| Tr 120 x 16 | 122 | 112.000 | 112.750 | 104.00 | 105.000 | 1 | 0.19 | 1.5 | 0.051 | 0.402 |

| Tr 140 x 14 | 142 | 133.000 | 133.710 | 126.00 | 126.900 | 1 | 0.18 | 1.42 | 0.048 | 0.38 |

| Tr 160 x 16 | 162 | 152.000 | 152.750 | 144.00 | 145.000 | 1 | 0.19 | 1.5 | 0.051 | 0.402 |

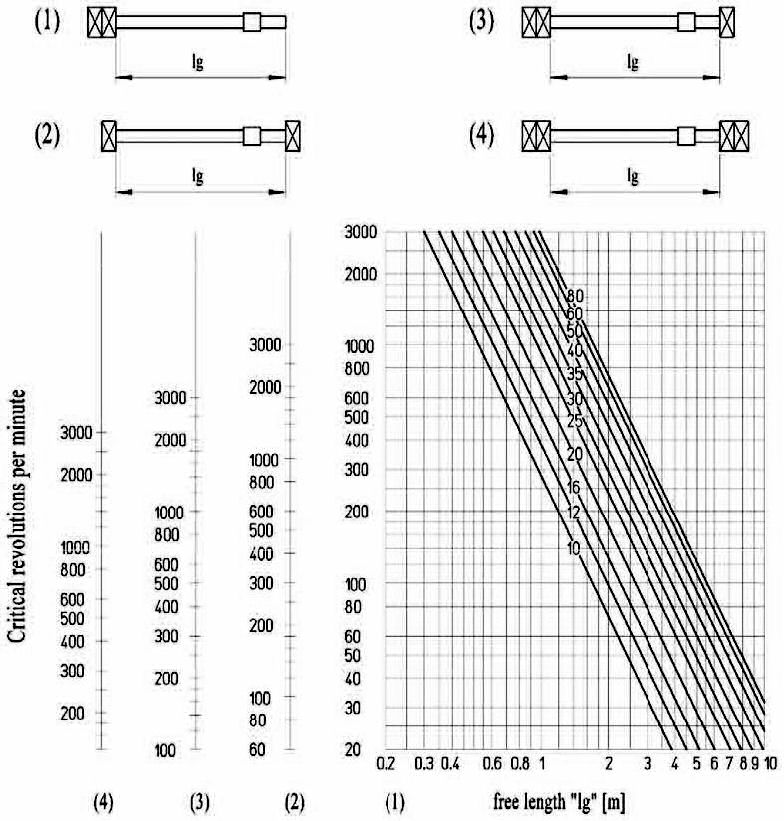

The critical revolutions per minute is the rotating speed at which screw vibrations appear. This rotation speed must never be reached because the vibrations cause serious operating irregularities. Critical rpm depend on screw diameter, end constraints (bearings), free length "lg" and from the assembly accuracy. For values shown in Graph 2 assume a minimum safety factor related to the assembly accuracy as per following chart:

Chart No1 Assembly Accuracy Coefficient: | ||

|---|---|---|

| Assembly Accuracy | Conditions | Safety Coefficient |

| Good assembly accuracy: -Nut alignment to screw within 0.05mm | Bearing and nut seats obtained from CNC lathe onto an already finished structure. | 1.3 -1.6 |

| Average assembly accuracy: -Nut alignment to screw within 0.10mm | Bearing and nut seats processed on parts which are then assembled together. Alignments are checked by comparators with extreme care after mounting | 1.7 -2.5 |