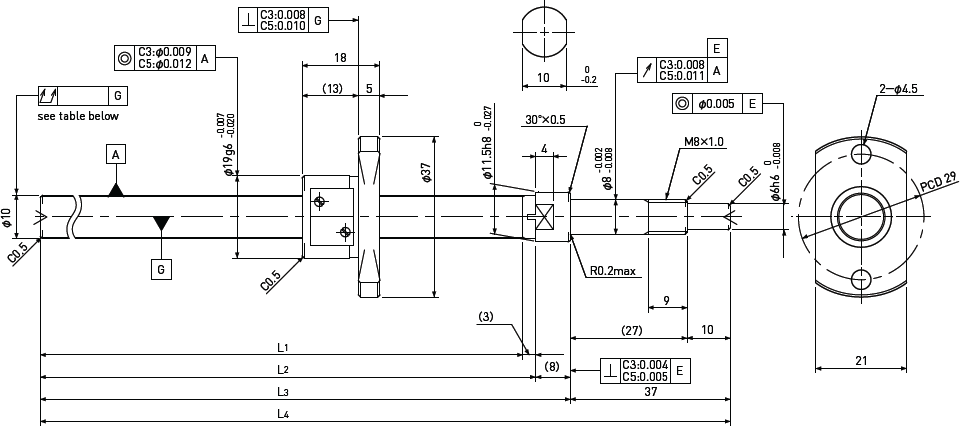

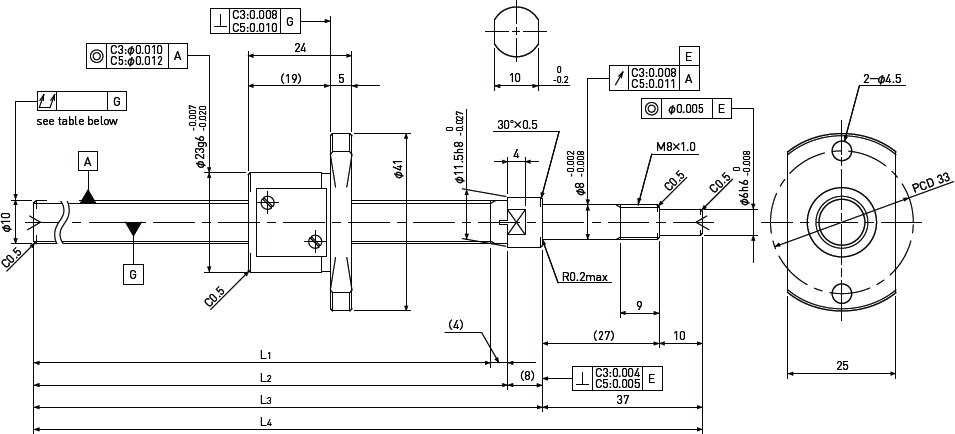

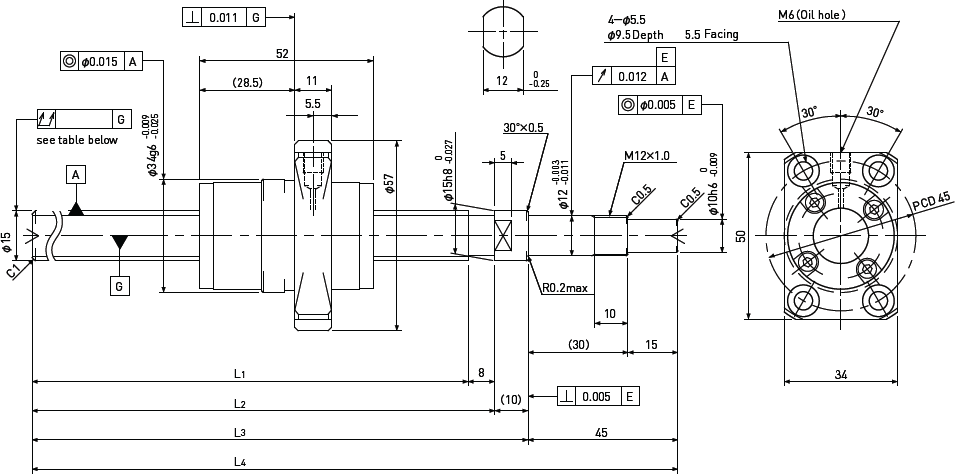

Precision Ball Screws which are accuracy C3, C5 and have machined shaft end at fixed side in advance are available. Short delivery is available by machining supported end in accordance with customer's request.

| Unit : mm | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lead | ||||||||||||

| Shaft dia. | 0.5 | 1 | 2 | 2.5 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 |

| 3 | • | • | ||||||||||

| 4 | • | • | ||||||||||

| 5 | • | |||||||||||

| 6 | • | • | • | • | • | |||||||

| 8 | • | • | • | • | • | • | • | |||||

| 10 | • | • | • | • | • | • | ||||||

| 12 | • | • | ||||||||||

| 14 | • | • | ||||||||||

| 15 | • | • | • | |||||||||

Accuracy grade of SG series (Standardized Precision Ball Screws) are based on JIS C3 and JIS C5. According to accuracy grade, Axial play 0 (Preload: C3) and 0.005mm or less (C5) are in stock.

SG series (Standardized Precision Ball Screws) consists of Shaft and Nut materials SCM415 (Carburizing and quenching) and Surface hardness is HRC58~62.

SG series(Standardized Precision Ball Screws) without end-journal machining will be applied with anti-rust oil for rust prevention.

Anti-rust oil does not have lubricating function so that please apply Grease or lubrication oil when using the Ball Screws.

If there is no specific instruction, ABSSAC would recommend our original Grease (MSG No.2) as standard lubricant.

Please feel free to contact us.

It will be a customized product other than the above. Please ask ABSSAC.

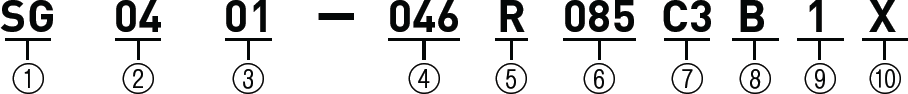

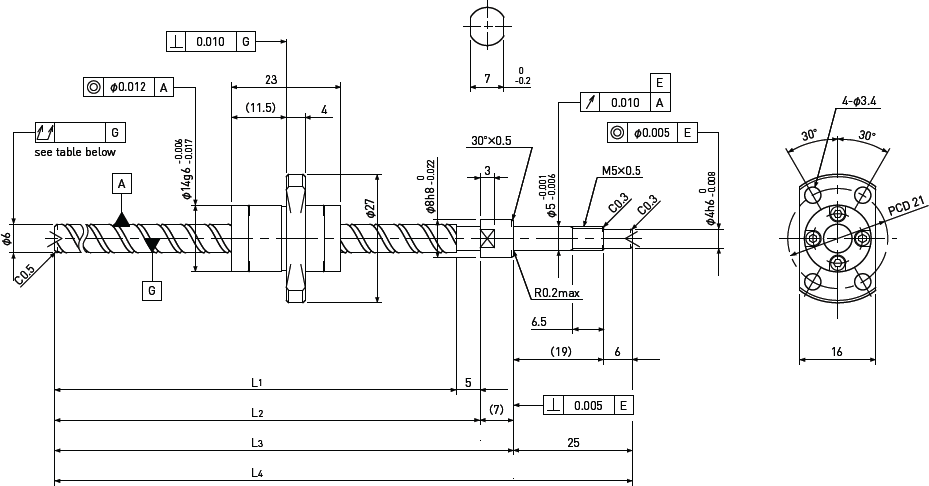

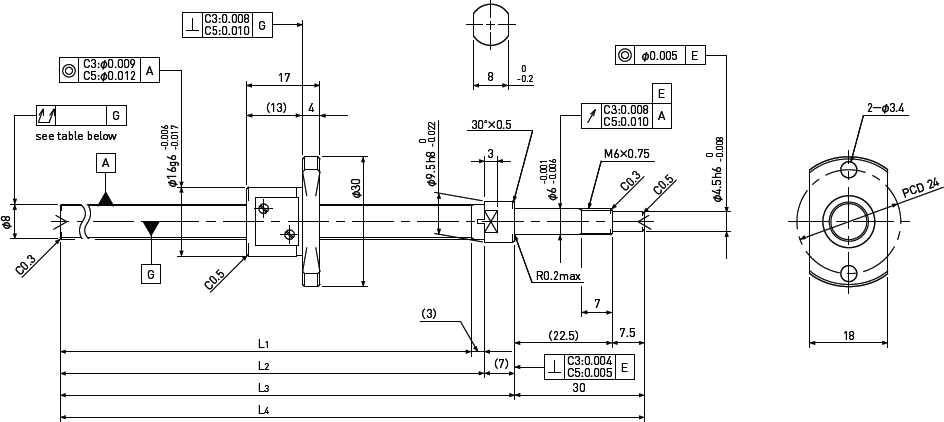

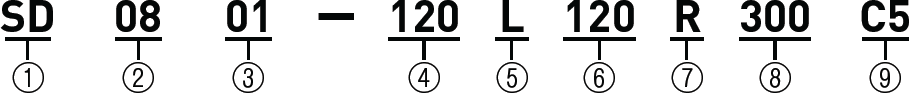

Please use model number below when additional end-journal machining is requested.

| Standard products in stock SG series | |||

|---|---|---|---|

SG0300.5 | Shaft dia. ∅3 | Lead 0.5mm | C3 |

| Unit : mm | ||||

|---|---|---|---|---|

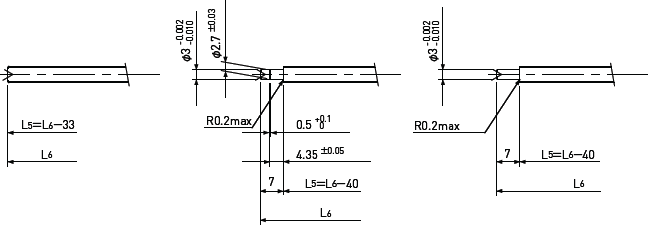

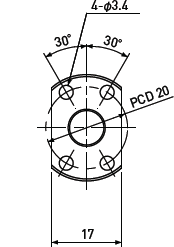

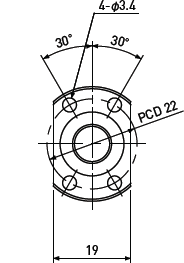

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅0.4 | A-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅2.6 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

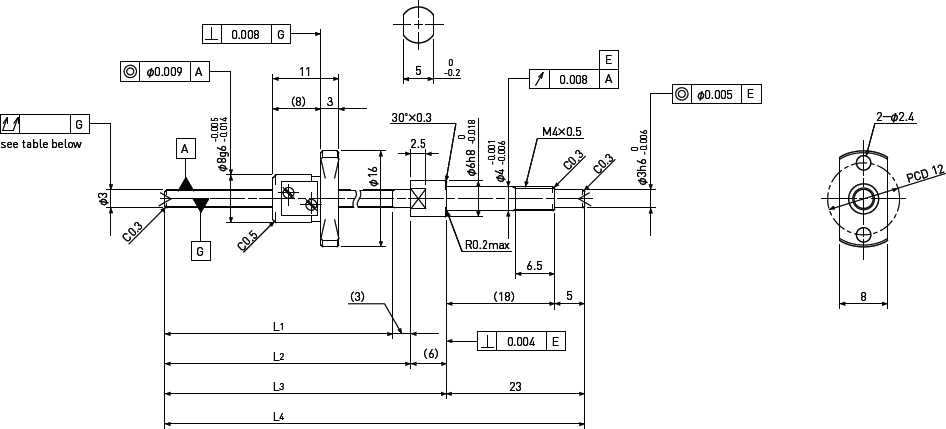

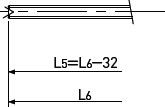

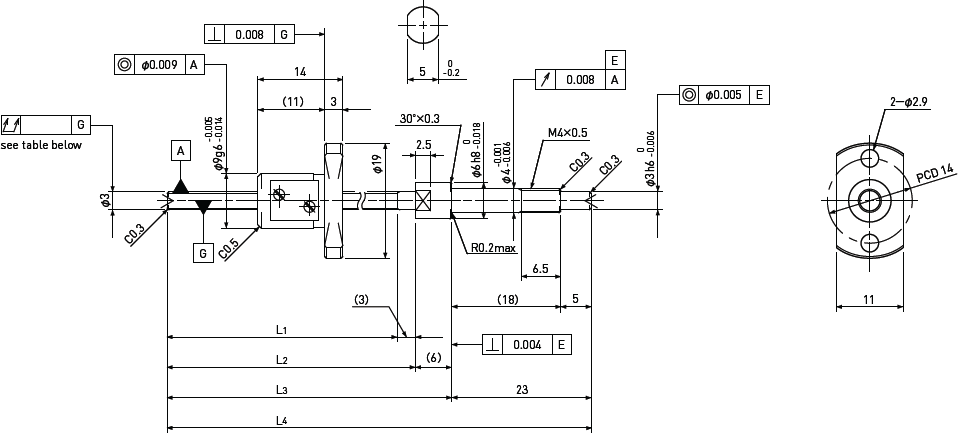

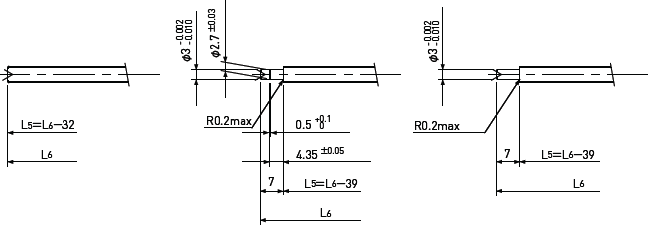

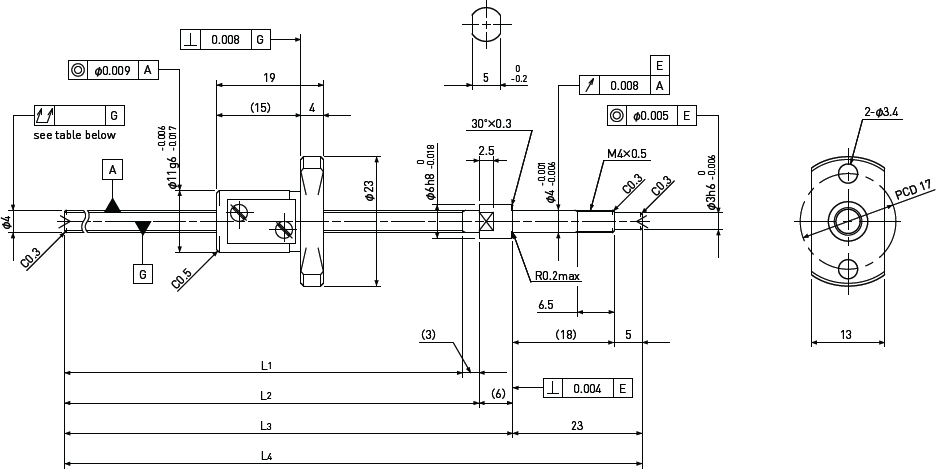

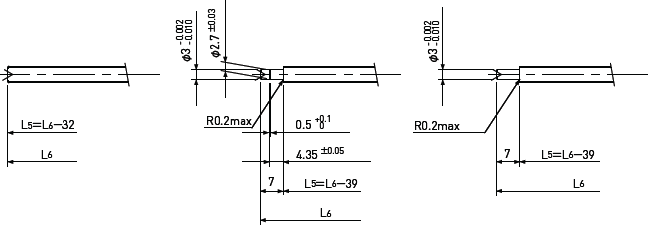

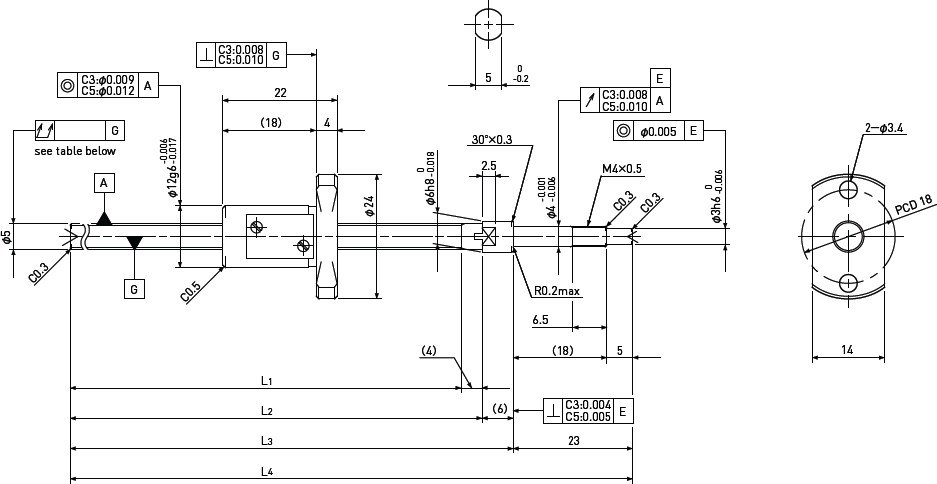

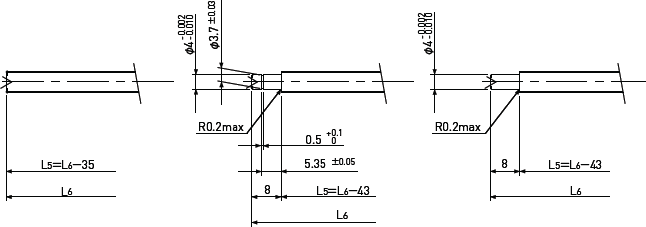

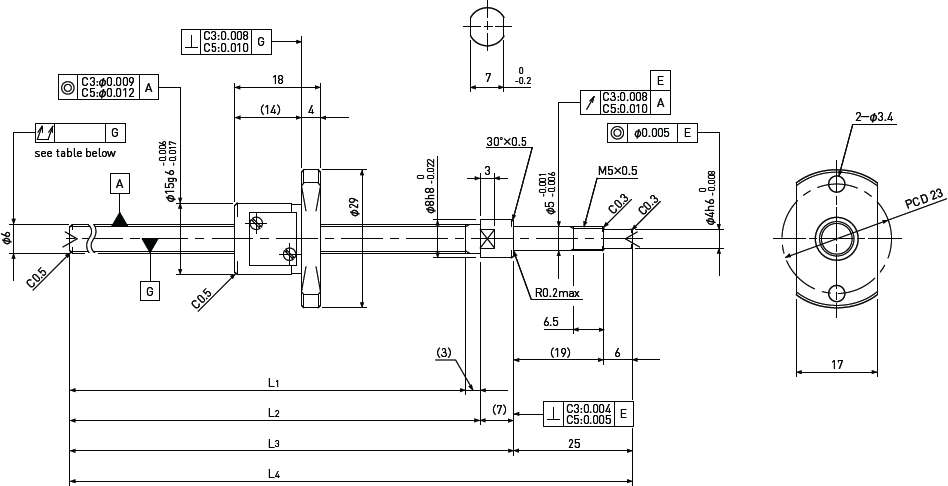

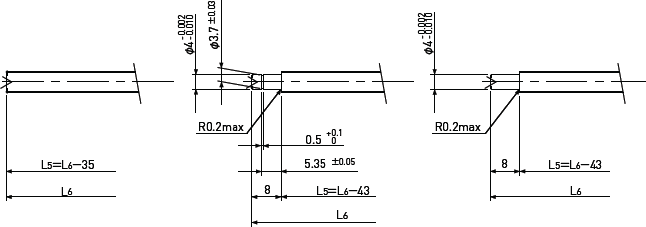

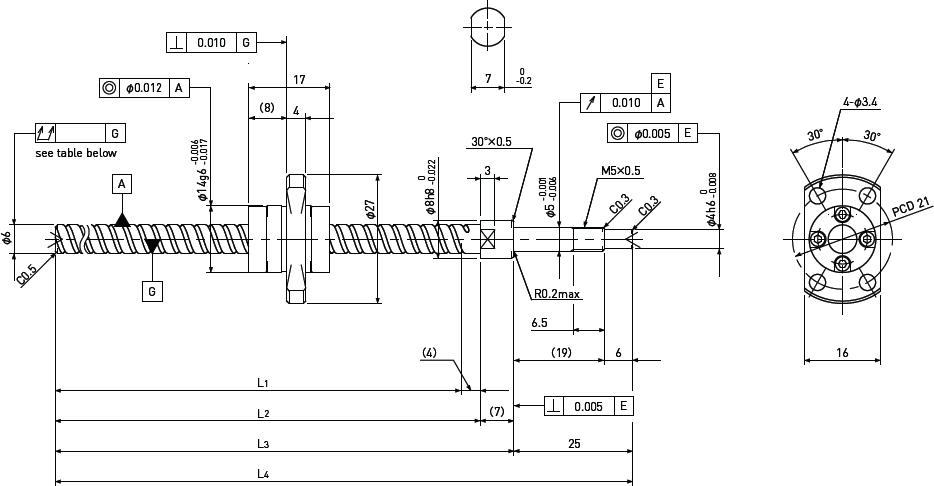

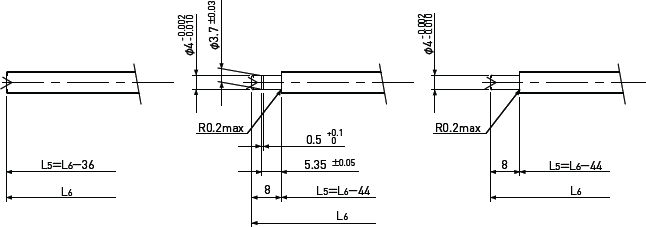

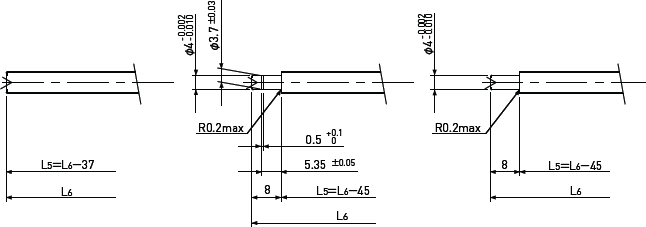

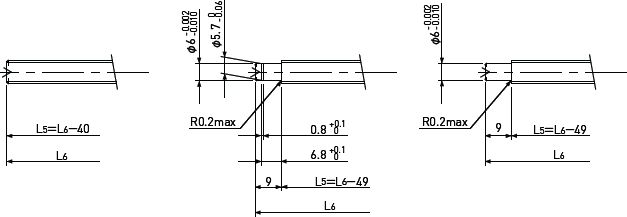

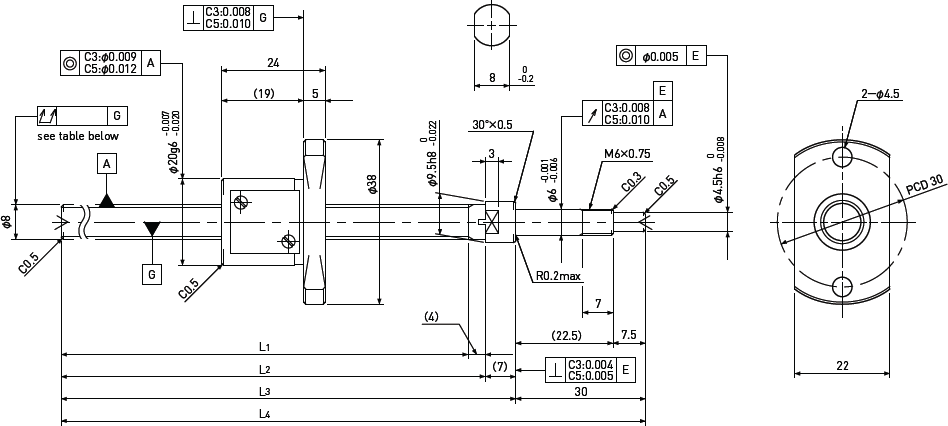

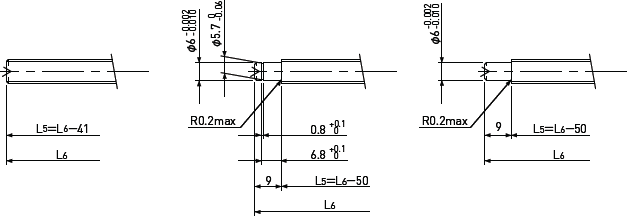

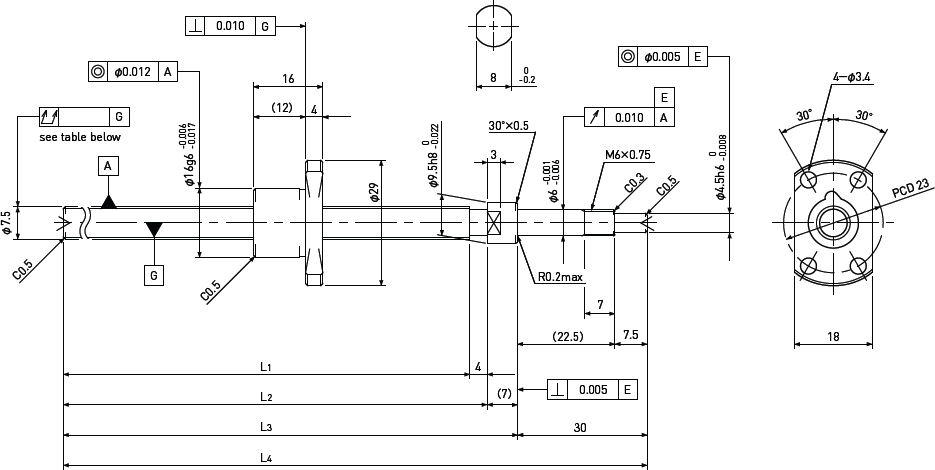

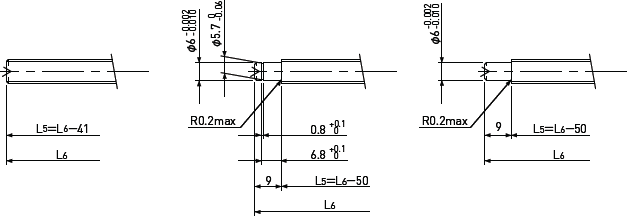

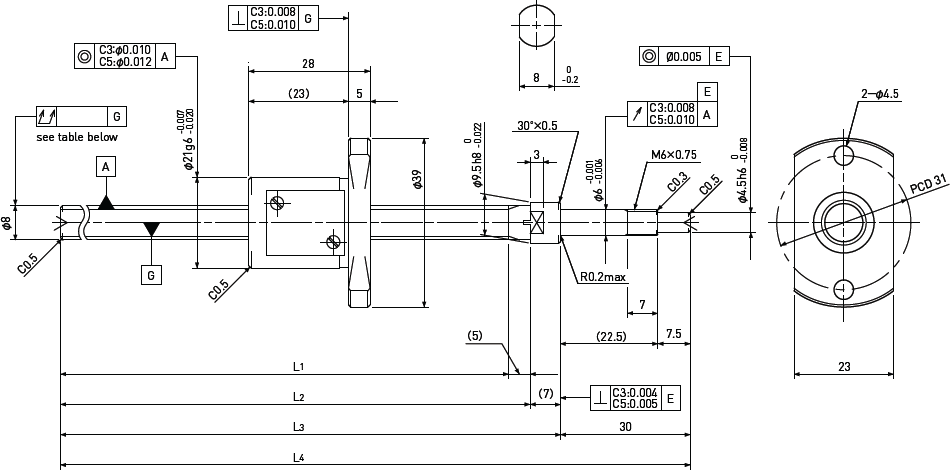

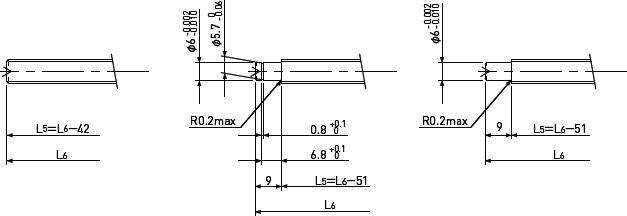

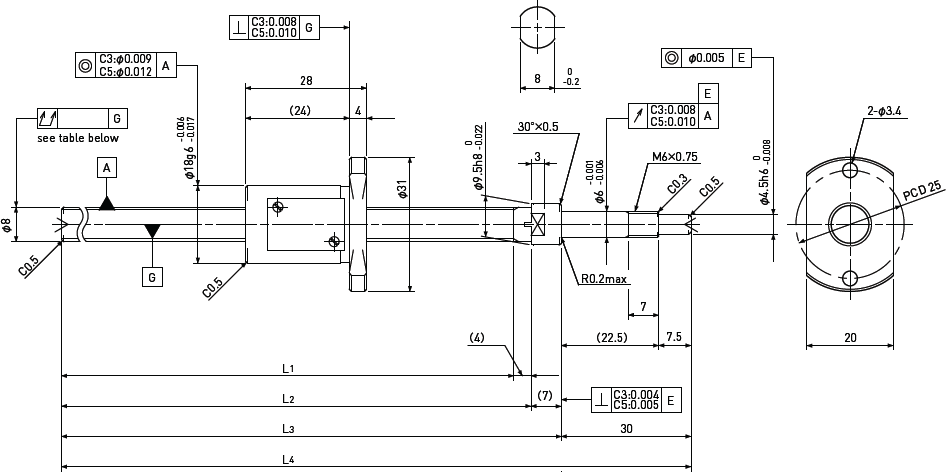

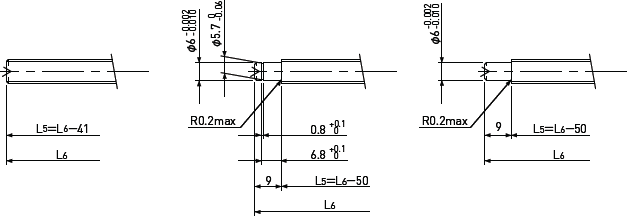

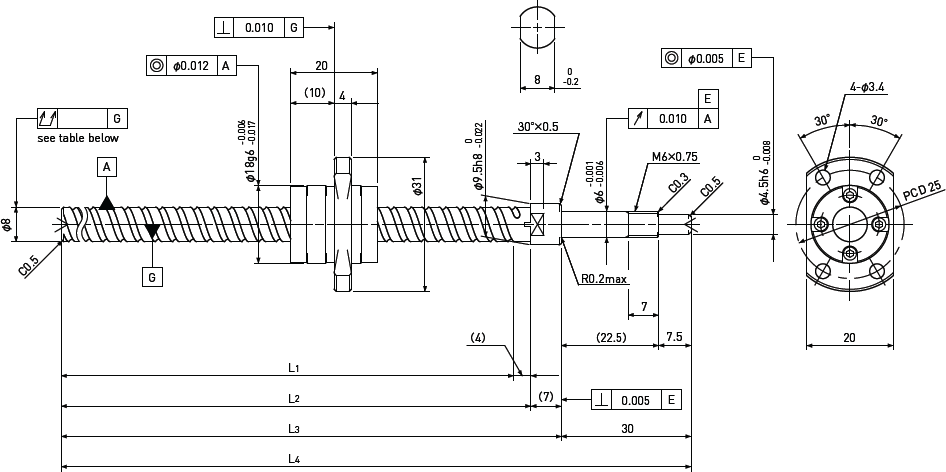

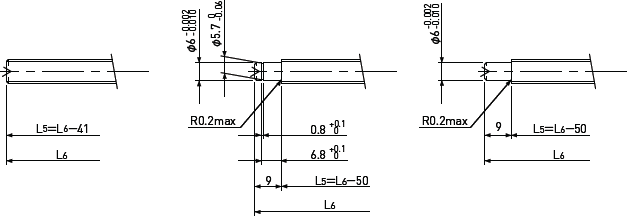

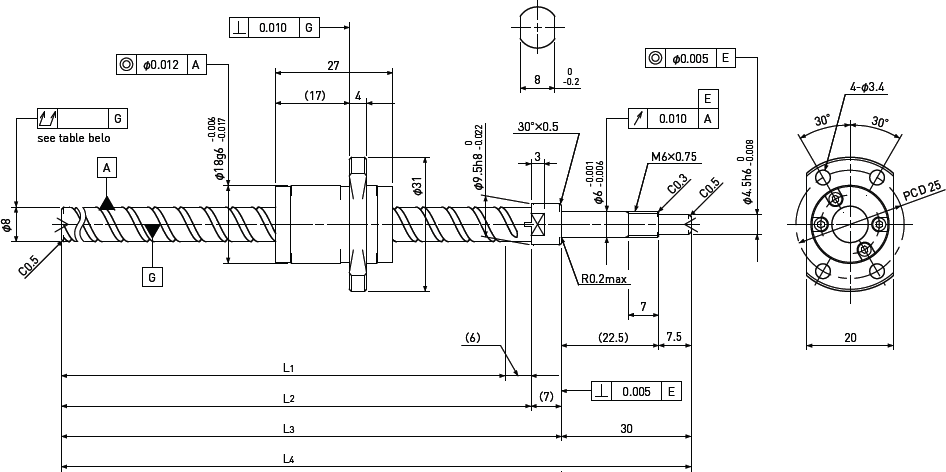

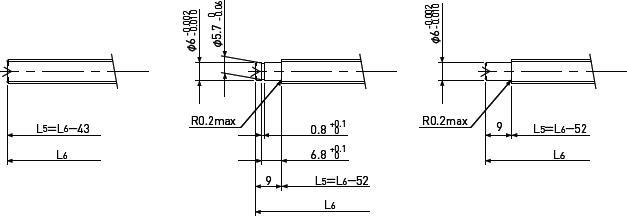

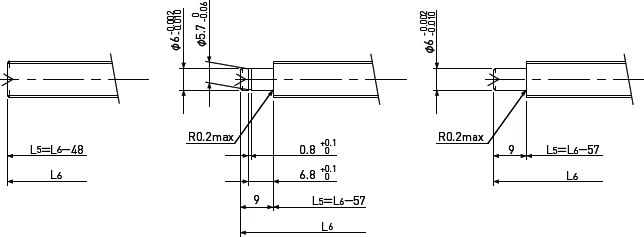

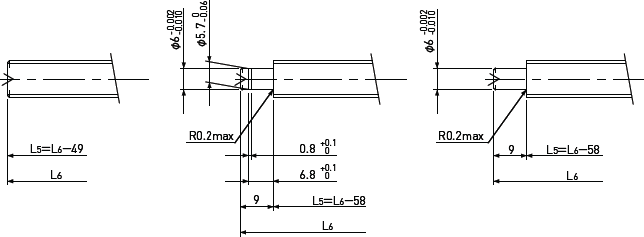

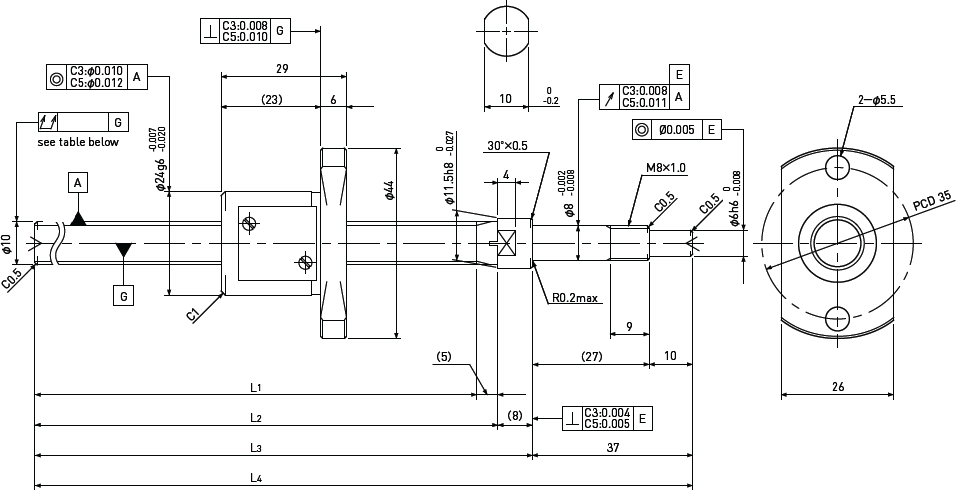

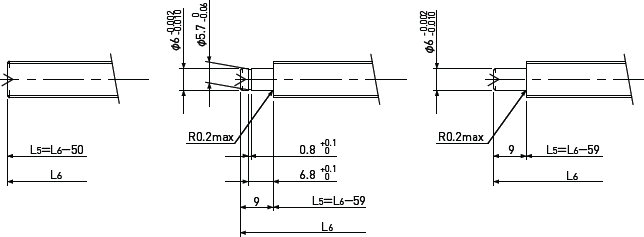

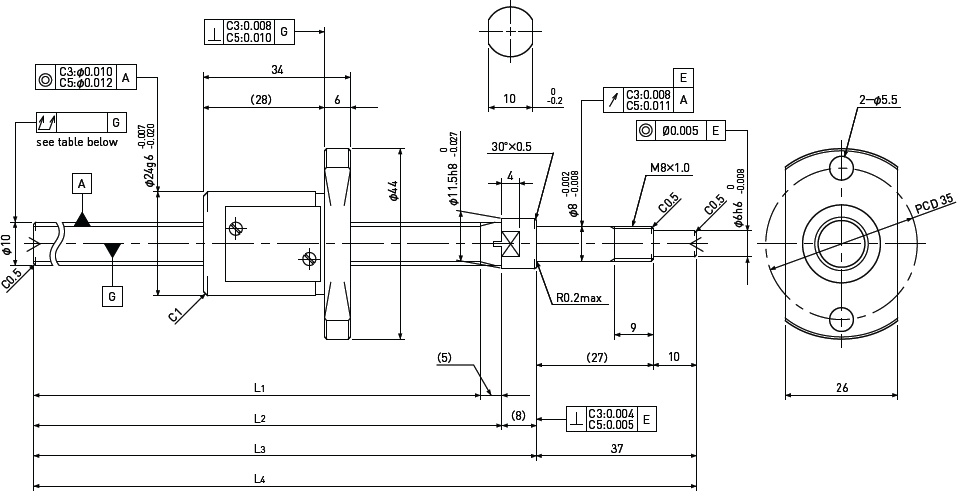

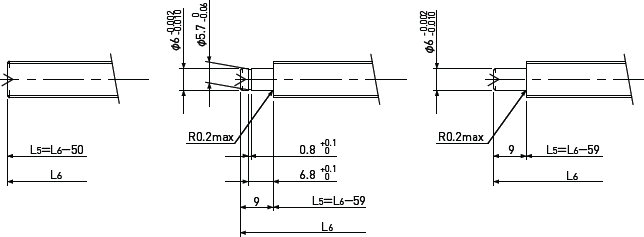

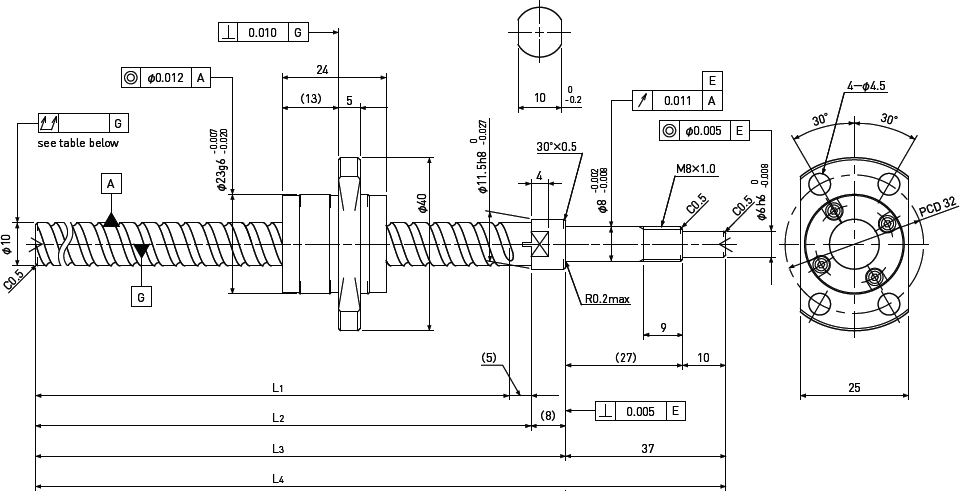

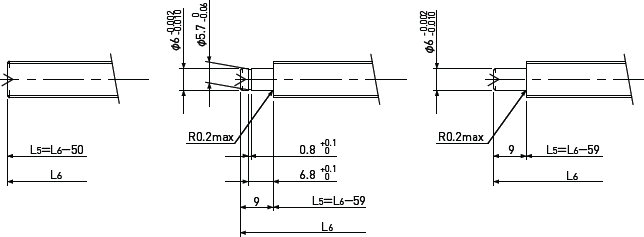

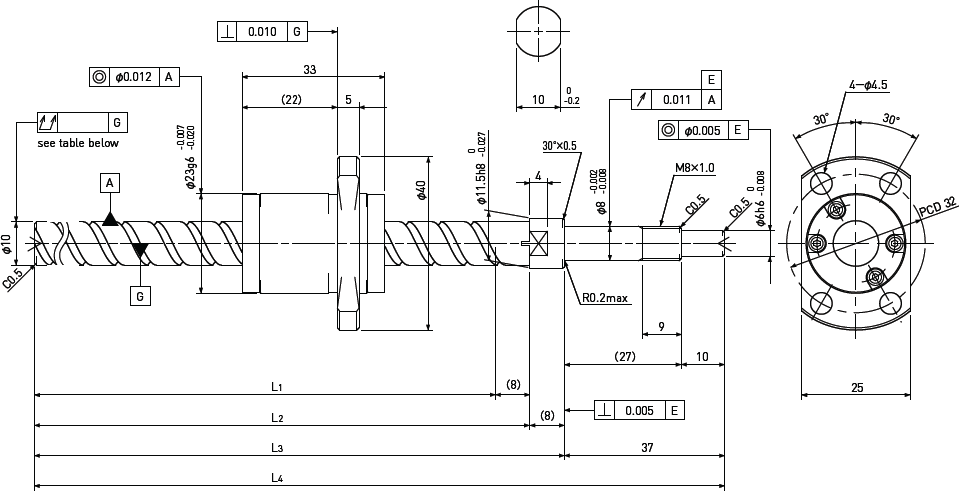

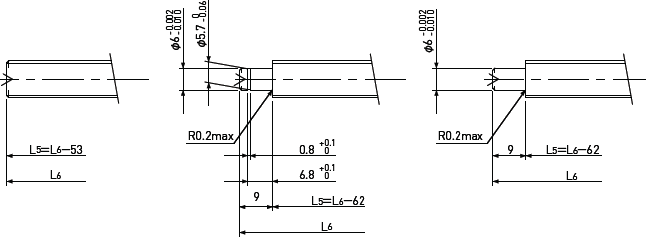

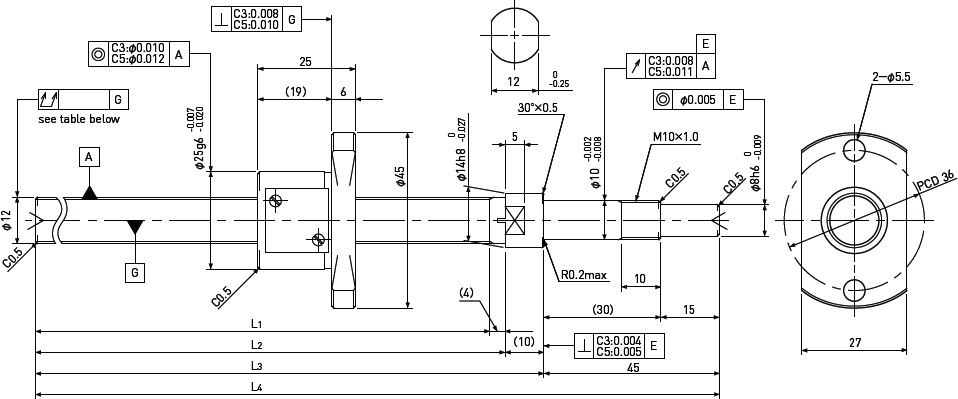

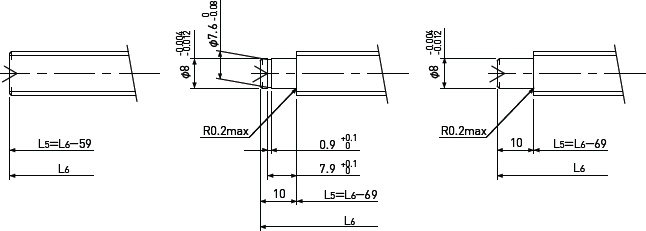

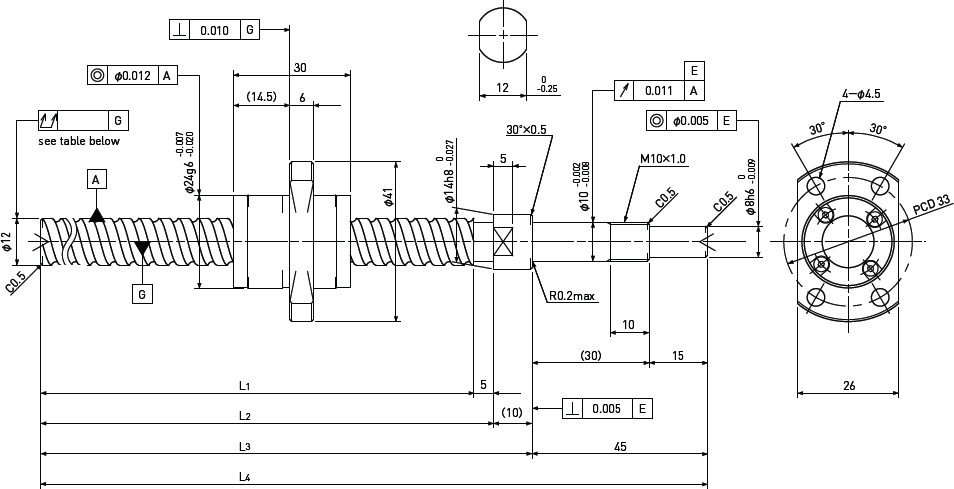

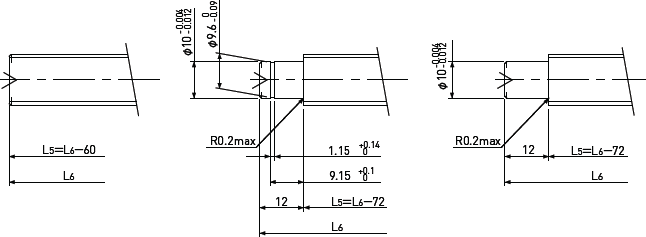

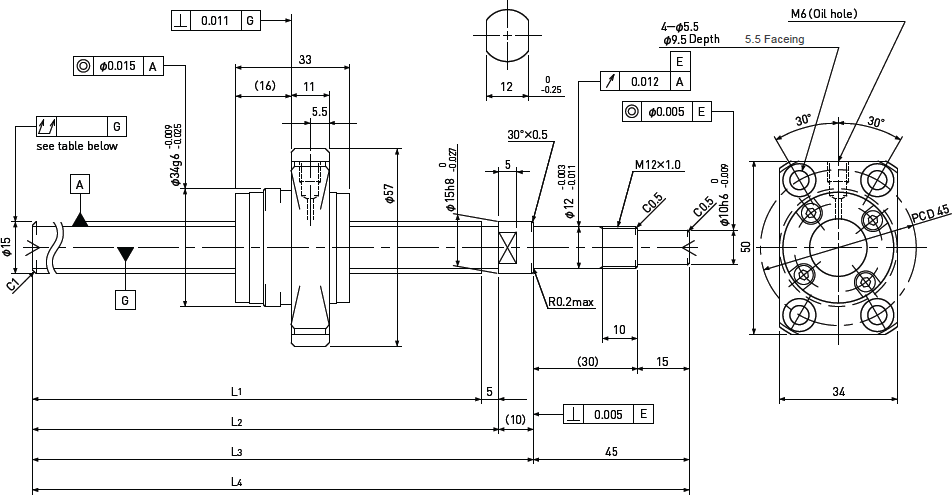

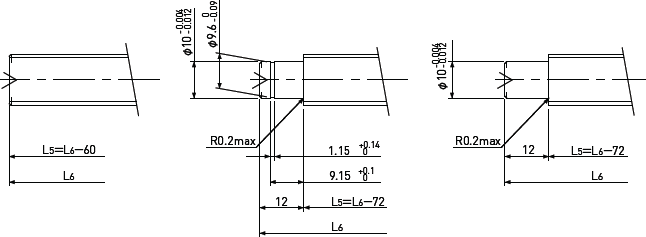

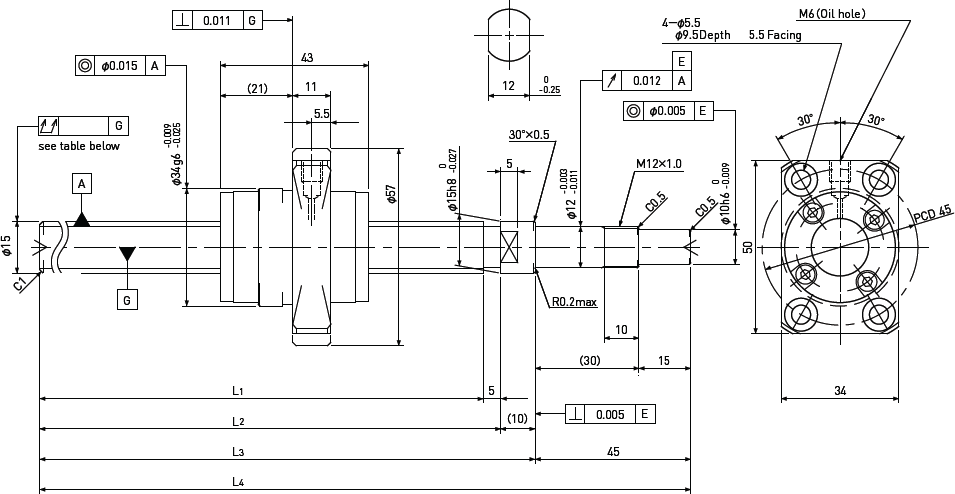

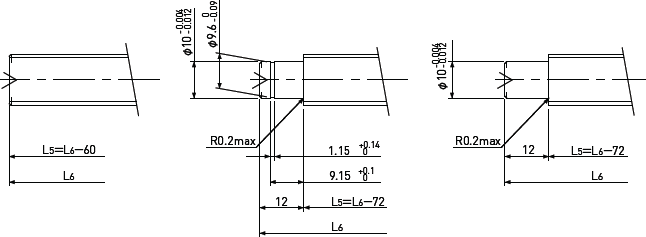

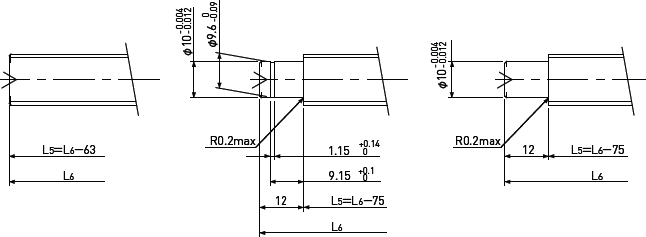

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | - |

| Fixed-side: | EK4 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0300.5-038R070C3 | 25 | C3 | 38 | 41 | 47 | 70 | ±0.008 | 0.008 | 0.025 | ~0.005 | - | 150 | 220 |

| Standard products in stock SG series | |||

|---|---|---|---|

SG0301 | Shaft dia. ∅3 | Lead 1mm | C3 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅0.6 | A-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅2.4 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | - |

| Fixed-side: | EK4 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0301-038R070C3 | 20 | C3 | 38 | 41 | 47 | 70 | ±0.008 | 0.008 | 0.025 | ~0.005 | - | 330 | 440 |

| Standard products in stock SG series | |||

|---|---|---|---|

SG0401 | Shaft dia. ∅4 | Lead 1mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

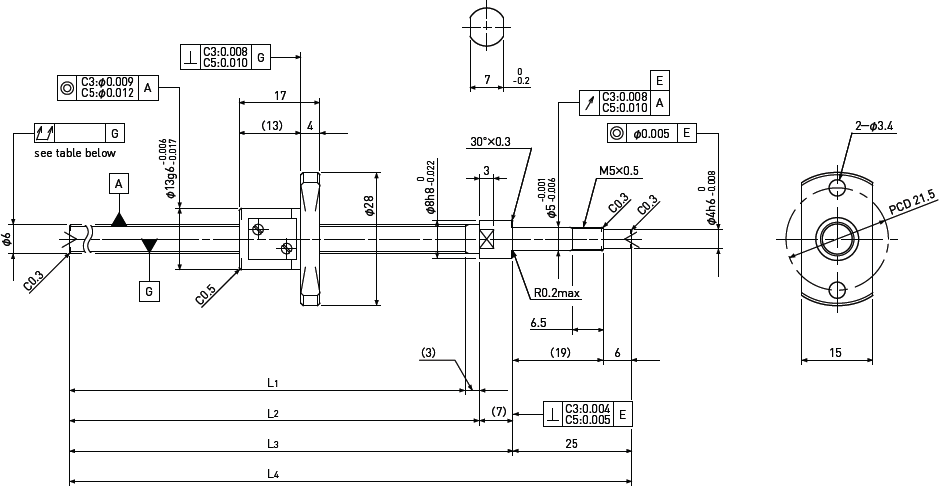

| Ball Screw Specifications | Supported-side end-journal profile | |||

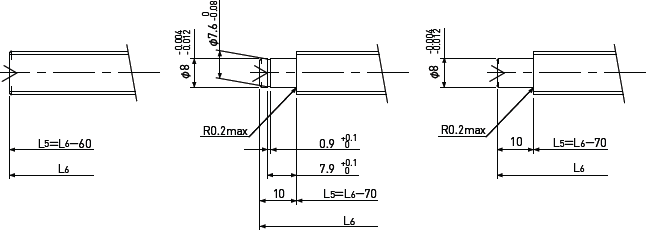

| Ball size | ∅0.8 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅3.3 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

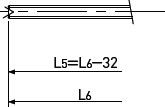

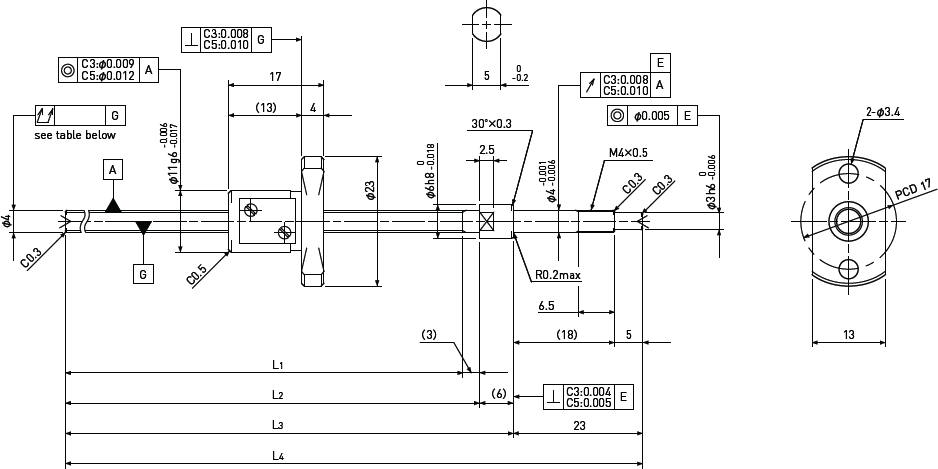

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP03-S |

| Fixed-side: | EK4 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0401-063R095C3 | 45 | C3 | 63 | 66 | 72 | 95 | ±0.008 | 0.008 | 0.025 | 0 Spacer Ball (1:1) | ~0.004 | 350 | 400 |

| SG0401-083R115C3 | 65 | C3 | 83 | 86 | 92 | 115 | ±0.008 | 0.008 | 0.025 | ||||

| SG0401-103R135C3 | 85 | C3 | 103 | 106 | 112 | 135 | ±0.010 | 0.008 | 0.035 | ||||

| SG0401-063R095C5 | 45 | C5 | 63 | 66 | 72 | 95 | ±0.018 | 0.018 | 0.035 | ~0.005 | - | 560 | 790 |

| SG0401-083R115C5 | 65 | C5 | 83 | 86 | 92 | 115 | ±0.018 | 0.018 | 0.035 | ||||

| SG0401-103R135C5 | 85 | C5 | 103 | 106 | 112 | 135 | ±0.020 | 0.018 | 0.050 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0402 | Shaft dia. ∅4 | Lead 2mm | C3 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅0.8 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅3.3 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP03-S |

| Fixed-side: | EK4 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0402-103R135C3 | 80 | C3 | 103 | 106 | 112 | 135 | ±0.010 | 0.008 | 0.035 | ~0.005 | - | 420 | 570 |

| Standard products in stock SG series | |||

|---|---|---|---|

SG0504 | Shaft dia. ∅5 | Lead 4mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅0.8 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅4.3 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP03-S |

| Fixed-side: | EK4 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0504-062R095C3 | 40 | C3 | 62 | 66 | 72 | 95 | ±0.008 | 0.008 | 0.025 | 0 Spacer Ball (1:1) | ~0.005 | 300 | 360 |

| SG0504-112R145C3 | 90 | C3 | 112 | 116 | 122 | 145 | ±0.010 | 0.008 | 0.035 | ||||

| SG0504-062R095C5 | 40 | C5 | 62 | 66 | 72 | 95 | ±0.018 | 0.018 | 0.035 | ~0.005 | - | 470 | 720 |

| SG0504-112R145C5 | 90 | C5 | 112 | 116 | 122 | 145 | ±0.020 | 0.018 | 0.050 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0601 | Shaft dia. ∅6 | Lead 1mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

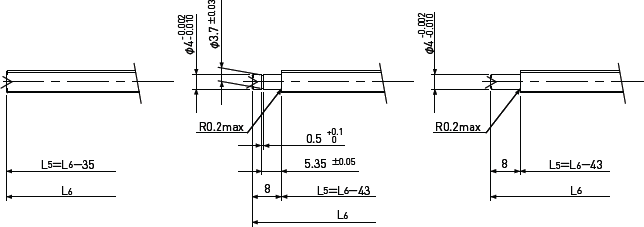

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅0.8 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅5.3 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP04-S |

| Fixed-side: | EK5 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0601-085R120C3 | 65 | C3 | 85 | 88 | 95 | 120 | ±0.008 | 0.008 | 0.025 | 0 Spacer Ball (1:1) | ~0.006 | 430 | 610 |

| SG0601-110R145C3 | 90 | C3 | 110 | 113 | 120 | 145 | ±0.010 | 0.008 | 0.035 | ||||

| SG0601-135R170C3 | 115 | C3 | 135 | 138 | 145 | 170 | ±0.010 | 0.008 | 0.035 | ||||

| SG0601-085R120C5 | 65 | C5 | 85 | 88 | 95 | 120 | ±0.018 | 0.018 | 0.035 | ~0.005 | - | 680 | 1200 |

| SG0601-110R145C5 | 90 | C5 | 110 | 113 | 120 | 145 | ±0.020 | 0.018 | 0.050 | ||||

| SG0601-135R170C5 | 115 | C5 | 135 | 138 | 145 | 170 | ±0.020 | 0.018 | 0.050 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0602 | Shaft dia. ∅6 | Lead 2mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.0 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅5.1 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP04-S |

| Fixed-side: | EK5 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0602-085R120C3 | 65 | C3 | 85 | 88 | 95 | 120 | ±0.008 | 0.008 | 0.025 | 0 Spacer Ball (1:1) | 0.003~0.007 | 470 | 590 |

| SG0602-135R170C3 | 115 | C3 | 135 | 138 | 145 | 170 | ±0.010 | 0.008 | 0.035 | ||||

| SG0602-085R120C5 | 65 | C5 | 85 | 88 | 95 | 120 | ±0.018 | 0.018 | 0.035 | ~0.005 | - | 750 | 1200 |

| SG0602-135R170C5 | 115 | C5 | 135 | 138 | 145 | 170 | ±0.020 | 0.018 | 0.050 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0602.5 | Shaft dia. ∅6 | Lead 2.5mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.0 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅5.1 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP04-S |

| Fixed-side: | EK5 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0602.5-085R120C3 | 65 | C3 | 85 | 88 | 95 | 120 | ±0.008 | 0.008 | 0.025 | 0 Spacer Ball (1:1) | 0.003~0.007 | 470 | 590 |

| SG0602.5-135R170C3 | 115 | C3 | 135 | 138 | 145 | 170 | ±0.010 | 0.008 | 0.035 | ||||

| SG0602.5-085R120C5 | 65 | C5 | 85 | 88 | 95 | 120 | ±0.018 | 0.018 | 0.035 | ~0.005 | - | 750 | 1200 |

| SG0602.5-135R170C5 | 115 | C5 | 135 | 138 | 145 | 170 | ±0.020 | 0.018 | 0.050 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0606 | Shaft dia. ∅6 | Lead 6mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.0 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅5.2 | |||

| Number of circuit | 1.6×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP04-S |

| Fixed-side: | EK5 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0606-084R120C5 | 65 | C5 | 84 | 88 | 95 | 120 | ±0.018 | 0.018 | 0.035 | ~0.005 | - | 870 | 1450 |

| SG0606-134R170C5 | 115 | C5 | 134 | 138 | 145 | 170 | ±0.020 | 0.018 | 0.050 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0610 | Shaft dia. ∅6 | Lead 10mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.2 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅5.0 | |||

| Number of circuit | 1.2×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | SUP04-S |

| Fixed-side: | EK5 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0610-133R170C5 | 110 | C5 | 133 | 138 | 145 | 170 | ±0.020 | 0.018 | 0.050 | ~0.005 | - | 950 | 1600 |

| Standard products in stock SG series | |||

|---|---|---|---|

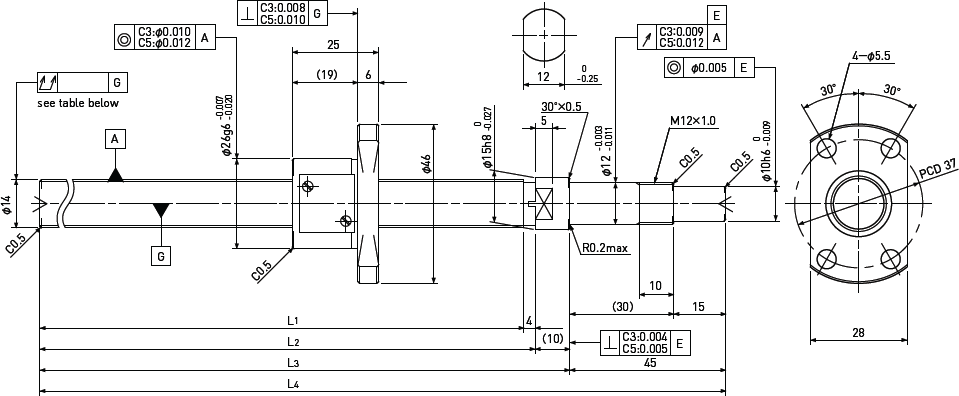

SG0801 | Shaft dia. ∅8 | Lead 1mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

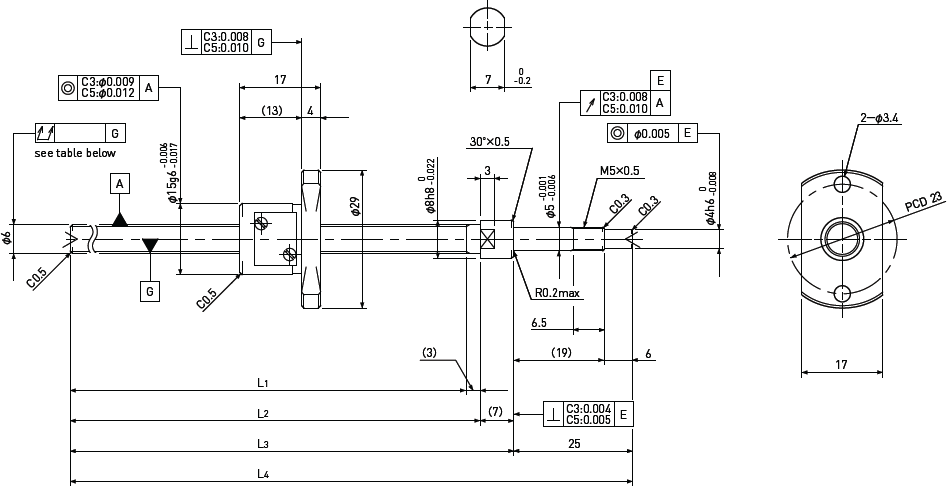

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅0.8 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅7.3 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF6 |

| Fixed-side: | EK6 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0801-100R140C3 | 80 | C3 | 100 | 103 | 110 | 140 | ±0.008 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | 0.002~0.008 | 490 | 820 |

| SG0801-130R170C3 | 110 | C3 | 130 | 133 | 140 | 170 | ±0.010 | 0.008 | 0.035 | ||||

| SG0801-160R200C3 | 140 | C3 | 160 | 163 | 170 | 200 | ±0.010 | 0.008 | 0.035 | ||||

| SG0801-210R250C3 | 190 | C3 | 210 | 213 | 220 | 250 | ±0.012 | 0.008 | 0.050 | ||||

| SG0801-100R140C5 | 80 | C5 | 100 | 103 | 110 | 140 | ±0.018 | 0.018 | 0.050 | ~0.005 | - | 780 | 1650 |

| SG0801-130R170C5 | 110 | C5 | 130 | 133 | 140 | 170 | ±0.020 | 0.018 | 0.050 | ||||

| SG0801-160R200C5 | 140 | C5 | 160 | 163 | 170 | 200 | ±0.020 | 0.018 | 0.050 | ||||

| SG0801-210R250C5 | 190 | C5 | 210 | 213 | 220 | 250 | ±0.023 | 0.018 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0802 | Shaft dia. ∅8 | Lead 2mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅6.6 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF6 |

| Fixed-side: | EK6 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0802-099R140C3 | 75 | C3 | 99 | 103 | 110 | 140 | ±0.008 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | 0.004~0.020 | 1550 | 2100 |

| SG0802-129R170C3 | 105 | C3 | 129 | 133 | 140 | 170 | ±0.010 | 0.008 | 0.035 | ||||

| SG0802-159R200C3 | 135 | C3 | 159 | 163 | 170 | 200 | ±0.010 | 0.008 | 0.035 | ||||

| SG0802-209R250C3 | 185 | C3 | 209 | 213 | 220 | 250 | ±0.012 | 0.008 | 0.050 | ||||

| SG0802-099R140C5 | 75 | C5 | 99 | 103 | 110 | 140 | ±0.018 | 0.018 | 0.050 | ~0.005 | - | 2400 | 4100 |

| SG0802-129R170C5 | 105 | C5 | 129 | 133 | 140 | 170 | ±0.020 | 0.018 | 0.050 | ||||

| SG0802-159R200C5 | 135 | C5 | 159 | 163 | 170 | 200 | ±0.020 | 0.018 | 0.050 | ||||

| SG0802-209R250C5 | 185 | C5 | 209 | 213 | 220 | 250 | ±0.023 | 0.018 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0802.5 | Shaft dia. ∅8 | Lead 2.5mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅6.3 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF6 |

| Fixed-side: | EK6 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0802.5-129R170C5 | 110 | C5 | 129 | 133 | 140 | 170 | ±0.020 | 0.018 | 0.050 | ~0.005 | - | 1850 | 3000 |

| SG0802.5-209R250C5 | 190 | C5 | 209 | 213 | 220 | 250 | ±0.023 | 0.018 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0804 | Shaft dia. ∅8 | Lead 4mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅2.0 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅6.2 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF6 |

| Fixed-side: | EK6 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0804-098R140C3 | 70 | C3 | 98 | 103 | 110 | 140 | ±0.008 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | ~0.015 | 1650 | 2100 |

| SG0804-208R250C3 | 180 | C3 | 208 | 213 | 220 | 250 | ±0.012 | 0.008 | 0.050 | ||||

| SG0804-098R140C5 | 70 | C5 | 98 | 103 | 110 | 140 | ±0.018 | 0.018 | 0.050 | ~0.005 | - | 2600 | 4200 |

| SG0804-208R250C5 | 180 | C5 | 208 | 213 | 220 | 250 | ±0.023 | 0.018 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0805 | Shaft dia. ∅8 | Lead 5mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅6.6 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF6 |

| Fixed-side: | EK6 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0805-099R140C3 | 70 | C3 | 99 | 103 | 110 | 140 | ±0.008 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | ~0.015 | 1150 | 1500 |

| SG0805-209R250C3 | 180 | C3 | 209 | 213 | 220 | 250 | ±0.012 | 0.008 | 0.050 | ||||

| SG0805-099R140C5 | 70 | C5 | 99 | 103 | 110 | 140 | ±0.018 | 0.018 | 0.050 | ~0.005 | - | 1850 | 3000 |

| SG0805-209R250C5 | 180 | C5 | 209 | 213 | 220 | 250 | ±0.023 | 0.018 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0808 | Shaft dia. ∅8 | Lead 8mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅6.7 | |||

| Number of circuit | 1.6×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF6 |

| Fixed-side: | EK6 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0808-099R140C5 | 75 | C5 | 99 | 103 | 110 | 140 | ±0.018 | 0.018 | 0.050 | ~0.005 | - | 2200 | 3800 |

| SG0808-209R250C5 | 185 | C5 | 209 | 213 | 220 | 250 | ±0.023 | 0.018 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG0812 | Shaft dia. ∅8 | Lead 12mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅6.7 | |||

| Number of circuit | 1.6×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF6 |

| Fixed-side: | EK6 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG0812-097R140C5 | 70 | C5 | 97 | 103 | 110 | 140 | ±0.018 | 0.018 | 0.050 | ~0.005 | - | 2200 | 4000 |

| SG0812-207R250C5 | 180 | C5 | 207 | 213 | 220 | 250 | ±0.023 | 0.018 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

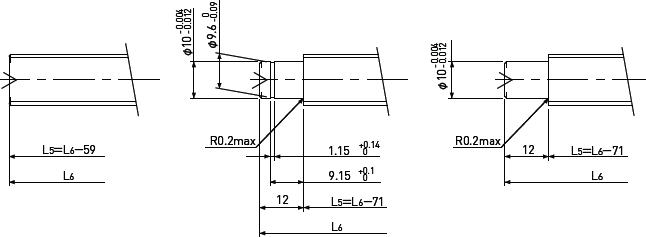

SG1001 | Shaft dia. ∅10 | Lead 1mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅0.8 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅9.3 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF8 |

| Fixed-side: | EK8 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1001-112R160C3 | 90 | C3 | 112 | 115 | 123 | 160 | ±0.010 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | ~0.020 | 530 | 1000 |

| SG1001-162R210C3 | 140 | C3 | 162 | 165 | 173 | 210 | ±0.010 | 0.008 | 0.040 | ||||

| SG1001-212R260C3 | 190 | C3 | 212 | 215 | 223 | 260 | ±0.012 | 0.008 | 0.040 | ||||

| SG1001-262R310C3 | 240 | C3 | 262 | 265 | 273 | 310 | ±0.012 | 0.008 | 0.040 | ||||

| SG1001-112R160C5 | 90 | C5 | 112 | 115 | 123 | 160 | ±0.020 | 0.018 | 0.040 | ~0.005 | - | 840 | 2000 |

| SG1001-162R210C5 | 140 | C5 | 162 | 165 | 173 | 210 | ±0.020 | 0.018 | 0.055 | ||||

| SG1001-212R260C5 | 190 | C5 | 212 | 215 | 223 | 260 | ±0.023 | 0.018 | 0.055 | ||||

| SG1001-262R310C5 | 240 | C5 | 262 | 265 | 273 | 310 | ±0.023 | 0.018 | 0.055 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1002 | Shaft dia. ∅10 | Lead 2mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅8.6 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF8 |

| Fixed-side: | EK8 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1002-111R160C3 | C3 | 111 | 115 | 123 | 160 | ±0.010 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | 0.006~0.030 | 1750 | 2700 | |

| SG1002-161R210C3 | C3 | 161 | 165 | 173 | 210 | ±0.010 | 0.008 | 0.040 | |||||

| SG1002-211R260C3 | C3 | 211 | 215 | 223 | 260 | ±0.012 | 0.008 | 0.040 | |||||

| SG1002-261R310C3 | C3 | 261 | 265 | 273 | 310 | ±0.012 | 0.008 | 0.040 | |||||

| SG1002-111R160C5 | C5 | 111 | 115 | 123 | 160 | ±0.020 | 0.018 | 0.040 | ~0.005 | - | 2700 | 5300 | |

| SG1002-161R210C5 | C5 | 161 | 165 | 173 | 210 | ±0.020 | 0.018 | 0.055 | |||||

| SG1002-211R260C5 | C5 | 211 | 215 | 223 | 260 | ±0.023 | 0.018 | 0.055 | |||||

| SG1002-261R310C5 | C5 | 261 | 265 | 273 | 310 | ±0.023 | 0.018 | 0.055 | |||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1004 | Shaft dia. ∅10 | Lead 4mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅2.0 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅8.2 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF8 |

| Fixed-side: | EK8 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1004-110R160C3 | 80 | C3 | 110 | 115 | 123 | 160 | ±0.010 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | 0.005~0.040 | 1800 | 2600 |

| SG1004-260R310C3 | 230 | C3 | 260 | 265 | 273 | 310 | ±0.012 | 0.008 | 0.040 | ||||

| SG1004-110R160C5 | 80 | C5 | 110 | 115 | 123 | 160 | ±0.020 | 0.018 | 0.040 | ~0.005 | - | 3000 | 5200 |

| SG1004-260R310C5 | 230 | C5 | 260 | 265 | 273 | 310 | ±0.023 | 0.018 | 0.055 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1005 | Shaft dia. ∅10 | Lead 5mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅2.0 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅8.2 | |||

| Number of circuit | 2.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF8 |

| Fixed-side: | EK8 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1005-110R160C3 | 75 | C3 | 110 | 115 | 123 | 160 | ±0.010 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | 0.005~0.040 | 1800 | 2600 |

| SG1005-260R310C3 | 225 | C3 | 260 | 265 | 273 | 310 | ±0.012 | 0.008 | 0.040 | ||||

| SG1005-110R160C5 | 75 | C5 | 110 | 115 | 123 | 160 | ±0.020 | 0.018 | 0.040 | ~0.005 | - | 3000 | 5200 |

| SG1005-260R310C5 | 225 | C5 | 260 | 265 | 273 | 310 | ±0.023 | 0.018 | 0.055 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1010 | Shaft dia. ∅10 | Lead 10mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅2.0 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅8.4 | |||

| Number of circuit | 1.6×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF8 |

| Fixed-side: | EK8 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1010-110R160C5 | 85 | C5 | 110 | 115 | 123 | 160 | ±0.020 | 0.018 | 0.040 | ~0.005 | - | 3300 | 5900 |

| SG1010-260R310C5 | 235 | C5 | 260 | 265 | 273 | 310 | ±0.023 | 0.018 | 0.055 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1015 | Shaft dia. ∅10 | Lead 15mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅2.0 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅8.4 | |||

| Number of circuit | 1.6×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF8 |

| Fixed-side: | EK8 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1015-107R160C5 | 70 | C5 | 107 | 115 | 123 | 160 | ±0.020 | 0.018 | 0.040 | ~0.005 | - | 3300 | 6400 |

| SG1015-257R310C5 | 220 | C5 | 257 | 265 | 273 | 310 | ±0.023 | 0.018 | 0.055 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

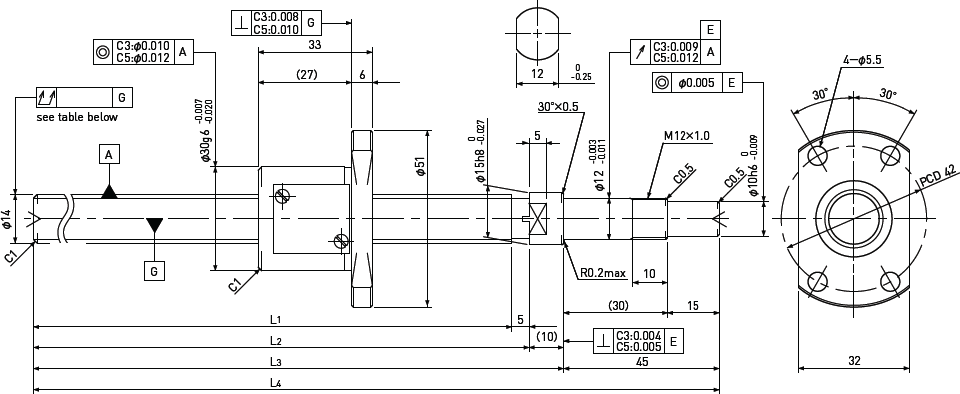

SG1202 | Shaft dia. ∅12 | Lead 2mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

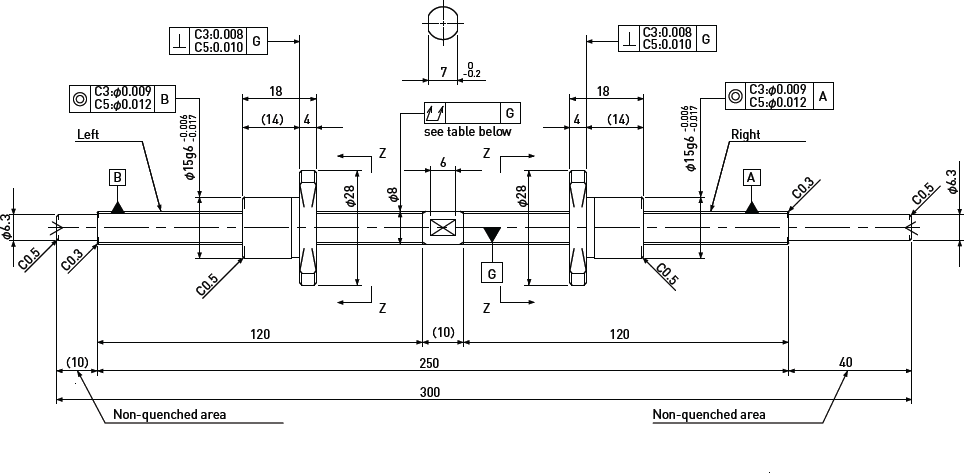

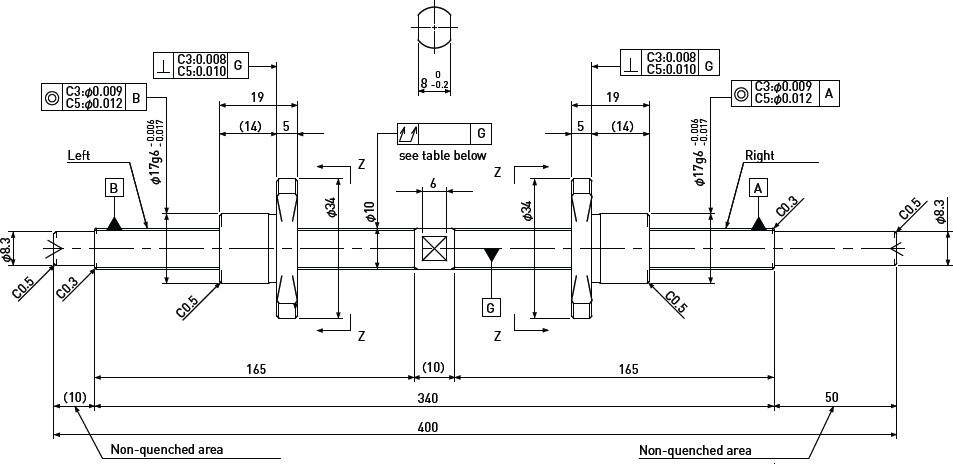

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅10.6 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF10 |

| Fixed-side: | EK10 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1202-141R200C3 | 115 | C3 | 141 | 145 | 155 | 200 | ±0.008 | 0.008 | 0.035 | 0 Spacer Ball (1:1) | 0.008~0.040 | 1900 | 3200 |

| SG1202-191R250C3 | 165 | C3 | 191 | 195 | 205 | 250 | ±0.008 | 0.008 | 0.040 | ||||

| SG1202-241R300C3 | 215 | C3 | 241 | 245 | 255 | 300 | ±0.008 | 0.008 | 0.040 | ||||

| SG1202-291R350C3 | 265 | C3 | 291 | 295 | 305 | 350 | ±0.008 | 0.008 | 0.050 | ||||

| SG1202-341R400C3 | 315 | C3 | 341 | 345 | 355 | 400 | ±0.010 | 0.010 | 0.050 | ||||

| SG1202-141R200C5 | 115 | C5 | 141 | 145 | 155 | 200 | ±0.008 | 0.018 | 0.040 | ~0.005 | - | 3000 | 6400 |

| SG1202-191R250C5 | 165 | C5 | 191 | 195 | 205 | 250 | ±0.008 | 0.018 | 0.055 | ||||

| SG1202-241R300C5 | 215 | C5 | 241 | 245 | 255 | 300 | ±0.008 | 0.018 | 0.055 | ||||

| SG1202-291R350C5 | 265 | C5 | 291 | 295 | 305 | 350 | ±0.008 | 0.018 | 0.065 | ||||

| SG1202-341R400C5 | 315 | C5 | 341 | 245 | 355 | 400 | ±0.010 | 0.020 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1210 | Shaft dia. ∅12 | Lead 10mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅2.381 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅10.2 | |||

| Number of circuit | 1.7×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF10 |

| Fixed-side: | EK10 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1210-240R300C5 | 210 | C5 | 240 | 245 | 255 | 300 | ±0.023 | 0.018 | 0.055 | ~0.005 | - | 5100 | 9800 |

| SG1210-340R400C5 | 310 | C5 | 340 | 345 | 355 | 400 | ±0.025 | 0.020 | 0.065 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1402 | Shaft dia. ∅14 | Lead 2mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅1.5875 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅12.6 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF12 |

| Fixed-side: | EK12 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1402-141R200C3 | 115 | C3 | 141 | 145 | 155 | 200 | ±0.010 | 0.008 | 0.025 | 0 Spacer Ball (1:1) | 0.010~0.050 | 2000 | 3800 |

| SG1402-191R250C3 | 165 | C3 | 191 | 195 | 205 | 250 | ±0.010 | 0.008 | 0.030 | ||||

| SG1402-241R300C3 | 215 | C3 | 241 | 245 | 255 | 300 | ±0.012 | 0.008 | 0.030 | ||||

| SG1402-291R350C3 | 265 | C3 | 291 | 295 | 305 | 350 | ±0.012 | 0.008 | 0.040 | ||||

| SG1402-391R450C3 | 365 | C3 | 391 | 395 | 405 | 450 | ±0.013 | 0.010 | 0.050 | ||||

| SG1402-141R200C5 | 115 | C5 | 141 | 145 | 155 | 200 | ±0.020 | 0.018 | 0.040 | ~0.005 | - | 3200 | 7500 |

| SG1402-191R250C5 | 165 | C5 | 191 | 195 | 205 | 250 | ±0.020 | 0.018 | 0.045 | ||||

| SG1402-241R300C5 | 215 | C5 | 241 | 245 | 255 | 300 | ±0.023 | 0.018 | 0.045 | ||||

| SG1402-291R350C5 | 265 | C5 | 291 | 295 | 305 | 350 | ±0.023 | 0.018 | 0.055 | ||||

| SG1402-391R450C5 | 365 | C5 | 391 | 395 | 405 | 450 | ±0.025 | 0.020 | 0.060 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1404 | Shaft dia. ∅14 | Lead 4mm | C3&C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅2.381 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅11.8 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF12 |

| Fixed-side: | EK12 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1404-190R250C3 | 155 | C3 | 190 | 195 | 205 | 250 | ±0.010 | 0.008 | 0.030 | 0 Spacer Ball (1:1) | 0.020~0.070 | 3600 | 5800 |

| SG1404-240R300C3 | 205 | C3 | 240 | 245 | 255 | 300 | ±0.012 | 0.008 | 0.030 | ||||

| SG1404-290R350C3 | 255 | C3 | 290 | 295 | 305 | 350 | ±0.012 | 0.008 | 0.040 | ||||

| SG1404-390R450C3 | 355 | C3 | 390 | 395 | 405 | 450 | ±0.013 | 0.010 | 0.050 | ||||

| SG1404-490R550C3 | 455 | C3 | 490 | 495 | 505 | 550 | ±0.015 | 0.010 | 0.055 | ||||

| SG1404-190R250C5 | 155 | C5 | 190 | 195 | 205 | 250 | ±0.020 | 0.018 | 0.045 | ~0.005 | - | 5700 | 11600 |

| SG1404-240R300C5 | 205 | C5 | 240 | 245 | 255 | 300 | ±0.023 | 0.018 | 0.045 | ||||

| SG1404-290R350C5 | 255 | C5 | 290 | 295 | 305 | 350 | ±0.023 | 0.018 | 0.055 | ||||

| SG1404-390R450C5 | 355 | C5 | 390 | 395 | 405 | 450 | ±0.025 | 0.020 | 0.060 | ||||

| SG1404-490R550C5 | 455 | C5 | 490 | 495 | 505 | 550 | ±0.027 | 0.020 | 0.075 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1505 | Shaft dia. ∅15 | Lead 5mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅3.175 | A-type B-type C-type | ||

| Number of thread | 1 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅12.2 | |||

| Number of circuit | 3.7×1 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF12 |

| Fixed-side: | EK12 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1505-340R400C5 | 305 | C5 | 340 | 345 | 355 | 400 | ±0.025 | 0.020 | 0.055 | ~0.005 | - | 8900 | 17000 |

| SG1505-540R600C5 | 505 | C5 | 540 | 545 | 555 | 600 | ±0.030 | 0.023 | 0.075 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1510 | Shaft dia. ∅15 | Lead 10mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅3.175 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅12.2 | |||

| Number of circuit | 2.7×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF12 |

| Fixed-side: | EK12 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1510-340R400C5 | 295 | C5 | 340 | 345 | 355 | 400 | ±0.025 | 0.020 | 0.055 | ~0.005 | - | 12000 | 25000 |

| SG1510-540R600C5 | 495 | C5 | 540 | 545 | 555 | 600 | ±0.030 | 0.023 | 0.075 | ||||

| Standard products in stock SG series | |||

|---|---|---|---|

SG1520 | Shaft dia. ∅15 | Lead 20mm | C5 |

| Unit : mm | ||||

|---|---|---|---|---|

| Ball Screw Specifications | Supported-side end-journal profile | |||

| Ball size | ∅3.175 | A-type B-type C-type | ||

| Number of thread | 2 | |||

| Thread direction | Right | |||

| Shaft root dia. | ∅12.4 | |||

| Number of circuit | 1.7×2 | |||

| Shaft/Nut Material | SCM415H | |||

| Surface hardness | HRC58∼62 (Thread area) | L5: Thread length after end-journal machining. L6: Total length after end-journal machining. | ||

| Anti-rust treatment | Anti-rust oil | Support-unit Recommendation | Supported-side: | EF12 |

| Fixed-side: | EK12 | |||

| Unit : mm | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ball Screw Model | Travel | Grade | Shaft length | Lead accuracy | Total Run-out ⌰ | Axial play | Preload Torque Nm | Basic Load Rating N | |||||

| L1 | L2 | L3 | L4 | Travel deviation eP | Variation Vu | Dynamic Ca | Static Coa | ||||||

| SG1520-337R400C5 | 285 | C5 | 337 | 345 | 355 | 400 | ±0.025 | 0.020 | 0.055 | ~0.005 | - | 8000 | 16000 |

| SG1520-537R600C5 | 485 | C5 | 537 | 545 | 555 | 600 | ±0.030 | 0.023 | 0.075 | ||||

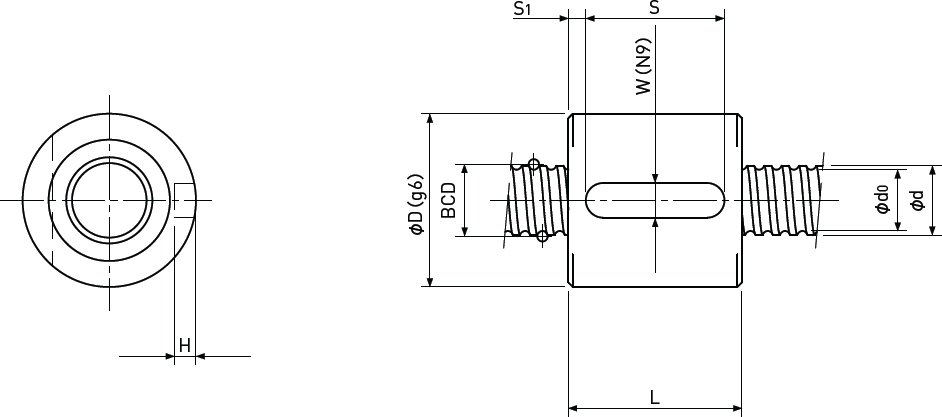

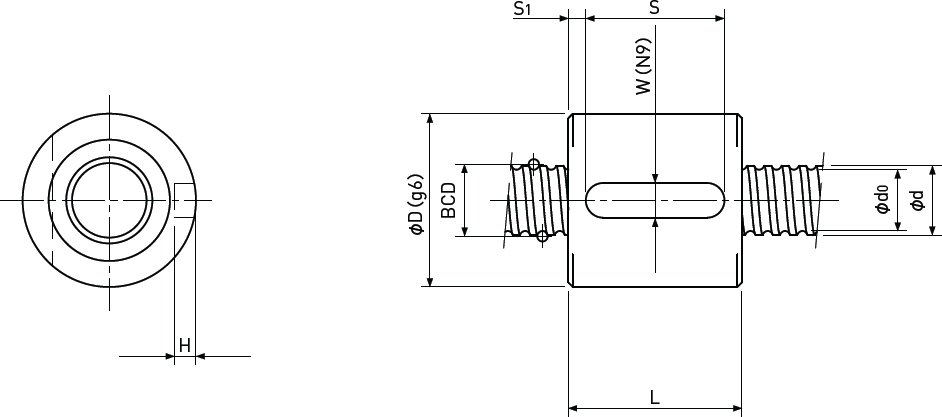

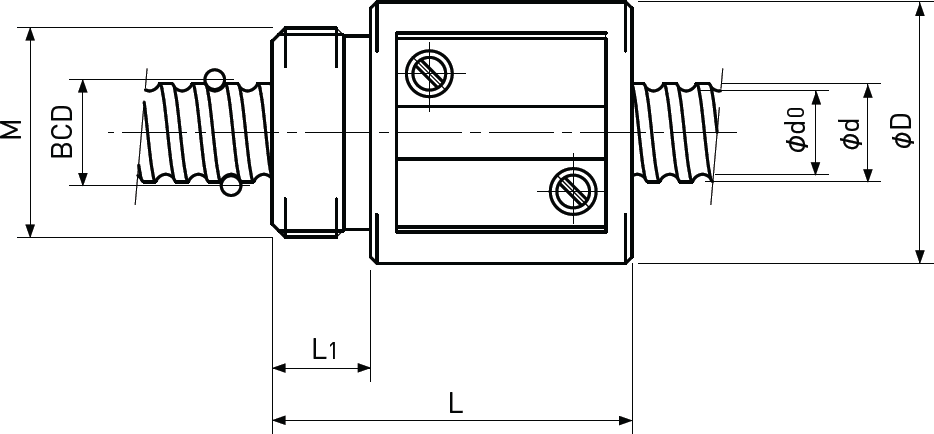

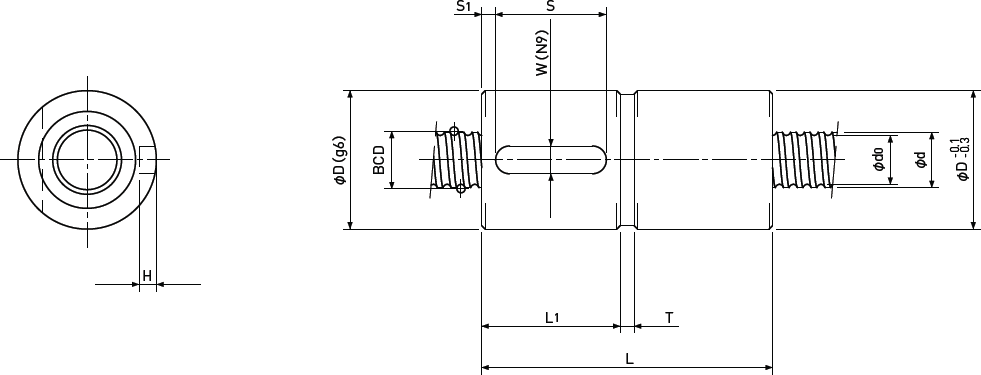

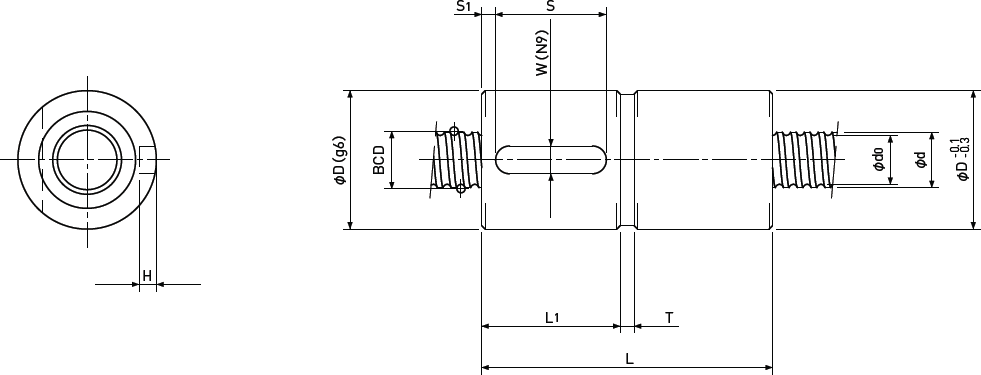

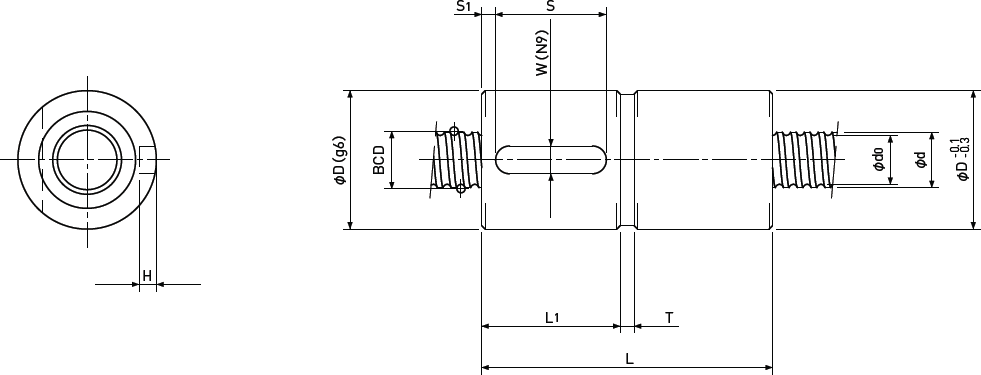

| Precision Ball Screws | |

|---|---|

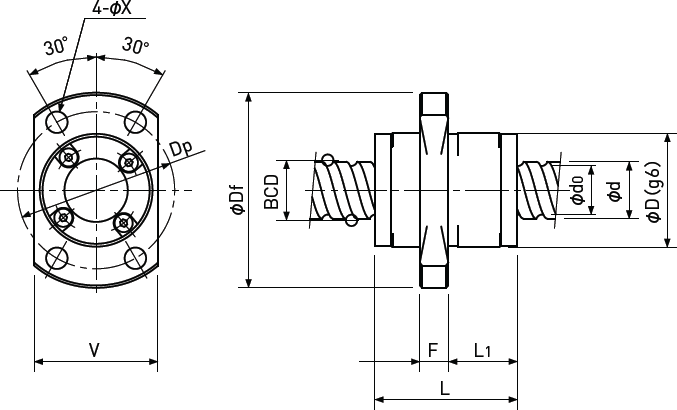

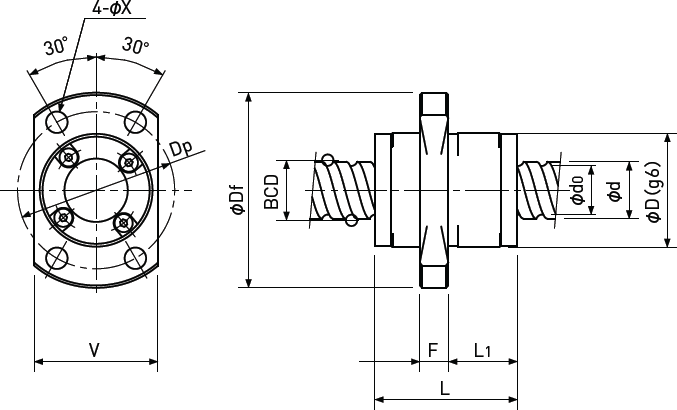

Sleeve type Single Nut | Backlash type/Preload type |

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| BS 0301 B | 3 | 1 | 0.6 | 3.18 | 5°43' | 2.4 | 3.7×1 | 330 / - | 440 / - | 42 / - |

| BS 0401 A | 4 | 1 | 0.8 | 4.15 | 4°23' | 3.3 | 2.7×1 | 420 / 270 | 570 / 290 | 40 / 34 |

| BS 0401 B | 4 | 1 | 0.8 | 4.15 | 4°23' | 3.3 | 3.7×1 | 560 / 350 | 790 / 400 | 54 / 45 |

| BS 0402 A | 4 | 2 | 0.8 | 4.15 | 8°43' | 3.3 | 2.7×1 | 420 / 260 | 570 / 290 | 39 / 33 |

| BS 0403 A | 4 | 3 | 0.8 | 4.15 | 12°57' | 3.3 | 2.7×1 | 420 / - | 570 / - | 39 / - |

| BS 0501 B | 5 | 1 | 0.8 | 5.15 | 3°32' | 4.3 | 3.7×1 | 630 / 400 | 1000 / 500 | 65 / 55 |

| BS 0504 A | 5 | 4 | 0.8 | 5.15 | 13°53' | 4.3 | 2.7×1 | 470 / 300 | 720 / 360 | 47 / 39 |

| BS 0601 B | 6 | 1 | 0.8 | 6.15 | 2°58' | 5.3 | 3.7×1 | 680 / 430 | 1200 / 610 | 75 / 63 |

| BS 0601.5 B | 6 | 1.5 | 1 | 6.2 | 4°24' | 5.1 | 3.7×1 | 980 / 620 | 1600 / 800 | 79 / 67 |

| BS 0602 A | 6 | 2 | 1 | 6.2 | 5°52' | 5.1 | 2.7×1 | 750 / 470 | 1200 / 590 | 58 / 49 |

| BS 0602 B | 6 | 2 | 1 | 6.2 | 5°52' | 5.1 | 3.7×1 | 980 / 620 | 1600 / 800 | 79 / 67 |

| BS 0602.5 A | 6 | 2.5 | 1 | 6.2 | 7°19' | 5.1 | 2.7×1 | 750 / 470 | 1200 / 590 | 59 / 49 |

| Ball Nut Model number | Nut dimension | |||||

|---|---|---|---|---|---|---|

| D | L | W | H | S | S1 | |

| BS 0301 B | 9 | 12 | 2 | 1.2 | 8 | 2 |

| BS 0401 A | 10 | 12 | 2 | 1.2 | 8 | 2 |

| BS 0401 B | 11 | 14 | 3 | 1.8 | 8 | 3 |

| BS 0402 A | 11 | 16 | 3 | 1.8 | 8 | 4 |

| BS 0403 A | 11 | 20 | 3 | 1.8 | 8 | 6 |

| BS 0501 B | 12 | 14 | 3 | 1.8 | 8 | 3 |

| BS 0504 A | 12 | 22 | 3 | 1.8 | 12 | 5 |

| BS 0601 B | 13 | 14 | 3 | 1.8 | 10 | 2 |

| BS 0601.5 B | 14 | 16 | 3 | 1.8 | 10 | 3 |

| BS 0602 A | 15 | 15 | 3 | 1.8 | 10 | 2.5 |

| BS 0602 B | 15 | 18 | 3 | 1.8 | 12 | 3 |

| BS 0602.5 A | 15 | 16 | 3 | 1.8 | 10 | 3 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

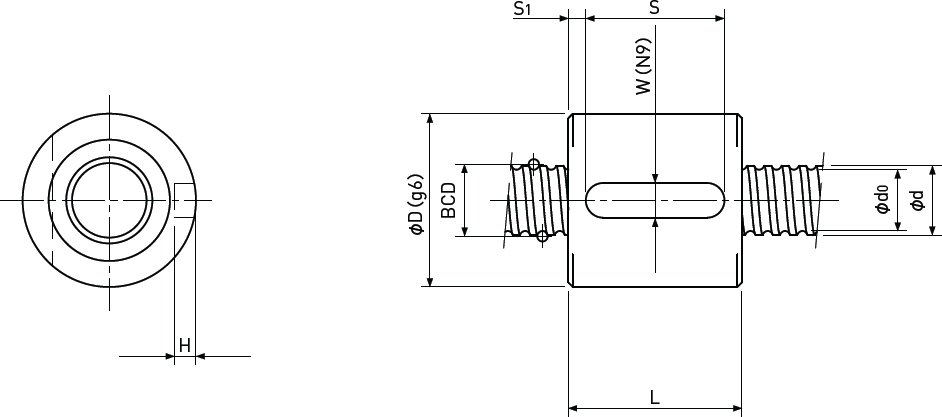

| Precision Ball Screws | |

|---|---|

Sleeve type Single Nut | Backlash type/Preload type |

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| BS 0801 B | 8 | 1 | 0.8 | 8.15 | 2°15' | 7.3 | 3.7×1 | 780 / 490 | 1650 / 820 | 95 / 80 |

| BS 0801.5 B | 8 | 1.5 | 1 | 8.2 | 3°20' | 7.1 | 3.7×1 | 1100 / 700 | 2200 / 1100 | 99 / 83 |

| BS 0802 A(1) | 8 | 2 | 1 | 8.2 | 4°26' | 7.1 | 2.7×1 | 850 / 540 | 1600 / 800 | 74 / 61 |

| BS 0802 B(1) | 8 | 2 | 1 | 8.2 | 4°26' | 7.1 | 3.7×1 | 1100 / 700 | 2200 / 1100 | 99 / 83 |

| BS 0802 A(2) | 8 | 2 | 1.5875 | 8.3 | 4°23' | 6.6 | 2.7×1 | 1850 / 1150 | 3000 / 1500 | 82 / 69 |

| BS 0802 B(2) | 8 | 2 | 1.5875 | 8.3 | 4°23' | 6.6 | 3.7×1 | 2400 / 1550 | 4100 / 2100 | 111 / 94 |

| BS 0802.5 A(1) | 8 | 2.5 | 1.5875 | 8 | 5°41' | 6.3 | 2.7×1 | 1850 / - | 3000 / - | 80 / - |

| BS 0802.5 A(2) | 8 | 2.5 | 1.5875 | 8.3 | 5°29' | 6.6 | 2.7×1 | 1850 / 1150 | 3000 / 1500 | 82 / 69 |

| BS 0802.5 B | 8 | 2.5 | 1.5875 | 8.3 | 5°29' | 6.6 | 3.7×1 | 2400 / 1550 | 4100 / 2100 | 111 / 93 |

| BS 0803 A | 8 | 3 | 2 | 8.3 | 6°34' | 6.2 | 2.7×1 | 2600 / 1650 | 4200 / 2100 | 85 / 70 |

| BS 0803 B | 8 | 3 | 2 | 8.3 | 6°34' | 6.2 | 3.7×1 | 3500 / 2200 | 5700 / 2800 | 116 / 97 |

| BS 0804 A | 8 | 4 | 2 | 8.3 | 8°43' | 6.2 | 2.7×1 | 2600 / 1650 | 4200 / 2100 | 84 / 70 |

| BS 0805 A | 8 | 5 | 1.5875 | 8.3 | 10°51' | 6.6 | 2.7×1 | 1850 / 1150 | 3000 / 1500 | 82 / 67 |

| Ball Nut Model number | Nut dimension | |||||

|---|---|---|---|---|---|---|

| D | L | W | H | S | S1 | |

| BS 0801 B | 16 | 14 | 3 | 1.8 | 10 | 2 |

| BS 0801.5 B | 16 | 16 | 3 | 1.8 | 10 | 3 |

| BS 0802 A(1) | 16 | 15 | 3 | 1.8 | 10 | 2.5 |

| BS 0802 B(1) | 16 | 18 | 3 | 1.8 | 12 | 3 |

| BS 0802 A(2) | 20 | 17 | 4 | 2.5 | 12 | 2.5 |

| BS 0802 B(2) | 20 | 20 | 4 | 2.5 | 16 | 2 |

| BS 0802.5 A(1) | 16 | 16 | 3 | 1.8 | 8 | 4 |

| BS 0802.5 A(2) | 20 | 19 | 4 | 2.5 | 12 | 3.5 |

| BS 0802.5 B | 20 | 22 | 4 | 2.5 | 16 | 3 |

| BS 0803 A | 20 | 22 | 4 | 2.5 | 16 | 3 |

| BS 0803 B | 20 | 26 | 4 | 2.5 | 20 | 3 |

| BS 0804 A | 21 | 26 | 4 | 2.5 | 20 | 3 |

| BS 0805 A | 18 | 28 | 4 | 2.5 | 20 | 4 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

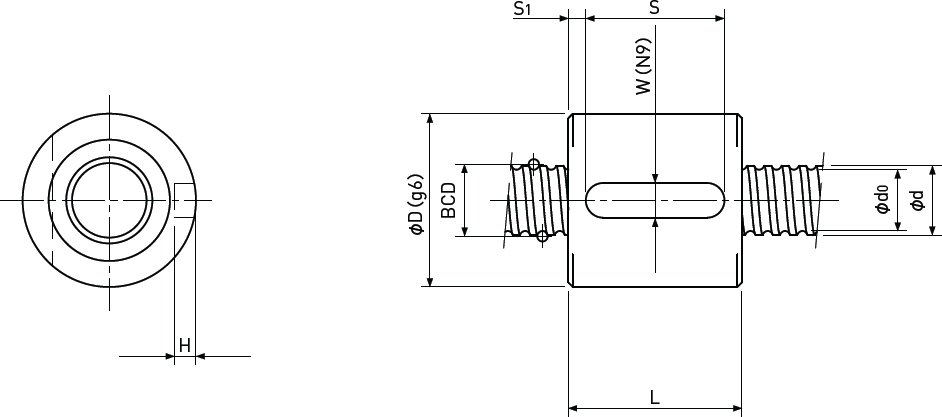

| Precision Ball Screws | |

|---|---|

Sleeve type Single Nut | Backlash type/Preload type |

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| BS 1001 B | 10 | 1 | 0.8 | 10.15 | 1°48' | 9.3 | 3.7×1 | 840 / 530 | 2000 / 1000 | 113 / 95 |

| BS 1001.5 B | 10 | 1.5 | 1 | 10.2 | 2°41' | 9.1 | 3.7×1 | 1250 / 790 | 2800 / 1400 | 120 / 101 |

| BS 1002 A | 10 | 2 | 1.5875 | 10.3 | 3°32' | 8.6 | 2.7×1 | 2100 / 1300 | 3800 / 1900 | 100 / 82 |

| BS1002 B | 10 | 2 | 1.5875 | 10.3 | 3°32' | 8.6 | 3.7×1 | 2700 / 1750 | 5300 / 2700 | 134 / 112 |

| BS 1002.5 A | 10 | 2.5 | 1.5875 | 10.3 | 4°25' | 8.6 | 2.7×1 | 2100 / 1300 | 3800 / 1900 | 100 / 82 |

| BS 1002.5 B | 10 | 2.5 | 1.5875 | 10.3 | 4°25' | 8.6 | 3.7×1 | 2700 / 1750 | 5300 / 2700 | 133 / 112 |

| BS 1003 A | 10 | 3 | 2 | 10.3 | 5°18' | 8.2 | 2.7×1 | 3000 / 1800 | 5200 / 2600 | 103 / 84 |

| BS 1003 B | 10 | 3 | 2 | 10.3 | 5°18' | 8.2 | 3.7×1 | 3900 / 2500 | 7200 / 3600 | 140 / 118 |

| BS 1004 A | 10 | 4 | 2 | 10.3 | 7°03' | 8.2 | 2.7×1 | 3000 / 1800 | 5200 / 2600 | 104 / 86 |

| BS 1004 B | 10 | 4 | 2 | 10.3 | 7°03' | 8.2 | 3.7×1 | 3900 / 2500 | 7200 / 3600 | 139 / 118 |

| BS 1005 A(1) | 10 | 5 | 2 | 10.3 | 8°47' | 8.2 | 2.7×1 | 3000 / - | 5200 / - | 103 / - |

| BS 1005 A(2) | 10 | 5 | 2 | 10.3 | 8°47' | 8.2 | 2.70 ×1 | 3000 / 1800 | 5200 / 2600 | 103 / 85 |

| Ball Nut Model number | Nut dimension | |||||

|---|---|---|---|---|---|---|

| D | L | W | H | S | S1 | |

| BS 1001 B | 19 | 14 | 3 | 1.8 | 10 | 2 |

| BS 1001.5 B | 19 | 16 | 3 | 1.8 | 10 | 3 |

| BS 1002 A | 23 | 17 | 5 | 3 | 12 | 2.5 |

| BS1002 B | 23 | 20 | 5 | 3 | 16 | 2 |

| BS 1002.5 A | 24 | 19 | 5 | 3 | 12 | 3.5 |

| BS 1002.5 B | 24 | 22 | 5 | 3 | 16 | 3 |

| BS 1003 A | 24 | 22 | 5 | 3 | 16 | 3 |

| BS 1003 B | 24 | 26 | 5 | 3 | 20 | 3 |

| BS 1004 A | 24 | 26 | 5 | 3 | 20 | 3 |

| BS 1004 B | 24 | 30 | 5 | 3 | 20 | 5 |

| BS 1005 A(1) | 23 | 26 | 5 | 3 | 16 | 5 |

| BS 1005 A(2) | 24 | 34 | 5 | 3 | 28 | 3 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

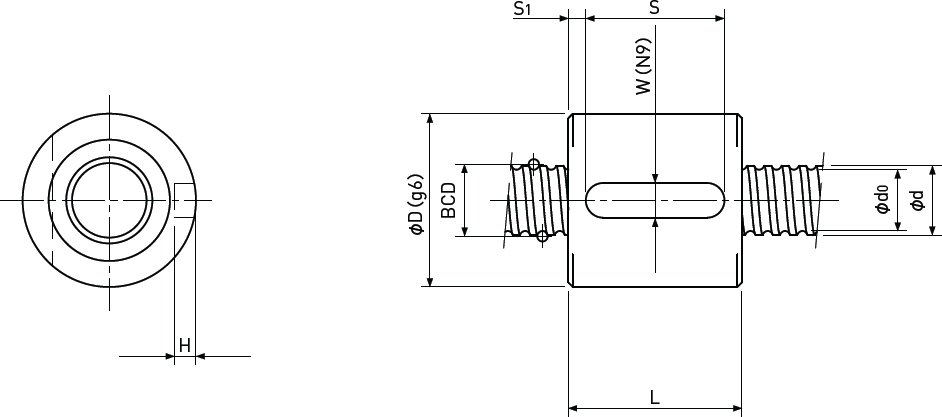

| Precision Ball Screws | |

|---|---|

Sleeve type Single Nut | Backlash type/Preload type |

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| BS 1201 B | 12 | 1 | 0.8 | 12.15 | 1°30' | 11.3 | 3.7×1 | 910 / 570 | 2400 / 1200 | 131 / 110 |

| BS 1202 B | 12 | 2 | 1.5875 | 12.3 | 2°58' | 10.6 | 3.7×1 | 3000 / 1900 | 6400 / 3200 | 156 / 132 |

| BS 1202.5 B | 12 | 2.5 | 1.5875 | 12.3 | 3°42' | 10.6 | 3.7×1 | 3000 / 1850 | 6400 / 3200 | 156 / 130 |

| BS 1203 B | 12 | 3 | 2 | 12.3 | 4°26' | 10.2 | 3.7×1 | 4300 / 2800 | 8700 / 4300 | 162 / 137 |

| BS 1204 B | 12 | 4 | 2.381 | 12.3 | 5°55' | 9.8 | 3.7×1 | 5400 / 3400 | 10200 / 5100 | 165 / 139 |

| BS 1205 A | 12 | 5 | 2.381 | 12.3 | 7°22' | 9.8 | 2.7×1 | 4100 / 2500 | 7400 / 3700 | 122 / 101 |

| BS 1401 B | 14 | 1 | 0.8 | 14.15 | 1°17' | 13.3 | 3.7×1 | 960 / 610 | 2900 / 1450 | 148 / 124 |

| BS 1402 B | 14 | 2 | 1.5875 | 14.3 | 2°33' | 12.6 | 3.7×1 | 3200 / 2000 | 7500 / 3800 | 176 / 148 |

| BS 1402.5 B | 14 | 2.5 | 1.5875 | 14.3 | 3°11' | 12.6 | 3.7×1 | 3200 / 2000 | 7500 / 3700 | 176 / 148 |

| BS 1403 B | 14 | 3 | 2 | 14.3 | 3°49' | 12.2 | 3.7×1 | 4600 / 2900 | 10100 / 5000 | 184 / 154 |

| BS 1404 B | 14 | 4 | 2.381 | 14.3 | 5°05' | 11.8 | 3.7×1 | 5700 / 3600 | 11600 / 5800 | 187 / 157 |

| BS 1405 B | 14 | 5 | 2.381 | 14.3 | 6°21' | 11.8 | 3.7×1 | 5700 / 3600 | 11600 / 5800 | 186 / 157 |

| Ball Nut Model number | Nut dimension | |||||

|---|---|---|---|---|---|---|

| D | L | W | H | S | S1 | |

| BS 1201 B | 22 | 14 | 4 | 2.5 | 10 | 2 |

| BS 1202 B | 25 | 20 | 5 | 3 | 16 | 2 |

| BS 1202.5 B | 26 | 22 | 5 | 3 | 16 | 3 |

| BS 1203 B | 28 | 26 | 5 | 3 | 20 | 3 |

| BS 1204 B | 28 | 31 | 5 | 3 | 25 | 3 |

| BS 1205 A | 28 | 31 | 5 | 3 | 25 | 3 |

| BS 1401 B | 26 | 16 | 5 | 3 | 10 | 3 |

| BS 1402 B | 26 | 20 | 5 | 3 | 16 | 2 |

| BS 1402.5 B | 28 | 22 | 5 | 3 | 16 | 3 |

| BS 1403 B | 30 | 26 | 5 | 3 | 20 | 3 |

| BS 1404 B | 30 | 31 | 5 | 3 | 25 | 3 |

| BS 1405 B | 30 | 38 | 5 | 3 | 28 | 5 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

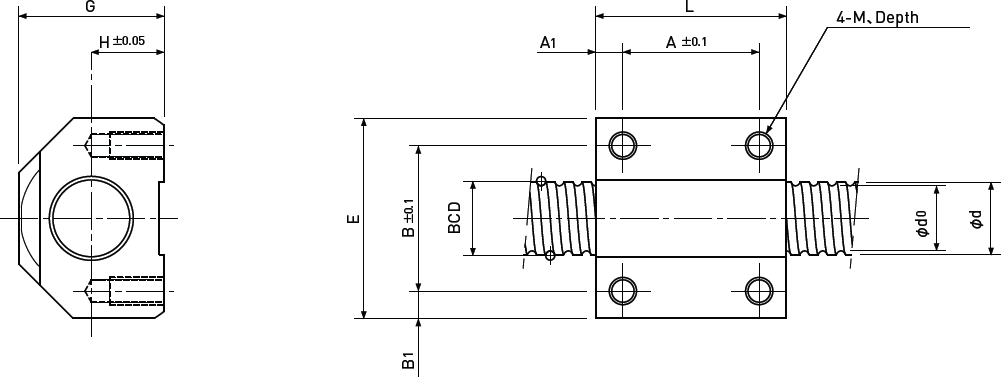

| Precision Ball Screws | |

|---|---|

Sleeve type Single Nut | Backlash type/Preload type |

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| BS 1601 B | 16 | 1 | 0.8 | 16.15 | 1°08' | 15.3 | 3.7×1 | 1000 / 640 | 3300 / 1650 | 164 / 138 |

| BS 1602 B | 16 | 2 | 1.5875 | 16.3 | 2°14' | 14.6 | 3.7×1 | 3400 / 2100 | 8600 / 4300 | 197 / 163 |

| BS 1602.5 B | 16 | 2.5 | 1.5875 | 16.3 | 2°48' | 14.6 | 3.7×1 | 3400 / 2100 | 8600 / 4300 | 197 / 163 |

| BS 1603 B | 16 | 3 | 2 | 16.3 | 3°21' | 14.2 | 3.7×1 | 4900 / 3100 | 11600 / 5800 | 205 / 172 |

| BS 1604 B | 16 | 4 | 2.381 | 16.3 | 4°28' | 13.8 | 3.7×1 | 6200 / 3900 | 13600 / 6800 | 209 / 174 |

| BS 1605 B | 16 | 5 | 3.175 | 16.5 | 5°31' | 13.2 | 3.7×1 | 9100 / 5700 | 18200 / 9100 | 217 / 182 |

| Ball Nut Model number | Nut dimension | |||||

|---|---|---|---|---|---|---|

| D | L | W | H | S | S1 | |

| BS 1601 B | 28 | 16 | 5 | 3 | 10 | 3 |

| BS 1602 B | 28 | 20 | 5 | 3 | 16 | 2 |

| BS 1602.5 B | 28 | 22 | 5 | 3 | 16 | 3 |

| BS 1603 B | 32 | 26 | 5 | 3 | 20 | 3 |

| BS 1604 B | 34 | 32 | 5 | 3 | 25 | 3.5 |

| BS 1605 B | 38 | 38 | 5 | 3 | 28 | 5 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

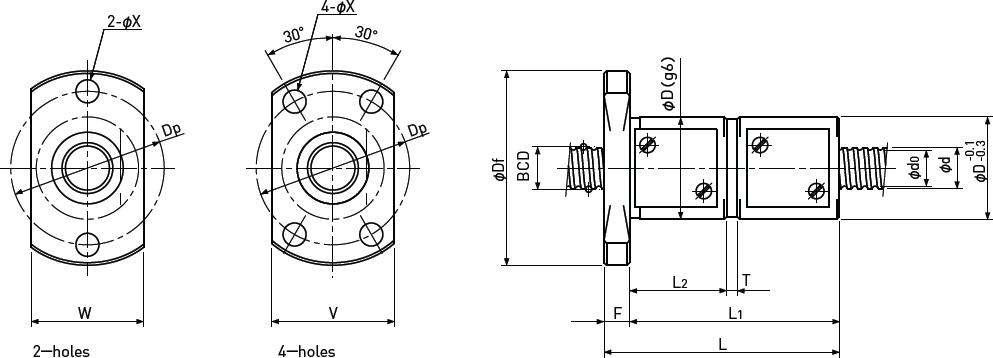

| Precision Ball Screws | |

|---|---|

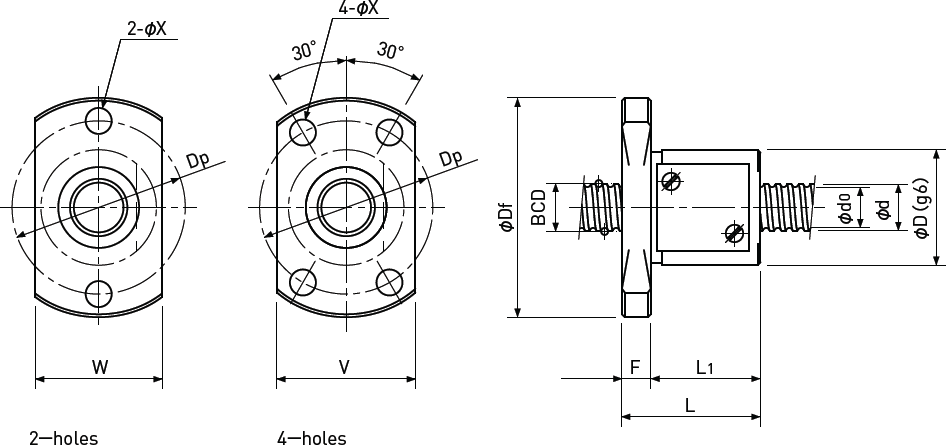

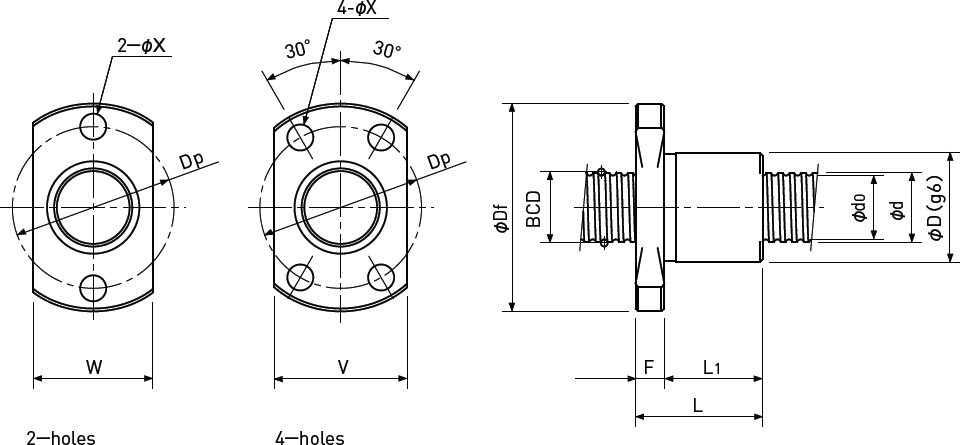

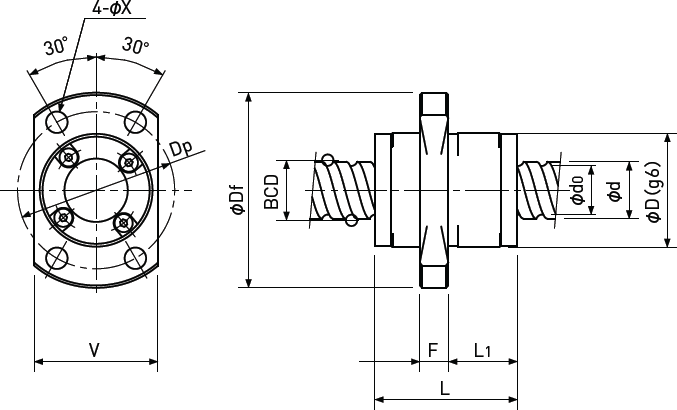

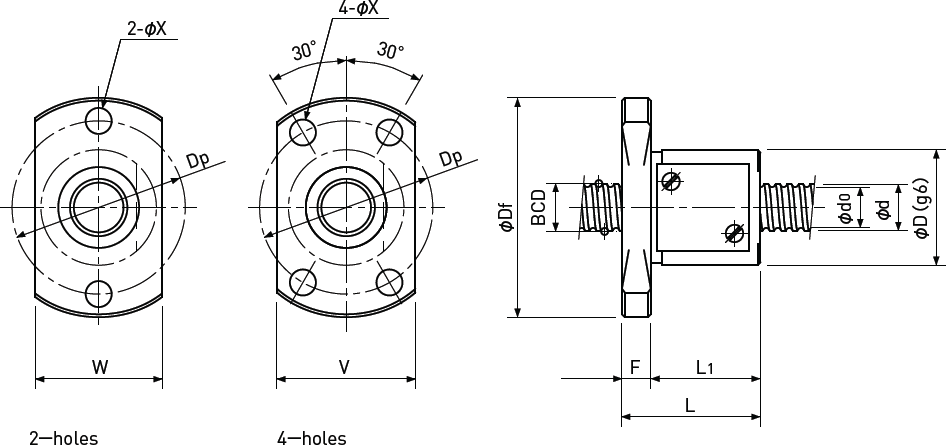

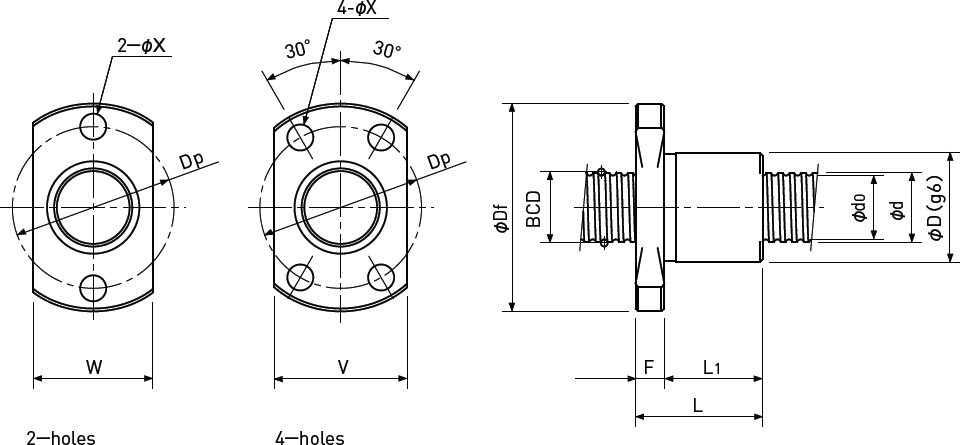

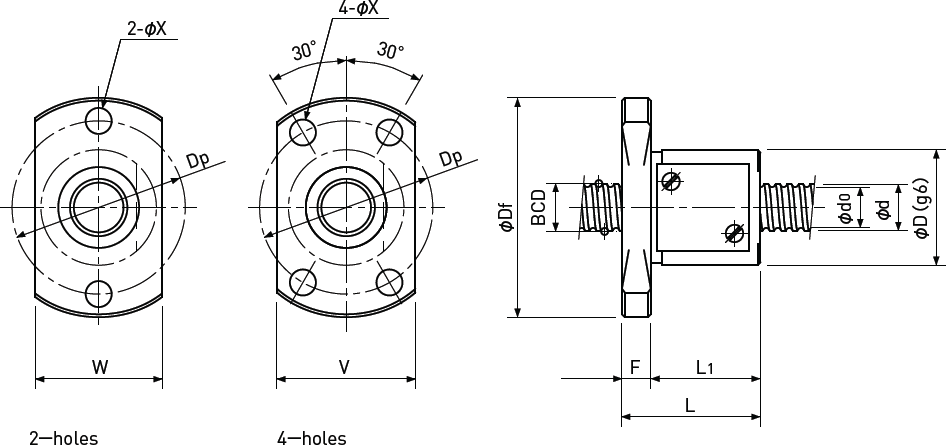

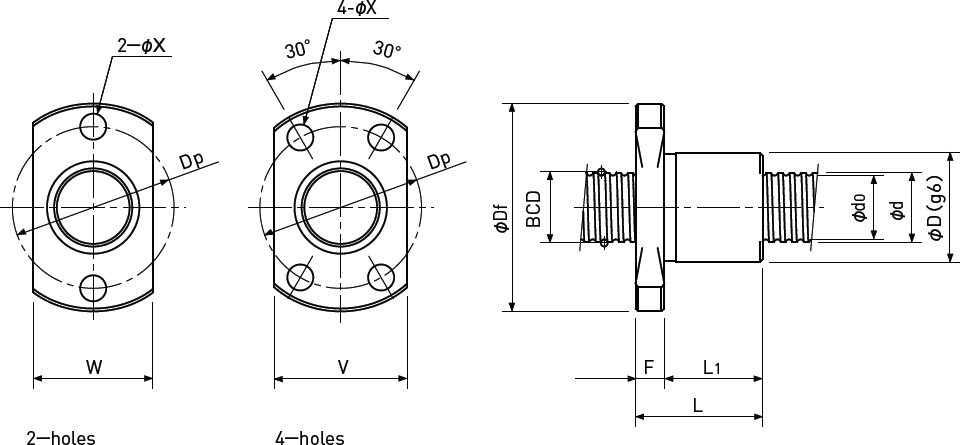

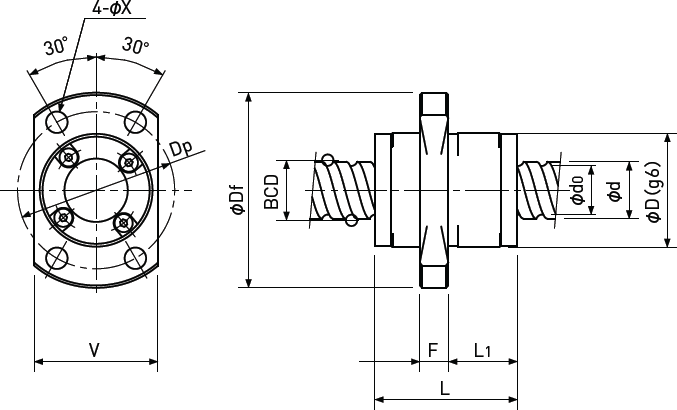

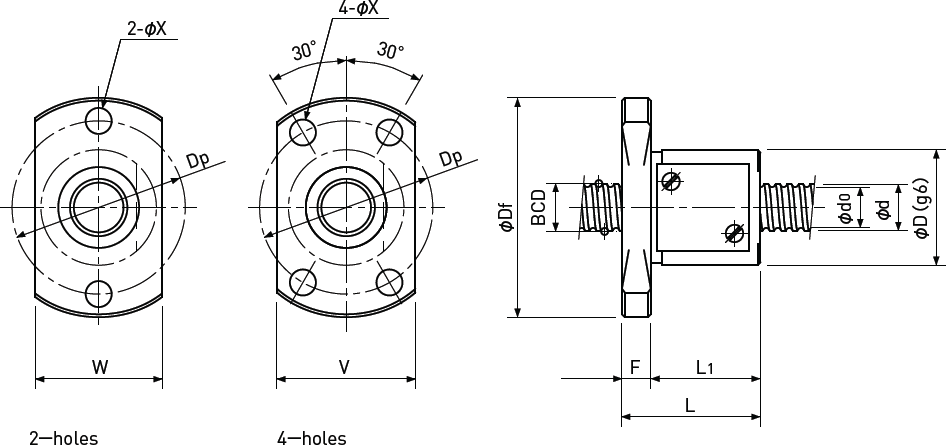

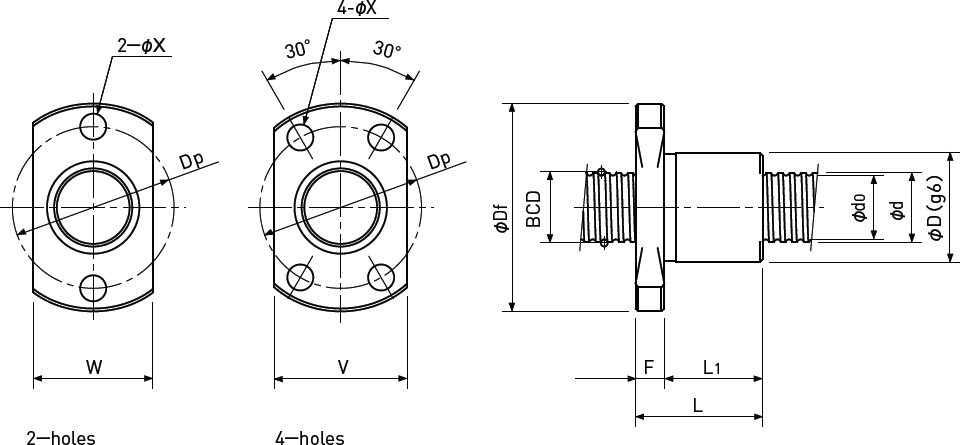

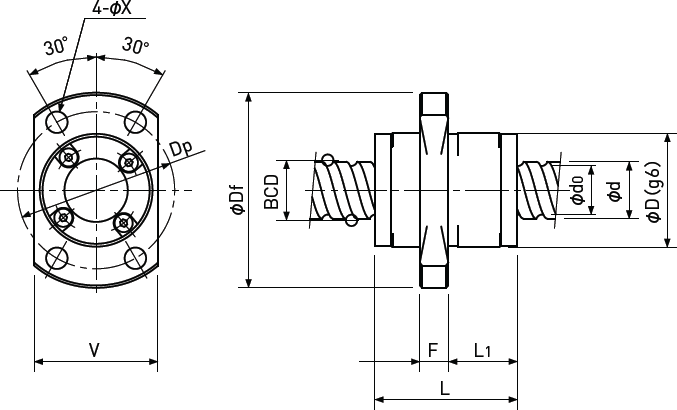

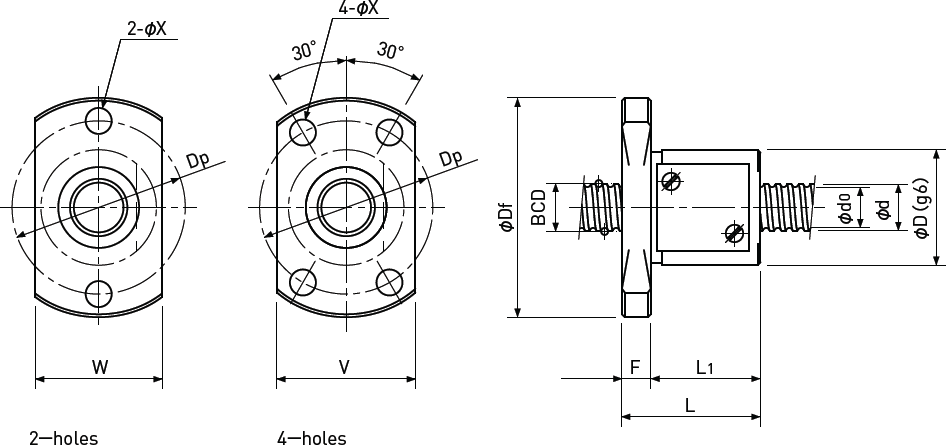

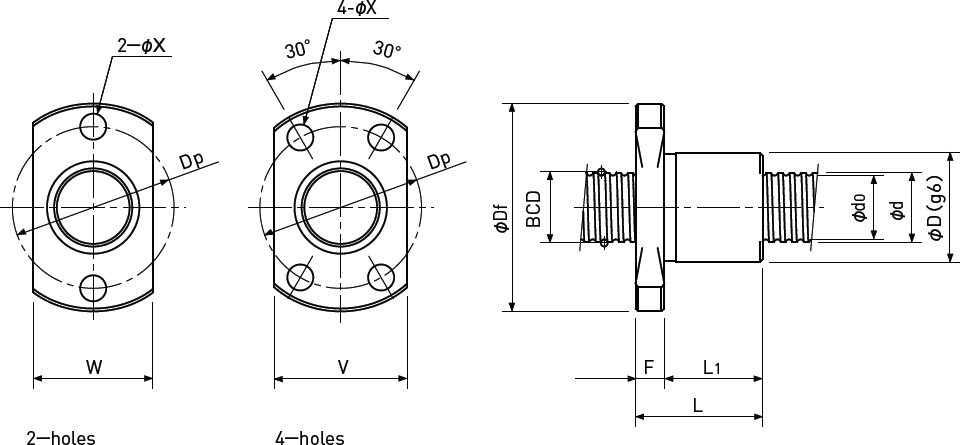

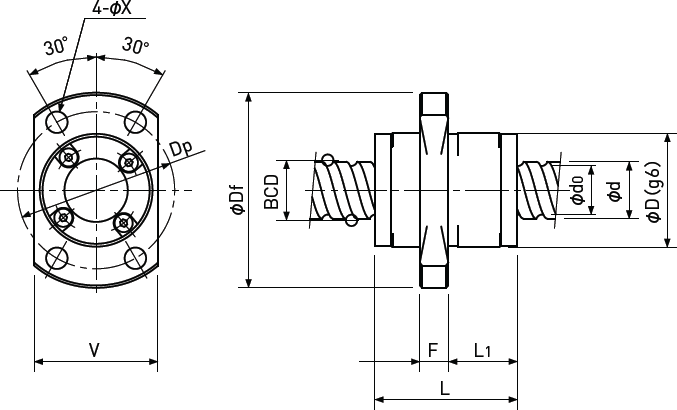

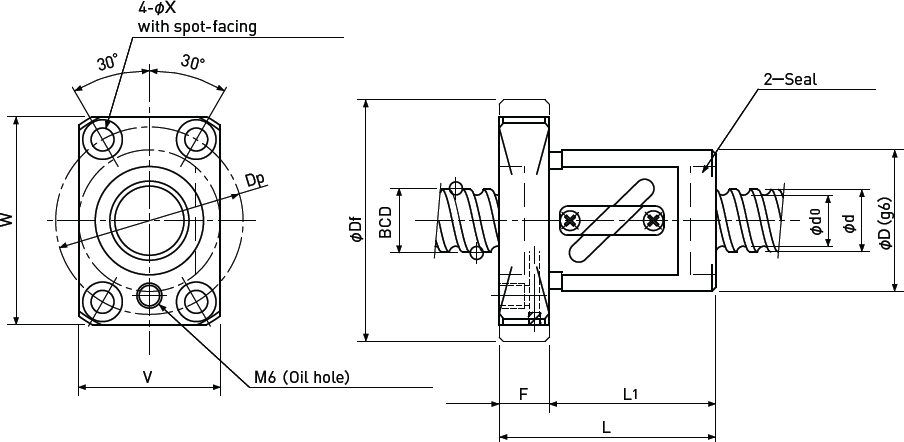

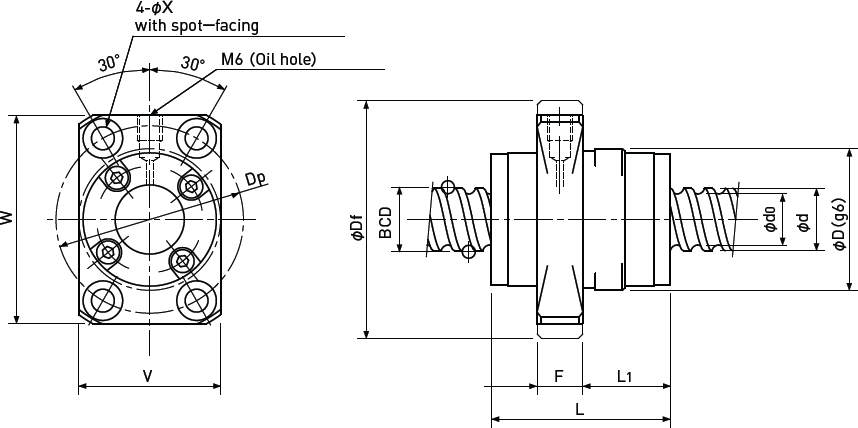

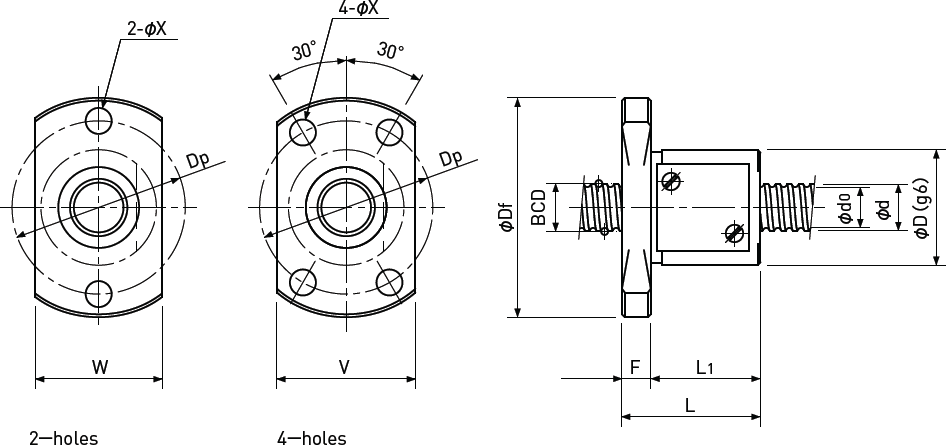

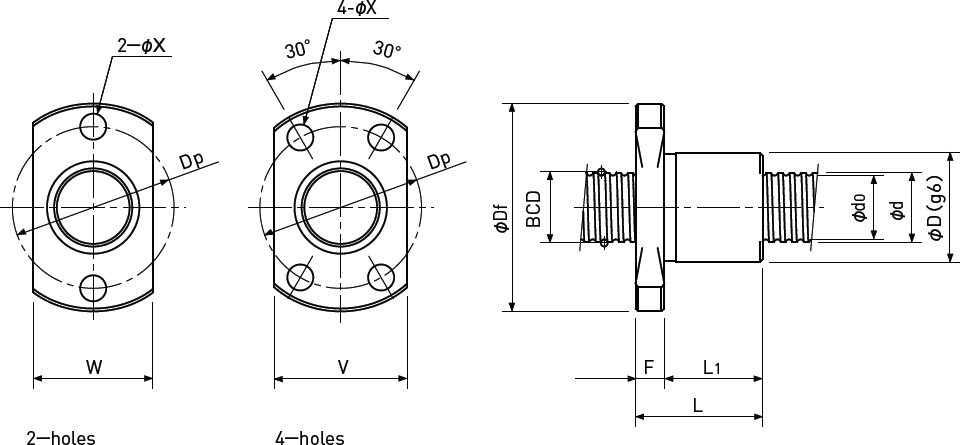

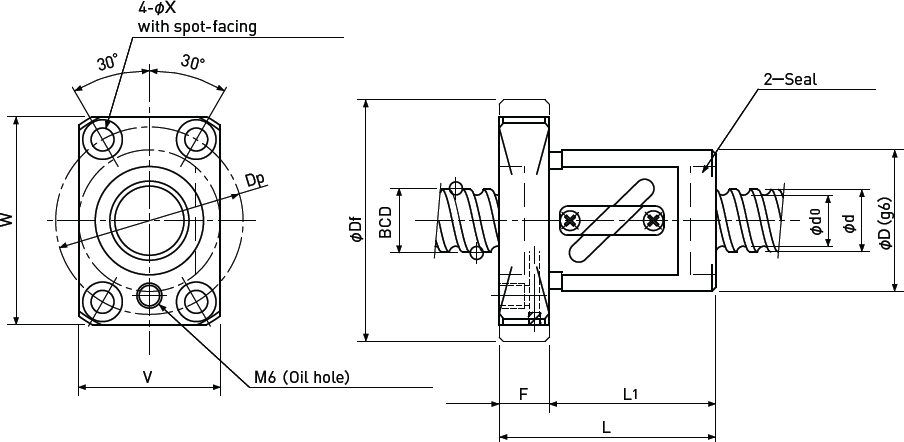

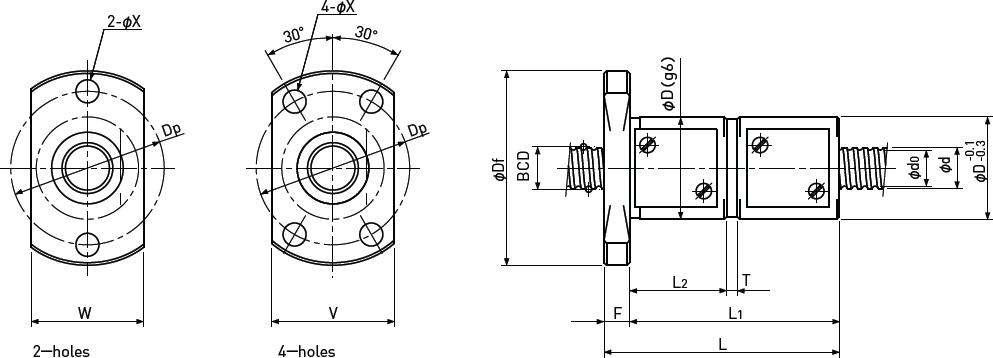

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FBS 01800.5 A | 1.8 | 0.5 | 0.4 | 1.95 | 4°40' | 1.5 | 2.7×1 | 110 / - | 130 / - | 19 / - |

| FBS 0300.5 A | 3 | 0.5 | 0.4 | 3.1 | 2°56' | 2.6 | 2.7×1 | 150 / - | 220 / - | 29 / - |

| FBS 0301 B | 3 | 1 | 0.6 | 3.18 | 5°43' | 2.4 | 3.7×1 | 330 / - | 440 / - | 42 / - |

| FBS 0400.5 A | 4 | 0.5 | 0.4 | 4.1 | 2°13' | 3.6 | 2.7×1 | 160 / - | 290 / - | 36 / - |

| FKB 0401 A | 4 | 1 | 0.6 | 4.15 | 4°23' | 3.4 | 1×3 | 300 / 300 | 430 / 430 | 38 / 59 |

| FBS 0401 A | 4 | 1 | 0.8 | 4.15 | 4°23' | 3.3 | 2.7×1 | 420 / 270 | 570 / 290 | 40 / 34 |

| FBS 0401 B | 4 | 1 | 0.8 | 4.15 | 4°23' | 3.3 | 3.7×1 | 560 / 350 | 790 / 400 | 54 / 45 |

| FBS 0402 A | 4 | 2 | 0.8 | 4.15 | 8°43' | 3.3 | 2.7×1 | 420 / 260 | 570 / 290 | 39 / 33 |

| FBS 0403 A | 4 | 3 | 0.8 | 4.15 | 12°57' | 3.3 | 2.7×1 | 420 / - | 570 / - | 39 / - |

| FEB 0404 A | 4 | 4 | 0.8 | 4.2 | 16°51' | 3.3 | 2.6×2 | 750 / - | 1150 / - | 73 / - |

| Ball Nut Model number | Nut dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut type | D | Df | L | L1 | F | W | V | Dp | Bolt Hole X | |

| FBS 01800.5 A | 1 | 6 | 14 | 8.5 | 7 | 1.5 | 8 | - | 10 | 2.4 |

| FBS 0300.5 A | 1 | 8 | 16 | 11 | 8 | 3 | 8 | - | 12 | 2.4 |

| FBS 0301 B | 1 | 9 | 19 | 14 | 11 | 3 | 11 | - | 14 | 2.9 |

| FBS 0400.5 A | 1 | 10 | 20 | 13 | 10 | 3 | 12 | - | 15 | 2.9 |

| FKB 0401 A | 2 | 9 | 19 | 13 | 10 | 3 | 11 | 13 | 14 | 2.9 |

| FBS 0401 A | 1 | 10 | 20 | 12 | 9 | 3 | 12 | 14 | 15 | 2.9 |

| FBS 0401 B | 1 | 11 | 23 | 17 | 13 | 4 | 13 | 15 | 17 | 3.4 |

| FBS 0402 A | 1 | 11 | 23 | 19 | 15 | 4 | 13 | 15 | 17 | 3.4 |

| FBS 0403 A | 1 | 11 | 23 | 21 | 17 | 4 | 13 | 15 | 17 | 3.4 |

| FEB 0404 A | 3 | 11 | 23 | 17.5 | 11 | 3 | - | 15 | 17 | 3.4 |

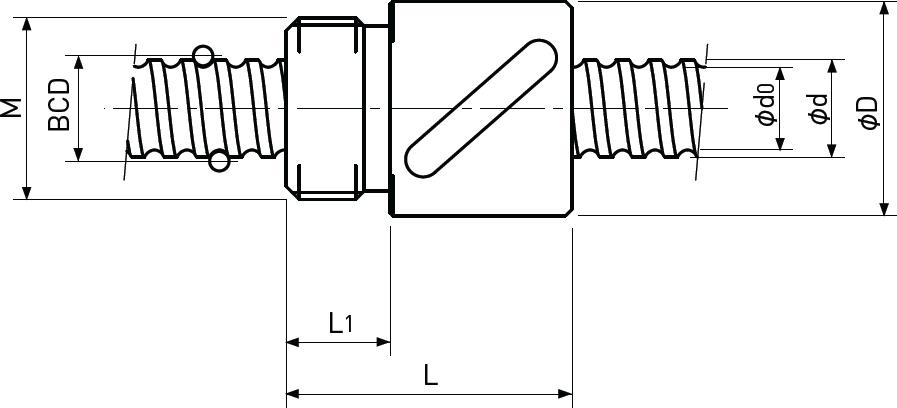

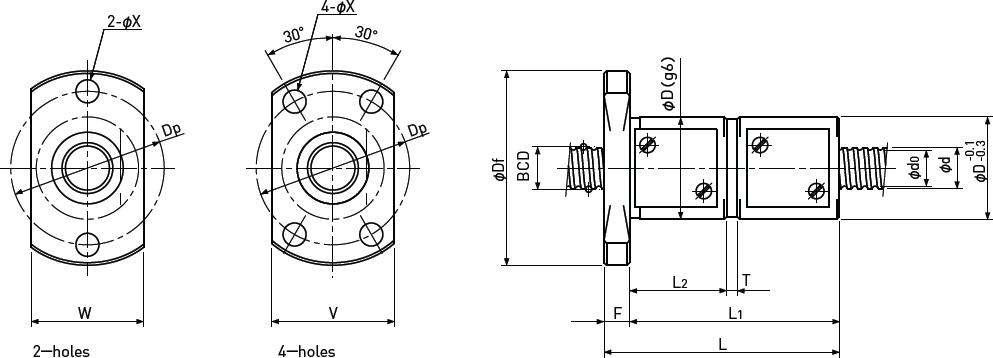

| Precision Ball Screws | |

|---|---|

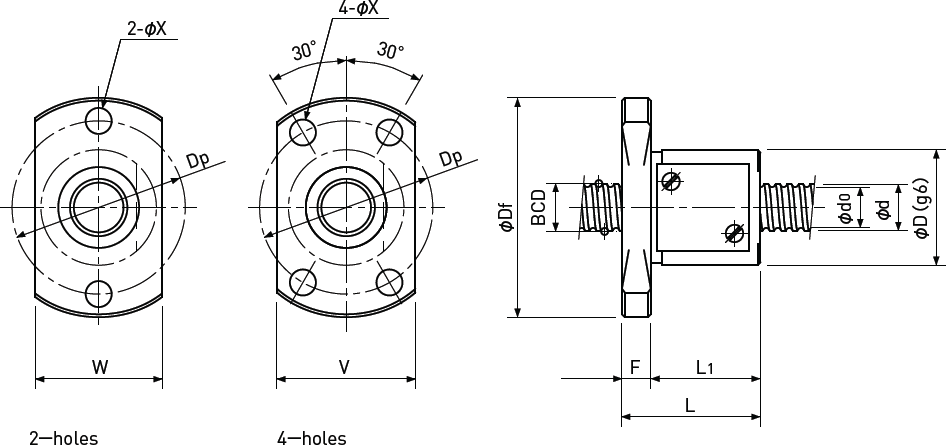

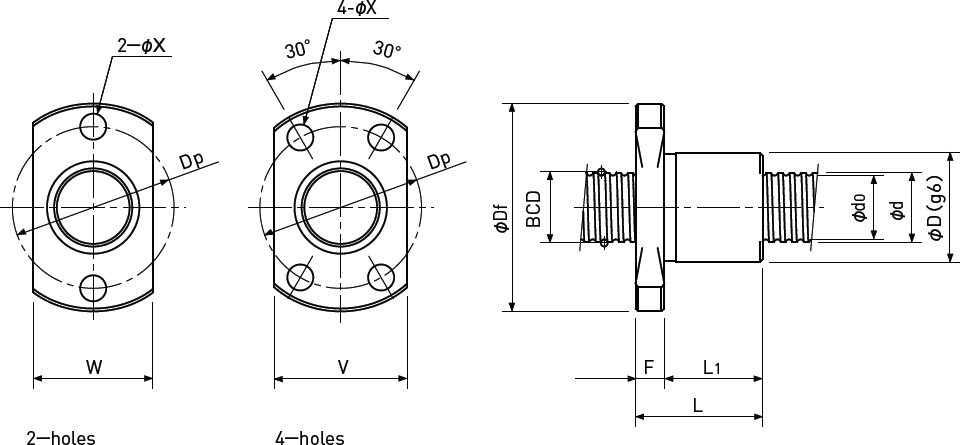

Single Nut with Flange | Backlash type/Preload type |

Type-2: Internal-deflector type or End-deflector type

Type-3: End-cap type or End-deflector type

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FBS 0500.5 A | 5 | 0.5 | 0.4 | 5.1 | 1°47' | 4.6 | 2.7×1 | 180 / - | 370 / - | 44 / - |

| FKB 0501 A | 5 | 1 | 0.6 | 5.15 | 3°32' | 4.4 | 1×3 | 330 / 330 | 560 / 560 | 45 / 70 |

| FBS 0501 B | 5 | 1 | 0.8 | 5.15 | 3°32' | 4.3 | 3.7×1 | 630 / 400 | 1000 / 500 | 65 / 55 |

| FBS 0504 A | 5 | 4 | 0.8 | 5.15 | 13°53' | 4.3 | 2.7×1 | 470 / 300 | 720 / 360 | 47 / 39 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-2: Internal-deflector type or End-deflector type

| Ball Nut Model number | Nut dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut type | D | Df | L | L1 | F | W | V | Dp | Bolt Hole X | |

| FBS 0500.5 A | 1 | 11 | 23 | 13 | 10 | 3 | 13 | - | 17 | 3.4 |

| FKB 0501 A | 2 | 10 | 20 | 13 | 10 | 3 | 12 | 14 | 15 | 2.9 |

| FBS 0501 B | 1 | 12 | 24 | 17 | 13 | 4 | 14 | 15 | 18 | 3.4 |

| FBS 0504 A | 1 | 12 | 24 | 22 | 18 | 4 | 14 | 15 | 18 | 3.4 |

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FBS 0600.5 A | 6 | 0.5 | 0.4 | 6.1 | 1°30' | 5.6 | 2.7×1 | 190 / - | 440 / - | 50 / - |

| FKB 0601 A | 6 | 1 | 0.8 | 6.2 | 2°56' | 5.3 | 1×3 | 560 / 560 | 950 / 950 | 55 / 86 |

| FBS 0601 B | 6 | 1 | 0.8 | 6.15 | 2°58' | 5.3 | 3.7×1 | 680 / 430 | 1200 / 610 | 75 / 63 |

| FBS 0601.5 B | 6 | 1.5 | 1 | 6.2 | 4°24' | 5.1 | 3.7×1 | 980 / 620 | 1600 / 800 | 79 / 67 |

| FBS 0602 A | 6 | 2 | 1 | 6.2 | 5°52' | 5.1 | 2.7×1 | 750 / 470 | 1200 / 590 | 58 / 49 |

| FBS 0602 B | 6 | 2 | 1 | 6.2 | 5°52' | 5.1 | 3.7×1 | 980 / 620 | 1600 / 800 | 79 / 67 |

| FBS 0602.5 A | 6 | 2.5 | 1 | 6.2 | 7°19' | 5.1 | 2.7×1 | 750 / 470 | 1200 / 590 | 59 / 49 |

| FEB 0606 A | 6 | 6 | 1 | 6.3 | 16°52' | 5.2 | 1.6×2 | 870 / - | 1450 / - | 67 / - |

| FEB 0610 A | 6 | 10 | 1.2 | 6.3 | 26°48' | 5 | 1.2×2 | 950 / - | 1600 / - | 50 / - |

| FEB 0612 A | 6 | 12 | 1.2 | 6.3 | 31°13' | 5 | 0.7×2 | 600 / - | 950 / - | 29 / - |

| Ball Nut Model number | Nut dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut type | D | Df | L | L1 | F | W | V | Dp | Bolt Hole X | |

| FBS 0600.5 A | 1 | 12 | 25 | 13 | 10 | 3 | 14 | - | 19 | 3.4 |

| FKB 0601 A | 2 | 11 | 23 | 14.5 | 11 | 3.5 | 13 | 15 | 17 | 3.4 |

| FBS 0601 B | 1 | 13 | 28 | 17 | 13 | 4 | 15 | 17 | 21.5 | 3.4 |

| FBS 0601.5 B | 1 | 14 | 28 | 19 | 15 | 4 | 16 | 17 | 22 | 3.4 |

| FBS 0602 A | 1 | 15 | 29 | 17 | 13 | 4 | 17 | 18 | 23 | 3.4 |

| FBS 0602 B | 1 | 15 | 29 | 21 | 17 | 4 | 17 | 18 | 23 | 3.4 |

| FBS 0602.5 A | 1 | 15 | 29 | 18 | 14 | 4 | 17 | 18 | 23 | 3.4 |

| FEB 0606 A | 3 | 14 | 27 | 17 | 8 | 4 | - | 16 | 21 | 3.4 |

| FEB 0610 A | 3 | 14 | 27 | 23 | 11.5 | 4 | - | 16 | 21 | 3.4 |

| FEB 0612 A | 3 | 14 | 27 | 16 | 8.3 | 4 | - | 16 | 21 | 3.4 |

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-2: Internal-deflector type or End-deflector type

Type-3: End-cap type or End-deflector type

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

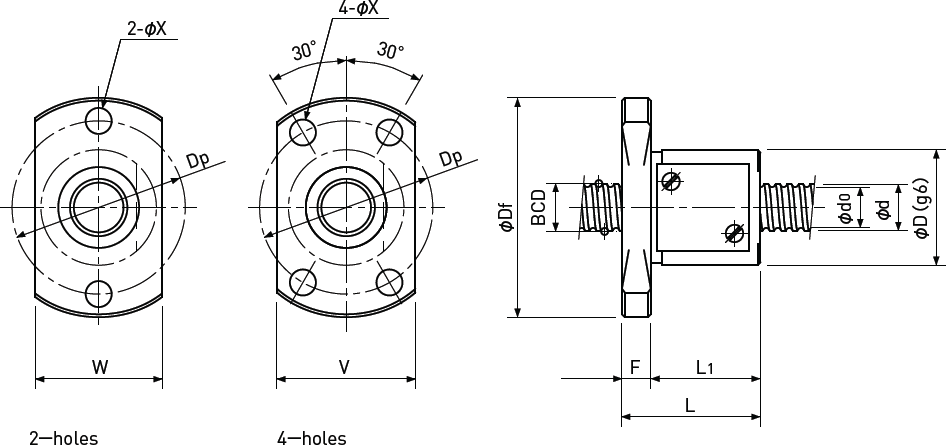

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FBS 0800.5 A | 8 | 0.5 | 0.4 | 8.1 | 1°08' | 7.6 | 2.7×1 | 220 / - | 590 / - | 64 / - |

| FKB 0801 A | 8 | 1 | 0.8 | 8.2 | 2°13' | 7.3 | 1×3 | 650 / 650 | 1300 / 1300 | 70 / 109 |

| FBS 0801 B | 8 | 1 | 0.8 | 8.15 | 2°15' | 7.3 | 3.7×1 | 780 / 490 | 1650 / 820 | 95 / 80 |

| FKB 0801.5 A | 8 | 1.5 | 1 | 8.3 | 3°18' | 7.2 | 1×3 | 890 / 890 | 1650 / 1650 | 73 / 113 |

| FBS 0801.5 B | 8 | 1.5 | 1 | 8.2 | 3°20' | 7.1 | 3.7×1 | 1100 / 700 | 2200 / 1100 | 99 / 83 |

| FKB 0802 A | 8 | 2 | 1.2 | 8.3 | 4°23' | 7 | 1×3 | 1300 / 1300 | 2300 / 2300 | 77 / 121 |

| FBS 0802 A(1) | 8 | 2 | 1 | 8.2 | 4°26' | 7.1 | 2.7×1 | 850 / 540 | 1600 / 800 | 74 / 61 |

| FBS 0802 B(1) | 8 | 2 | 1 | 8.2 | 4°26' | 7.1 | 3.7×1 | 1100 / 700 | 2200 / 1100 | 99 / 83 |

| FBS 0802 A(2) | 8 | 2 | 1.5875 | 8.3 | 4°23' | 6.6 | 2.7×1 | 1850 / 1150 | 3000 / 1500 | 82 / 69 |

| FBS 0802 B(2) | 8 | 2 | 1.5875 | 8.3 | 4°23' | 6.6 | 3.7×1 | 2400 / 1550 | 4100 / 2100 | 111 / 94 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-2: Internal-deflector type or End-deflector type

| Ball Nut Model number | Nut dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut type | D | Df | L | L1 | F | W | V | Dp | Bolt Hole X | |

| FBS 0800.5 A | 1 | 14 | 27 | 13 | 10 | 3 | 16 | - | 21 | 3.4 |

| FKB 0801 A | 2 | 13 | 26 | 15 | 11 | 4 | 15 | 17 | 20 | 3.4 |

| FBS 0801 B | 1 | 16 | 30 | 17 | 13 | 4 | 18 | 18 | 24 | 3.4 |

| FKB 0801.5 A | 2 | 15 | 28 | 20 | 16 | 4 | 17 | 19 | 22 | 3.4 |

| FBS 0801.5 B | 1 | 16 | 30 | 19 | 15 | 4 | 18 | 18 | 24 | 3.4 |

| FKB 0802 A | 2 | 15 | 28 | 18 | 14 | 4 | 17 | 19 | 22 | 3.4 |

| FBS 0802 A(1) | 1 | 16 | 30 | 17 | 13 | 4 | 18 | 18 | 24 | 3.4 |

| FBS 0802 B(1) | 1 | 16 | 30 | 21 | 17 | 4 | 18 | 18 | 24 | 3.4 |

| FBS 0802 A(2) | 1 | 20 | 38 | 21 | 16 | 5 | 22 | 23 | 30 | 4.5 |

| FBS 0802 B(2) | 1 | 20 | 38 | 24 | 19 | 5 | 22 | 23 | 30 | 4.5 |

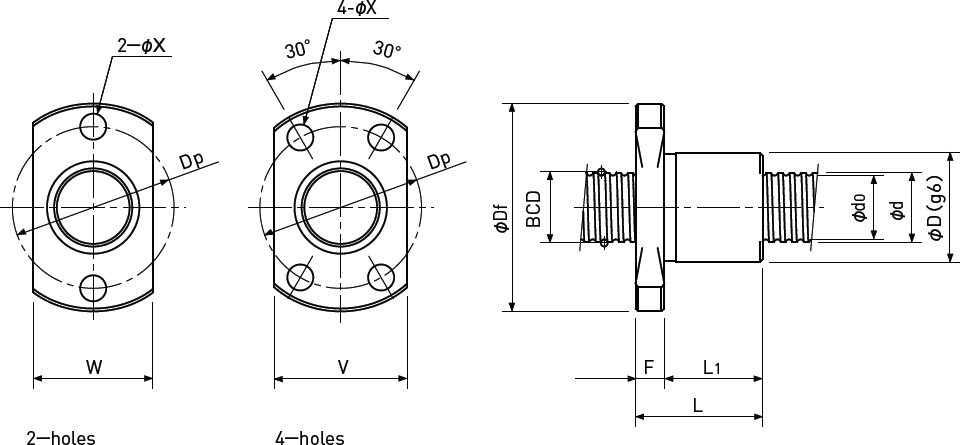

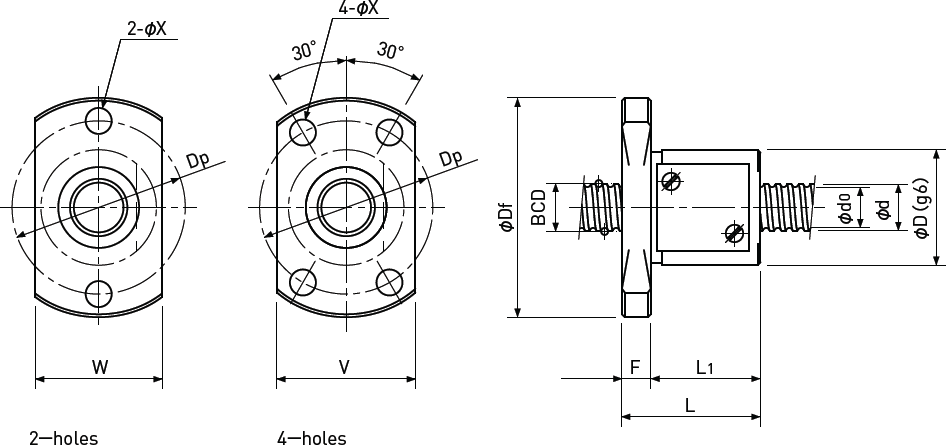

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FDB 0802.5 A | 8 | 2.5 | 1.5875 | 8 | 5°41' | 6.3 | 2.7×1 | 1850 / - | 3000 / - | 80 / - |

| FBS 0802.5 A | 8 | 2.5 | 1.5875 | 8.3 | 5°29' | 6.6 | 2.7×1 | 1850 / 1150 | 3000 / 1500 | 82 / 69 |

| FBS 0802.5 B | 8 | 2.5 | 1.5875 | 8.3 | 5°29' | 6.6 | 3.7×1 | 2400 / 1550 | 4100 / 2100 | 111 / 93 |

| FBS 0803 A | 8 | 3 | 2 | 8.3 | 6°34' | 6.2 | 2.7×1 | 2600 / 1650 | 4200 / 2100 | 85 / 70 |

| FBS 0803 B | 8 | 3 | 2 | 8.3 | 6°34' | 6.2 | 3.7×1 | 3500 / 2200 | 5700 / 2800 | 116 / 97 |

| FBS 0804 A | 8 | 4 | 2 | 8.3 | 8°43' | 6.2 | 2.7×1 | 2600 / 1650 | 4200 / 2100 | 84 / 70 |

| FBS 0805 A | 8 | 5 | 1.5875 | 8.3 | 10°51' | 6.6 | 2.7×1 | 1850 / 1150 | 3000 / 1500 | 82 / 67 |

| FEB 0808 A | 8 | 8 | 1.5875 | 8.4 | 16°52' | 6.7 | 1.6×2 | 2200 / - | 3800 / - | 95 / - |

| FEB 0810 A | 8 | 10 | 1.5875 | 8.4 | 20°45' | 6.7 | 1.6×2 | 2200 / - | 3900 / - | 92 / - |

| FEB 0812 A | 8 | 12 | 1.5875 | 8.4 | 24°27' | 6.7 | 1.6×2 | 2200 / - | 4000 / - | 90 / - |

| Ball Nut Model number | Nut dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut type | D | Df | L | L1 | F | W | V | Dp | Bolt Hole X | |

| FDB 0802.5 A | 2 | 16 | 29 | 16 | 12 | 4 | - | 18 | 23 | 3.4 |

| FBS 0802.5 A | 1 | 20 | 38 | 23 | 18 | 5 | 22 | 23 | 30 | 4.5 |

| FBS 0802.5 B | 1 | 20 | 38 | 26 | 21 | 5 | 22 | 23 | 30 | 4.5 |

| FBS 0803 A | 1 | 20 | 38 | 25 | 20 | 5 | 22 | 23 | 30 | 4.5 |

| FBS 0803 B | 1 | 20 | 38 | 29 | 24 | 5 | 22 | 23 | 30 | 4.5 |

| FBS 0804 A | 1 | 21 | 39 | 28 | 23 | 5 | 23 | 23 | 31 | 4.5 |

| FBS 0805 A | 1 | 18 | 31 | 28 | 24 | 4 | 20 | 20 | 25 | 3.4 |

| FEB 0808 A | 3 | 18 | 31 | 20 | 10 | 4 | - | 20 | 25 | 3.4 |

| FEB 0810 A | 3 | 18 | 31 | 24 | 13 | 4 | - | 20 | 25 | 3.4 |

| FEB 0812 A | 3 | 18 | 31 | 27 | 17 | 4 | - | 20 | 25 | 3.4 |

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-2: Internal-deflector type or End-deflector type

Type-3: End-cap type or End-deflector type

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

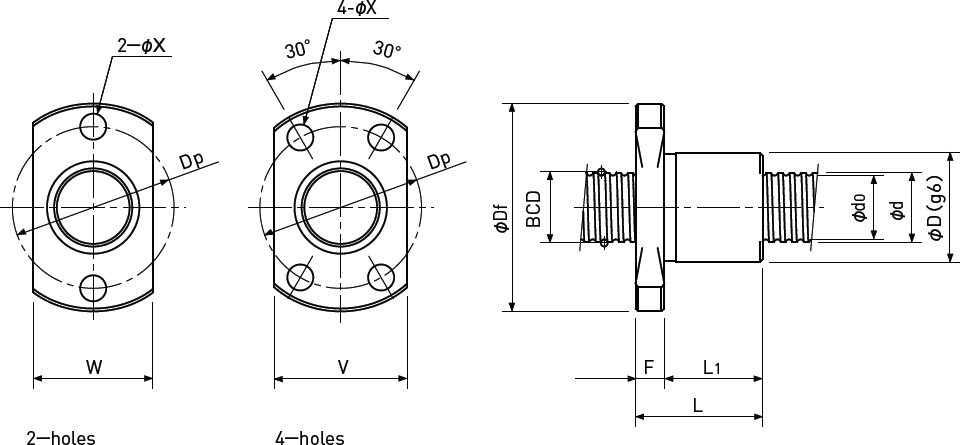

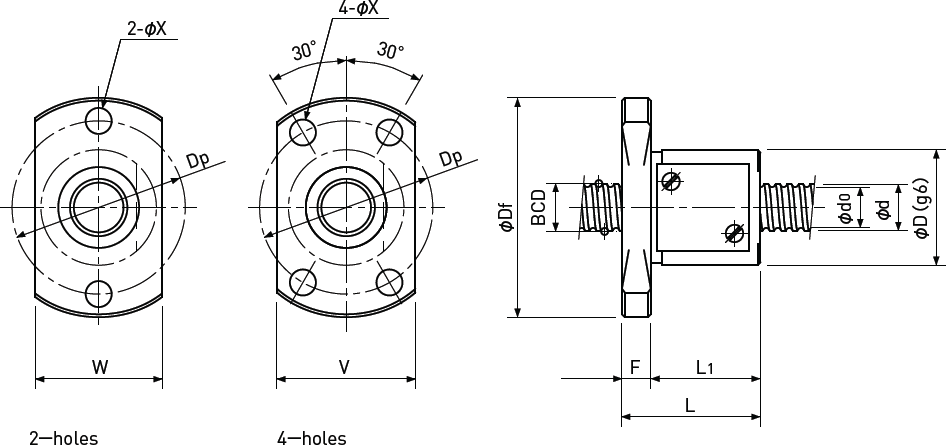

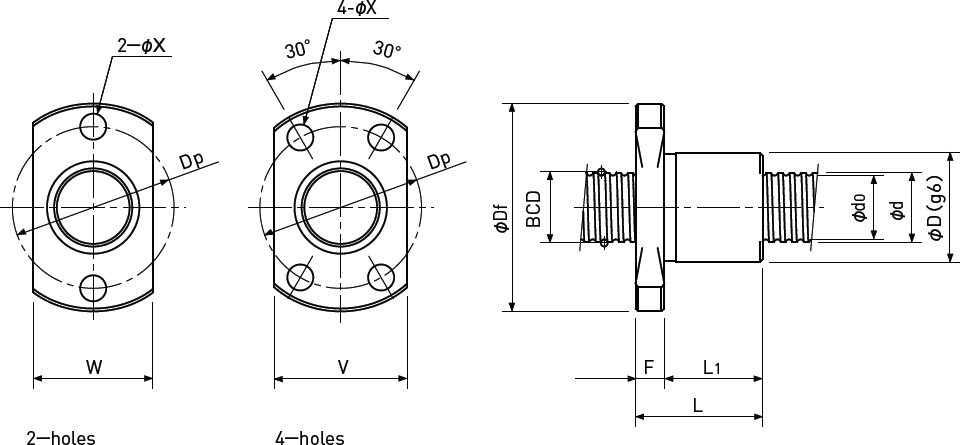

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FKB 1001 A | 10 | 1 | 0.8 | 10.2 | 1°47' | 9.3 | 1×3 | 720 / 720 | 1650 / 1650 | 84 / 131 |

| FBS 1001 B | 10 | 1 | 0.8 | 10.15 | 1°48' | 9.3 | 3.7×1 | 840 / 530 | 2000 / 1000 | 113 / 95 |

| FKB 1001.5 A | 10 | 1.5 | 1 | 10.3 | 2°39' | 9.2 | 1×3 | 990 / 990 | 2100 / 2100 | 87 / 136 |

| FBS 1001.5 B | 10 | 1.5 | 1 | 10.2 | 2°41' | 9.1 | 3.7×1 | 1250 / 790 | 2800 / 1400 | 120 / 101 |

| FKB 1002 A | 10 | 2 | 1.2 | 10.3 | 3°32' | 9 | 1×3 | 1450 / 1450 | 3000 / 3000 | 93 / 144 |

| FBS 1002 A | 10 | 2 | 1.5875 | 10.3 | 3°32' | 8.6 | 2.7×1 | 2100 / 1300 | 3800 / 1900 | 100 / 82 |

| FBS 1002 B | 10 | 2 | 1.5875 | 10.3 | 3°32' | 8.6 | 3.7×1 | 2700 / 1750 | 5300 / 2700 | 134 / 112 |

| FKB 1002.5 A | 10 | 2.5 | 1.5875 | 10.4 | 4°23' | 8.7 | 1×3 | 2100 / 2100 | 3800 / 3800 | 96 / 150 |

| FBS 1002.5 A | 10 | 2.5 | 1.5875 | 10.3 | 4°25' | 8.6 | 2.7×1 | 2100 / 1300 | 3800 / 1900 | 100 / 82 |

| FBS 1002.5 B | 10 | 2.5 | 1.5875 | 10.3 | 4°25' | 8.6 | 3.7×1 | 2700 / 1750 | 5300 / 2700 | 133 / 112 |

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-2: Internal-deflector type or End-deflector type

| Ball Nut Model number | Nut dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut type | D | Df | L | L1 | F | W | V | Dp | Bolt Hole X | |

| FKB 1001 A | 2 | 15 | 28 | 15 | 11 | 4 | 17 | 19 | 22 | 3.4 |

| FBS 1001 B | 1 | 19 | 37 | 18 | 13 | 5 | 21 | 22 | 29 | 4.5 |

| FKB 1001.5 A | 2 | 17 | 34 | 21 | 16 | 5 | 19 | 21 | 26 | 4.5 |

| FBS 1001.5 B | 1 | 19 | 37 | 20 | 15 | 5 | 21 | 22 | 29 | 4.5 |

| FKB 1002 A | 2 | 17 | 34 | 19 | 14 | 5 | 19 | 21 | 26 | 4.5 |

| FBS 1002 A | 1 | 23 | 41 | 21 | 16 | 5 | 25 | 25 | 33 | 4.5 |

| FBS 1002 B | 1 | 23 | 41 | 24 | 19 | 5 | 25 | 25 | 33 | 4.5 |

| FKB 1002.5 A | 2 | 18 | 35 | 21 | 16 | 5 | 20 | 22 | 27 | 4.5 |

| FBS 1002.5 A | 1 | 24 | 44 | 24 | 18 | 6 | 26 | 27 | 35 | 5.5 |

| FBS 1002.5 B | 1 | 24 | 44 | 27 | 21 | 6 | 26 | 27 | 35 | 5.5 |

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FBS 1003 A | 10 | 3 | 2 | 10.3 | 5°18' | 8.2 | 2.7×1 | 3000 / 1800 | 5200 / 2600 | 103 / 84 |

| FBS 1003 B | 10 | 3 | 2 | 10.3 | 5°18' | 8.2 | 3.7×1 | 3900 / 2500 | 7200 / 3600 | 140 / 118 |

| FBS 1004 A | 10 | 4 | 2 | 10.3 | 7°03' | 8.2 | 2.7×1 | 3000 / 1800 | 5200 / 2600 | 104 / 86 |

| FBS 1004 B | 10 | 4 | 2 | 10.3 | 7°03' | 8.2 | 3.7×1 | 3900 / 2500 | 7200 / 3600 | 139 / 118 |

| FDB 1005 A | 10 | 5 | 2 | 10.3 | 8°47' | 8.2 | 2.7×1 | 3000 / - | 5200 / - | 103 / - |

| FBS 1005 A | 10 | 5 | 2 | 10.3 | 8°47' | 8.2 | 2.7×1 | 3000 / 1800 | 5200 / 2600 | 103 / 85 |

| FEB 1010 A | 10 | 10 | 2 | 10.5 | 16°52' | 8.4 | 1.6×2 | 3300 / - | 5900 / - | 117 / - |

| FEB 1012 A | 10 | 12 | 2 | 10.5 | 19°59' | 8.4 | 1.6×2 | 3300 / - | 6200 / - | 115 / - |

| FEB 1015 A | 10 | 15 | 2 | 10.5 | 24°27' | 8.4 | 1.6×2 | 3300 / - | 6400 / - | 110 / - |

| FEB 1020 A | 10 | 20 | 1.5875 | 10.4 | 31°28' | 8.7 | 0.7×4 | 2100 / - | 4000 / - | 88 / - |

| FEB 1025 A | 10 | 25 | 1.5875 | 10.4 | 37°25' | 8.7 | 0.7×4 | 2100 / - | 4000 / - | 82 / - |

| FEB 1030 A | 10 | 30 | 1.5875 | 10.4 | 42°33' | 8.7 | 0.7×4 | 2100 / - | 4000 / - | 76 / - |

| Ball Nut Model number | Nut dimension | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nut type | D | Df | L | L1 | F | W | V | Dp | Bolt Hole X | |

| FBS 1003 A | 1 | 24 | 44 | 26 | 20 | 6 | 26 | 27 | 35 | 5.5 |

| FBS 1003 B | 1 | 24 | 44 | 30 | 24 | 6 | 26 | 27 | 35 | 5.5 |

| FBS 1004 A | 1 | 24 | 44 | 29 | 23 | 6 | 26 | 27 | 35 | 5.5 |

| FBS 1004 B | 1 | 24 | 44 | 33 | 27 | 6 | 26 | 27 | 35 | 5.5 |

| FDB 1005 A | 2 | 23 | 40 | 26 | 21 | 5 | - | 25 | 32 | 4.5 |

| FBS 1005 A | 1 | 24 | 44 | 34 | 28 | 6 | 26 | 27 | 35 | 5.5 |

| FEB 1010 A | 3 | 23 | 40 | 24 | 13 | 5 | - | 25 | 32 | 4.5 |

| FEB 1012 A | 3 | 23 | 40 | 28 | 17 | 5 | - | 25 | 32 | 4.5 |

| FEB 1015 A | 3 | 23 | 40 | 33 | 22 | 5 | - | 25 | 32 | 4.5 |

| FEB 1020 A | 3 | 20 | 37 | 23 | 13 | 5 | - | 22 | 29 | 4.5 |

| FEB 1025 A | 3 | 20 | 37 | 27.5 | 17.5 | 5 | - | 22 | 29 | 4.5 |

| FEB 1030 A | 3 | 20 | 37 | 31.5 | 21.7 | 5 | - | 22 | 29 | 4.5 |

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-2: Internal-deflector type or End-deflector type

Type-3: End-cap type or End-deflector type

| Basic Load Rating N | Nut Rigidity N/µm | ||

|---|---|---|---|

| Dynamic Ca | Static Coa | ||

| 1000 / 640 | 3300 / 1650 | 164 / 138 | |

| Preload type | |||

| Backlash type | |||

| Precision Ball Screws | |

|---|---|

Single Nut with Flange | Backlash type/Preload type |

Type-1: Return-plate type

| Unit : mm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ball Nut Model number | Shaft nominal dia. d | Lead | Ball size | BCD | Lead angle | Root dia. d0 | Number of Circuit | Basic Load Rating N | Nut Rigidity N/µm | |

| Dynamic Ca | Static Coa | |||||||||

| FKB 1201 A | 12 | 1 | 0.8 | 12.2 | 1°30' | 11.3 | 1×3 | 780 / 780 | 2000 / 2000 | 97 / 152 |

| FBS 1201 B | 12 | 1 | 0.8 | 12.15 | 1°30' | 11.3 | 3.7×1 | 910 / 570 | 2400 / 1200 | 131 / 110 |