Electroforms are manufactured by a process of electrodeposition; by building thin layers of metal onto a precision machined mandrel with the quality and dimensional accuracy being of paramount importance. Then, by refining the electroforming process, parts with unusual shapes, thin walls, deep crevices and other design features can be controlled to ensure the highest part quality.

With the specialized electroforming process, most custom electroforms require no significant tooling, which can allow for several prototype variations to be supplied and evaluated, as opposed to being locked into a design by expensive dies or moulds. A major advantage of the electroforming process is the ability to provide close tolerance steps and dimensions not easily produced with stamping or other mechanical processes.

A major advantage of the electroforming process is the ability to provide close tolerance steps and dimensions not easily produced with stamping or other mechanical processes.

The designs are limited only by your imagination.

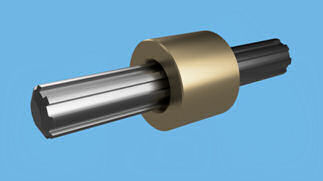

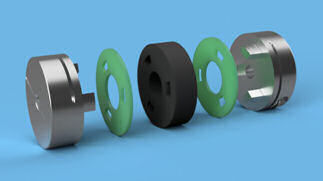

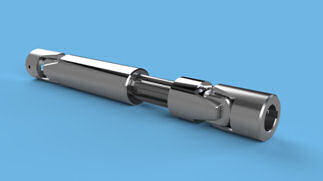

(Flexible Torque Transmission) - Utilizing the low inertia, zero backlash and high torsional rigidity characteristics of a bellows a range of flexible couplings is available. Inherently, absorbing angular and parallel shaft misalignments in combination with axial movements, while precisely transmitting motion and torque is there key strengths. Ideally suited for coupling to encoders and resolvers in precision positioning applications.

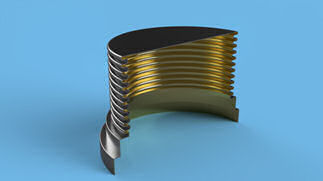

(Rigid, Lightweight Structural Forms) With a truly refined process, custom designed Electroforms and thin walled hollow metal components, for use in a myriad of high tech applications can be supplied. These often unique Electroforms can be used as moulds, cold shields or radiation shields, waveguides, for precision tubing, and light weight structurally rigid components. They can be made as small as 0.5mm (0.020 in) diameter out of nickel, copper, gold or silver, or a combination of all.

The technology on offer can and has been used on a whole range of applications in aerospace, medical equipment, electronic chip manufacture, microwave applications, cryogenic cooling and PCB automatic testing activity to name a few. Our quality is of the best, and where miniature metal bellows are concerned, there are none that compete with bellow diameters under 6 mm and, on request, we can supply down to diameters of 0.07 mm. It is not so much a product range that we offer but a technology concept, which can be measured against other more traditional methods in both quality but more importantly with regard to cost effectiveness.

(Dynamic Resilient Connection) - miniature bellows contacts are ideal for applications where contact with a delicate component or material is required. By design the contacts have low insertion forces, low insertion losses, and extremely low D.C. resistance. They have been designed to provide lifetime spring and force repeatability. Our contacts minimize shock and vibration in dynamic applications, and assist in overcoming tolerance build-up and misalignment problems in critical assemblies.

The process begins with a piece of aluminium stock or bar

Next the internal geometry of the electroform or bellows is machined into the aluminium. This machined part is called a mandrel

After inspection, nickel, copper, gold, silver or combinations thereof are electrodeposited onto the mandrel to precise wall thickness

Following post-plate inspection, the plated mandrel is trimmed to produce the desired end configuration and dimensions

Finally, the aluminium mandrel is dissolved in caustic solution, leaving behind the completed electroform or bellows. At this point special finishes or coatings may be applied.

(Flexible electrical contacts) Interconnectric® contacts are used in critical applications where contact with a delicate component or material is required; they can be used individually or as pairs especially where reliability and flexibility are a requirement. These unique contacts come with either a convex conical or concave conical tip, which when paired, will allow them to self align at interconnection. Interconnectric® contacts will minimize shock and vibration in dynamic applications and will help overcome misalignment and tolerance buildup problems in critical assemblies. Interconnectric® contacts allow the designer a less expensive alternative to high cost assembly components with tight tolerances.

Since Bellows are flexible in that they can bend, stretch, and compress, they can also be designed to be hermetically leak tight and to withstand a specific applied pressure. Combining these capabilities makes bellows ideal flexible seals in valves eliminating the need for O-rings to seal the valve stem.

With a unique patented process a hollow electroform with internal baffles can be produced. These integral baffles replace the need for costly secondary assembly operations, whilst providing structural integrity along with minimal weight. The designs of baffle electroforms are used primarily for components known as cold shields or radiation shields. The aperture openings in the baffles can be cut to any shape and orientation, so that the baffled electroform will filter the “light” radiation passing through it, by physically blocking wavelengths of light while not blocking others. These electroforms are Gold plated on the exterior for reflectivity and blackened on the interior for absorption, filtering out the unwanted frequencies of the visible and nonvisible light spectrum as light passes through.

As the name suggests, electroformed bellows can be designed to compensate for the changes in volume of a fluid in a sealed container. As the fluid expands or contracts, with changes in temperature, the electroformed bellows will compensate for these changes in a predetermined manner.

Quite simply converts temperature change into a linear motion. Utilizing a custom bellows assembly the bellows is filled with an engineered fluid with a known coefficient of expansion and sealed. As the fluid heats up or cools, its volume will expand or contract, which translates directly into calculable linear deflection.

Utilizing a bellows to dampen pressure spikes in fluids. Equating them to a spring-loaded piston, but without any seams or seals to worry about, the flexibility of the bellows allows the assembly to compensate for volumetric changes due to sudden pressure surges. The bellows will respond to changes in pressure by either compressing or extending effectively absorbing the “force” of the pressure surge.

ABSSAC Ltd, E1A The Enterprise Centre, Enterprise Way,

Evesham, Worcestershire. United Kingdom. WR11 1GS

Call: 01386 421 005

Email: sales@abssac.co.uk

Visit: www.abssac.co.uk